Wheel cover special welding machine

A welding machine and wheel cover technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor effect and easy walking, etc., and achieve the effect of improving welding quality and accommodating manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

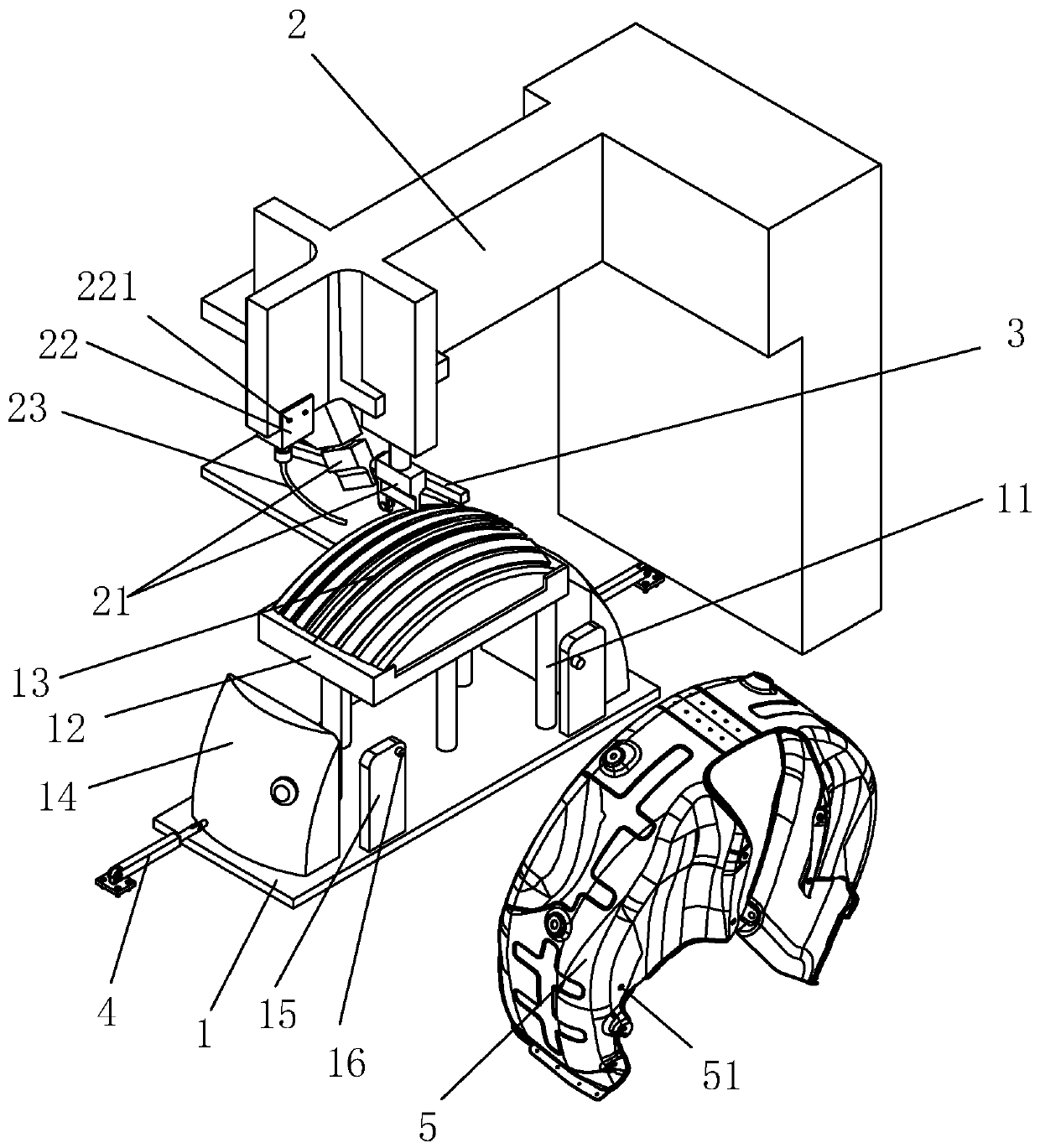

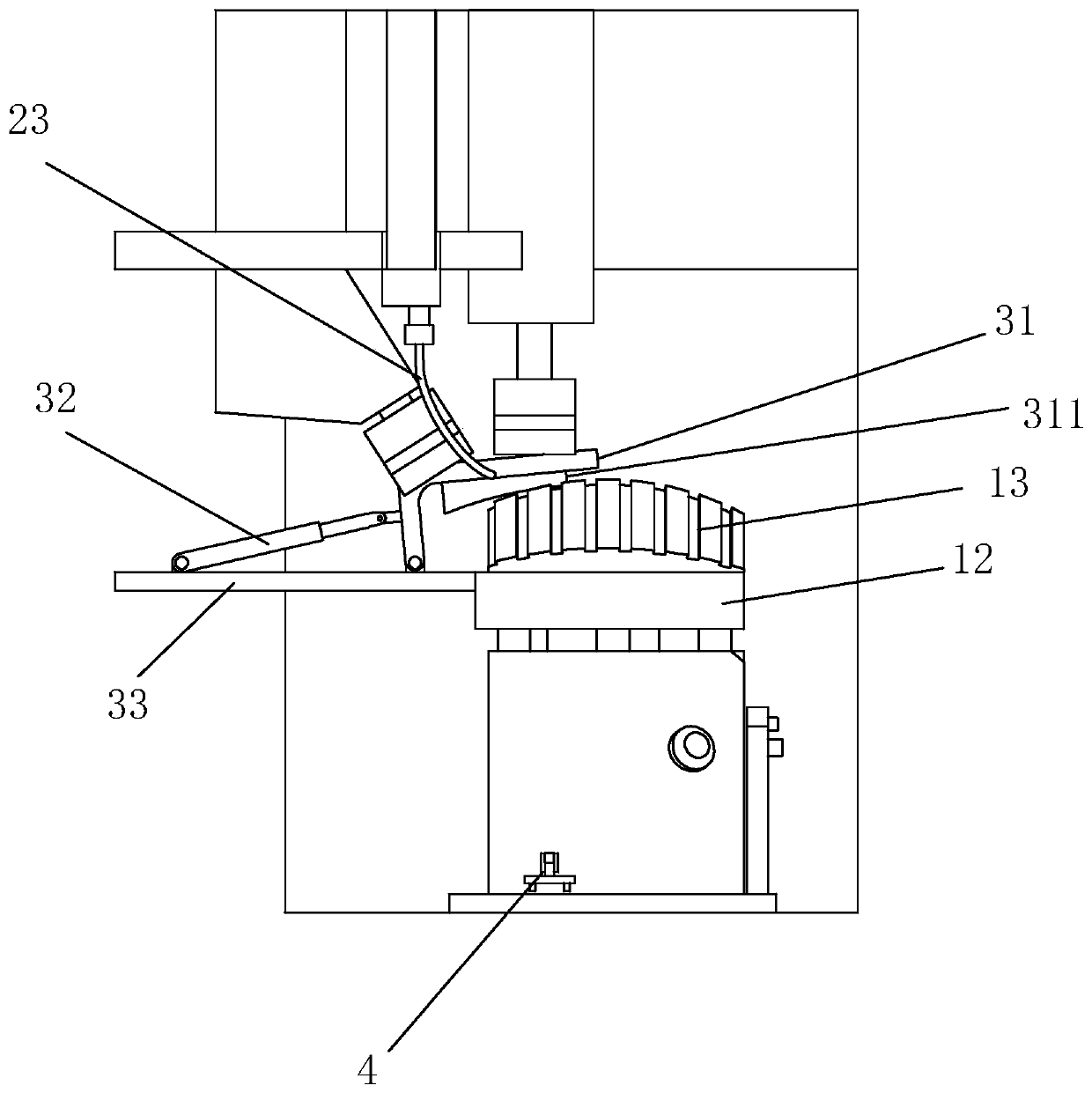

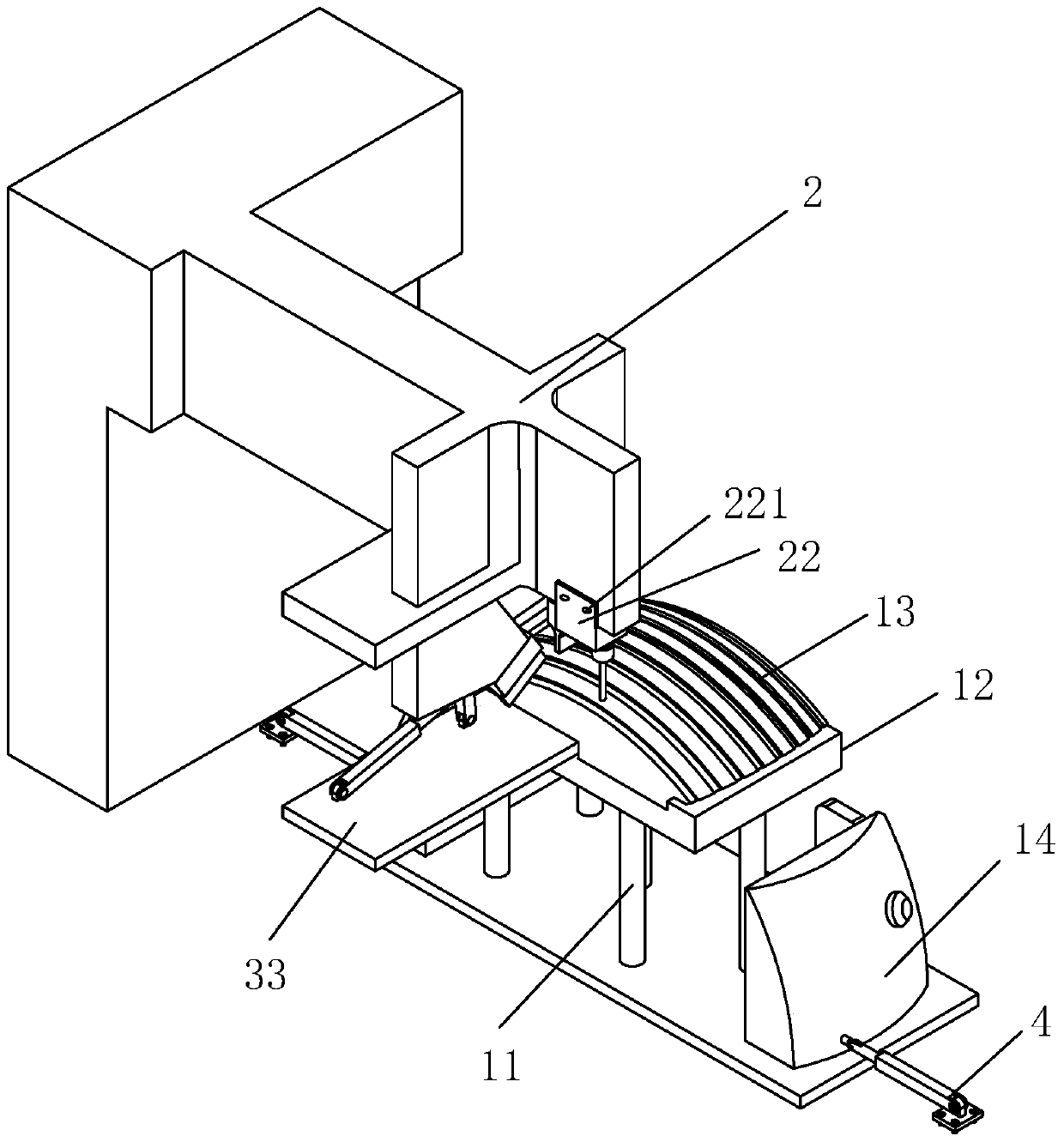

[0035] Embodiment: a special welding machine for wheel covers, which is used to weld two half bodies 5 to form a complete wheel cover. In this embodiment, the position where the operator stands and operates is defined as the front side, the relative position is the rear side, and the directions of the left and right hands of the operator are respectively the left and right sides.

[0036] Such as figure 1 As shown, it includes a base plate 1 , a fixed base 12 , a mold base 13 and a frame 2 , and the base plate 1 and the fixed base 12 are fixedly connected by several support columns 11 . The frame 2 is provided with two ultrasonic welding heads 21, and the ultrasonic welding heads 21 are driven by a cylinder to slide up and down to realize welding and return thereof. The frame 2 is also provided with a mounting block 22, the slot provided on the mounting block 22 is set on the frame 2, and then the mounting hole 221 is passed through the screw to realize installation, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com