A paper chip for chemiluminescence time-resolved and its fabrication method

A time-resolved, chemiluminescence technology, which is applied in chemical instruments and methods, chemiluminescence/bioluminescence, and analysis by making materials undergo chemical reactions, can solve the problem of inability to change the migration of the solution, the reproducibility and precision of the migration time Not very good and other problems, to achieve the effect of simple method, low cost and good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

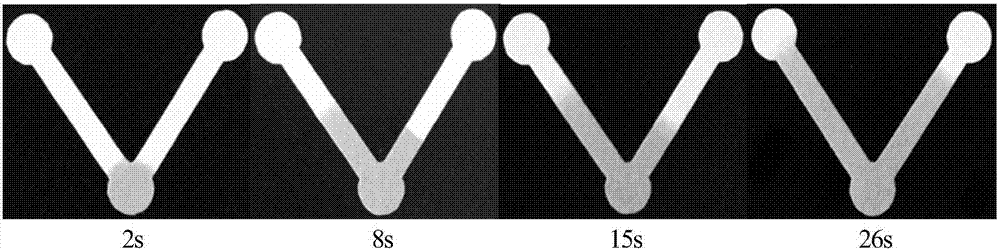

[0023] Firstly, use CorelDraw X6 drawing software to design a paper chip model. The paper chip model has two detection areas with a diameter of 6 mm and a sample area with a diameter of 6 mm. Each area is connected by a flow channel with a width of 3 mm. The length is 16mm; then use the cutting knife of Ritu CE5000-40-CRP cutting plotter to cut out paper chips on Whatman No. 1 filter paper according to the above paper chip model, then replace the cutting knife with a water-based fiber pen, and put the ink in the pen holder Replace it with a mixture of PDMS and dichloromethane at a volume ratio of 1:30, set the starting point of the drawing, and draw three consecutive passages of PDMS and dichloromethane on a flow channel of the paper chip with a water-based drawing pen along the direction perpendicular to the channel. After the dichloromethane is completely volatilized, a 6mm long delay channel is formed, and the coverage of PDMS on the flow channel is 5×10 -5 g / mm 2 , that i...

Embodiment 2

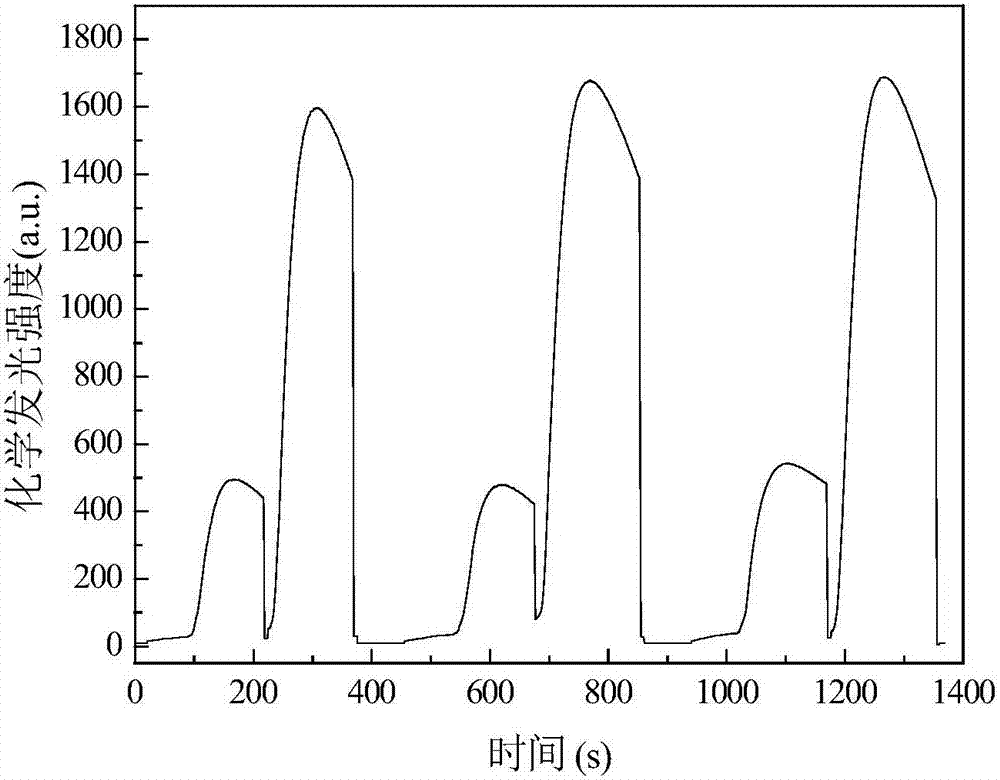

[0026] Firstly, use CorelDraw X6 drawing software to design a paper chip model. The paper chip model has three detection areas with a diameter of 6mm, and a sample area with a diameter of 6mm. The length is 16mm; then use the cutting knife of Ritu CE5000-40-CRP cutting plotter to cut out paper chips on Whatman No. 1 filter paper according to the above paper chip model, then replace the cutting knife with a water-based fiber pen, and put the ink in the pen holder Replace it with a mixture of PDMS and dichloromethane at a volume ratio of 1:30, set the starting point of the drawing, and use a water-based drawing pen to continuously draw 1 and 2 channels on the two flow channels of the paper chip along the direction perpendicular to the channel. For the mixture of PDMS and dichloromethane, when the dichloromethane is completely volatilized, one flow channel forms a 2mm long delay channel, and one flow channel forms a 4mm long delay channel, and the coverage of PDMS on the flow chan...

Embodiment 3

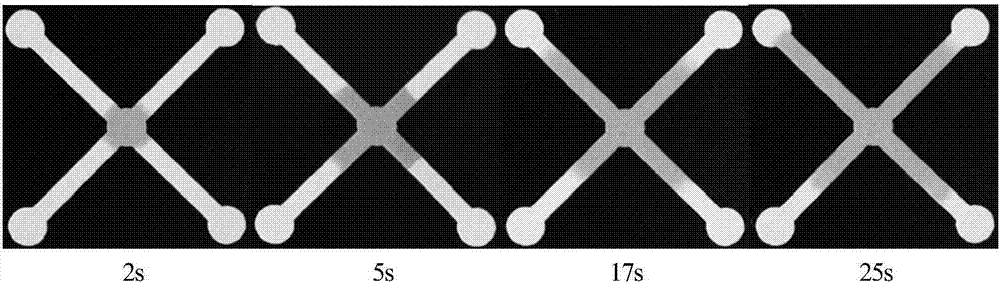

[0028] Firstly, use CorelDraw X6 drawing software to design a paper chip model. The paper chip model has four detection areas with a diameter of 6 mm, and a sample area with a diameter of 6 mm. Each area is connected by a flow channel with a width of 3 mm. The length is 16mm; then use the cutting knife of Ritu CE5000-40-CRP cutting plotter to cut out paper chips on Whatman No. 1 filter paper according to the above paper chip model, then replace the cutting knife with a water-based fiber pen, and put the ink in the pen holder Replace it with a mixture of PDMS and dichloromethane at a volume ratio of 1:30, set the starting point of the drawing, and draw 1 and 2 lanes on the three flow channels of the paper chip with a water-based drawing pen in a direction perpendicular to the channel respectively. , 3 channels of mixed solution of PDMS and dichloromethane. After the dichloromethane is completely volatilized, 2mm, 4mm, and 6mm long delay channels are formed in turn. The coverage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com