Method and system for uniformly controlling laser power

A laser power and uniform control technology, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the process requirements and deficiencies that cannot meet the ablation uniformity of cutting workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

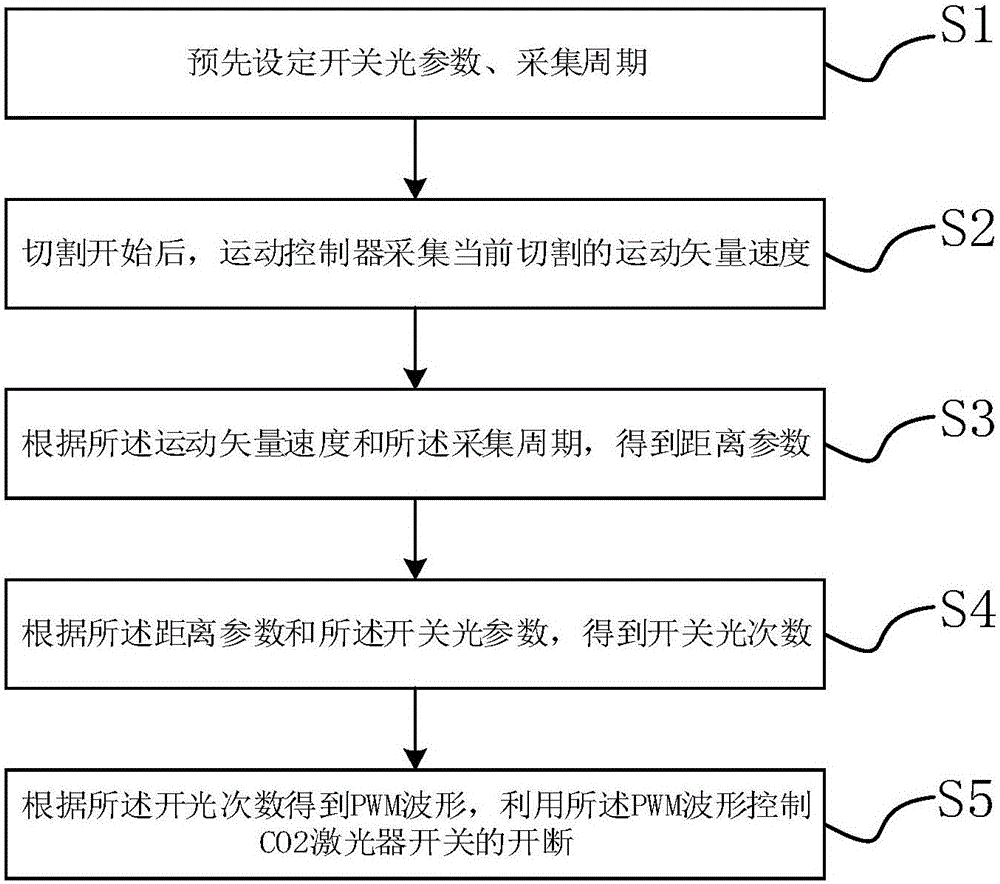

[0037] figure 1 It is a block diagram of a method for uniformly controlling laser power of the present invention, comprising the following steps:

[0038] S1. Preset the switching light parameters and acquisition cycle;

[0039] S2. After the cutting starts, the motion controller collects the motion vector speed of the current cutting;

[0040] S3. Obtain a distance parameter according to the speed of the motion vector and the acquisition period;

[0041] S4. According to the distance parameter and the switch light parameter, obtain the number of switch light;

[0042] S5. Obtain a PWM waveform according to the switching times, and use the PWM waveform to control the switching of the CO2 laser switch, wherein the frequency of the PWM waveform is equal to the switching times.

[0043] The method for uniformly controlling the laser power of the present invention can accurately control the cutting power of the laser tube in real time, so that the process requirement of ablati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com