Inclined-tooth plastic steel zipper

A zipper and plastic-steel technology, which is applied in the field of improving the structure of the elements of finger zippers, can solve problems such as weak self-locking force, meshing strength, and consumer aesthetic fatigue, so as to meet individual needs, improve occlusal strength, and improve sliders. The effect of simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

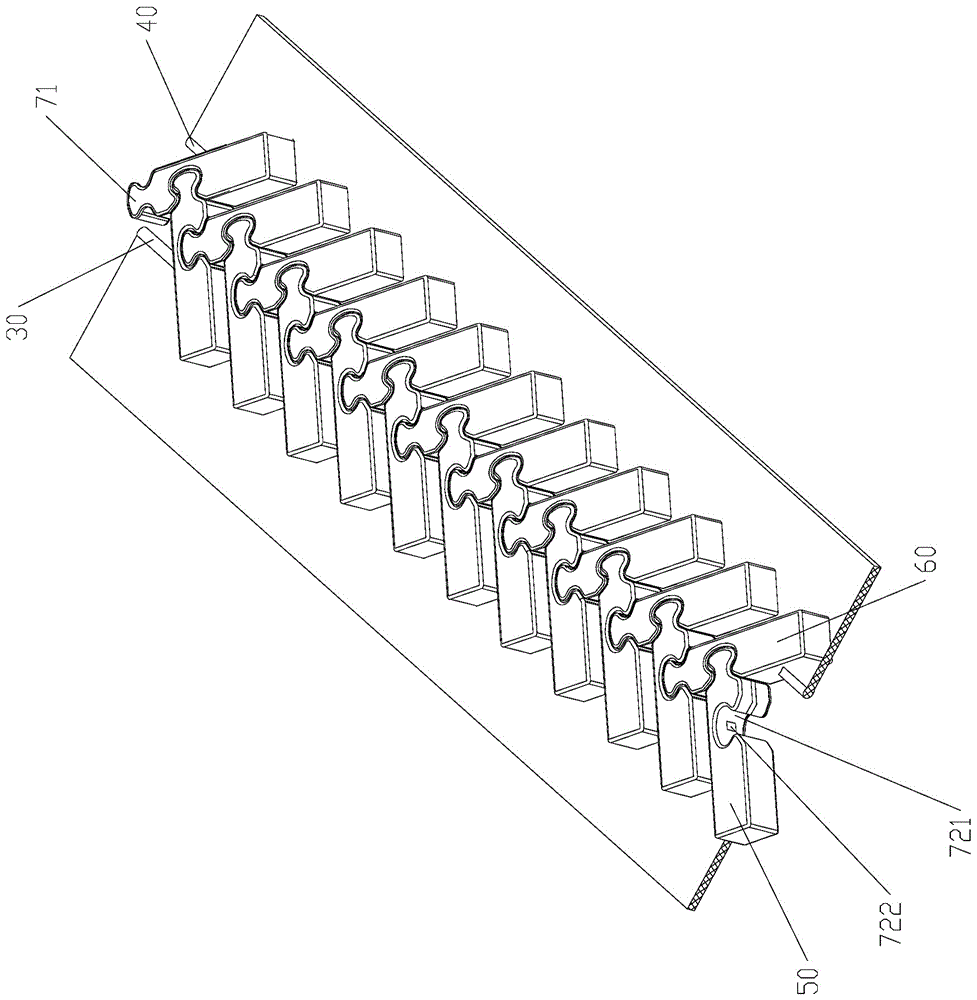

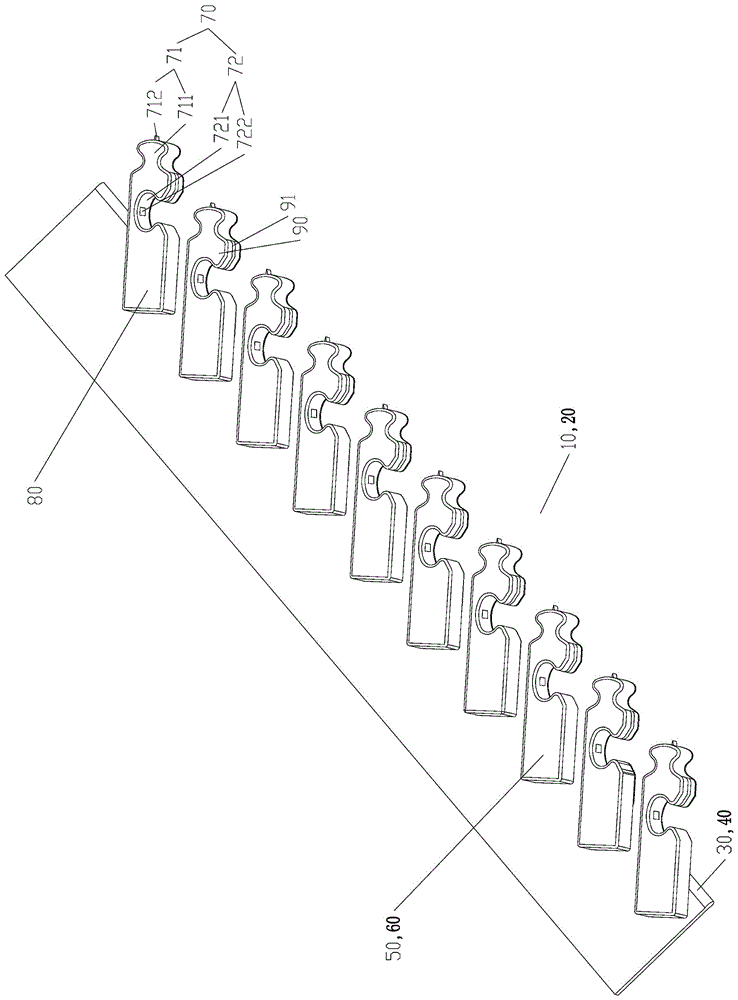

[0017] Such as figure 1 , 2 A kind of oblique teeth plastic-steel zipper shown, the left and right chain teeth 50,60 on the left and right chain embryos 10,20 of the zipper are arranged on the fabric at a certain angle of inclination with the left and right cloth bars 30,40. Bring it on.

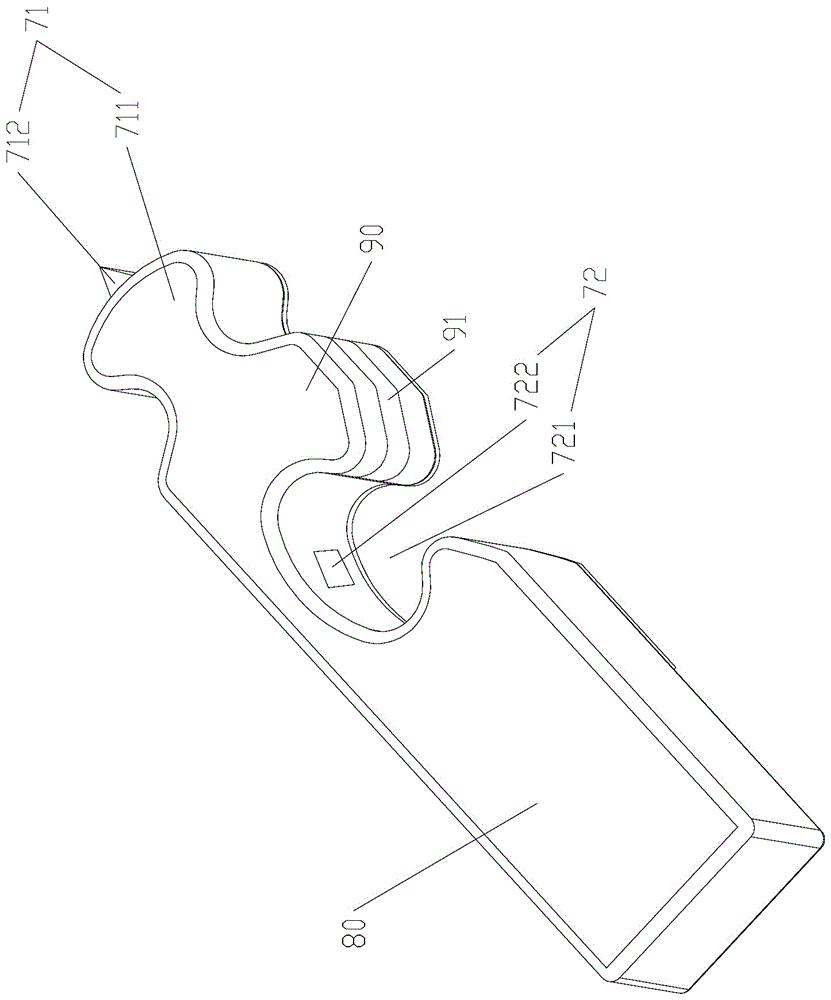

[0018] The concrete structure of chain tooth of the present invention is as image 3 As shown, the fastener element includes an engaging portion 70 where the left and right fastener elements 50 and 60 engage with each other, and an engaging portion 80 fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com