Cable Retractable System

A cable and cable storage technology, which is applied in the direction of function indication, thin material handling, transportation and packaging, etc., can solve the problem that the cable retracting and unwinding system cannot accurately control the cable pitch, and achieve large starting torque, wide speed regulation range, The effect of smooth stepless speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

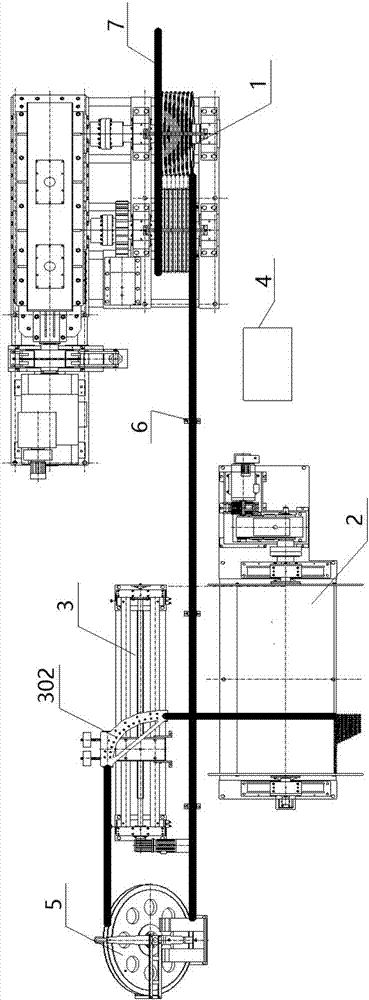

[0037] Such as figure 1 As shown, the present invention provides a cable retracting system, including a traction device 1 fixed on a base 9, a cable storage device 2, a cable discharge device 3 and a control device 4, wherein:

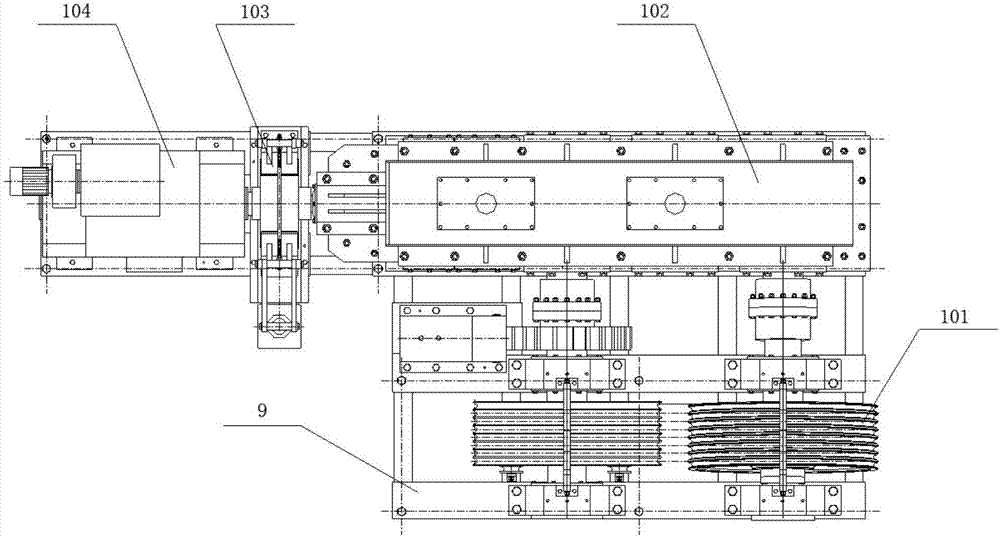

[0038] Such as image 3 As shown, the traction device 1 includes a traction motor 104, a shaft coupling, a traction motor reducer 102, a traction wheel 101, and a traction motor brake 103 located on the base 9; 102 is connected to provide traction power to the traction motor reducer 102, and after deceleration, the traction power is distributed to the traction wheel 101; the traction wheel 101 is used to complete the retraction of the cable 7; The motor brake 103 is connected, and the traction motor brake 103 brakes the traction motor;

[0039] Such as Figure 4 As shown, the cable storage device 2 includes a cable storage motor 201 on the base 9, a cable storage barrel 204, a cable storage motor reducer 203, and a cable storage motor brake 202; the...

specific Embodiment 2

[0059] The cable retracting device for large moored boats is generally fixed in the ground shelter, and is used for the lift-off, parking and recovery operations of the moored boat. The mooring boat is evacuated by cable traction, and the mooring cables are wound on the cable storage barrel in an orderly manner during recovery. Since the net buoyancy of large moored boats generally reaches 2-3t, the maximum tension of the moored cables can reach 14t under the condition of 35m / s wind speed in the air. Under certain conditions, it must also be safe and reliable, including the status of resident, lift-off and recovery.

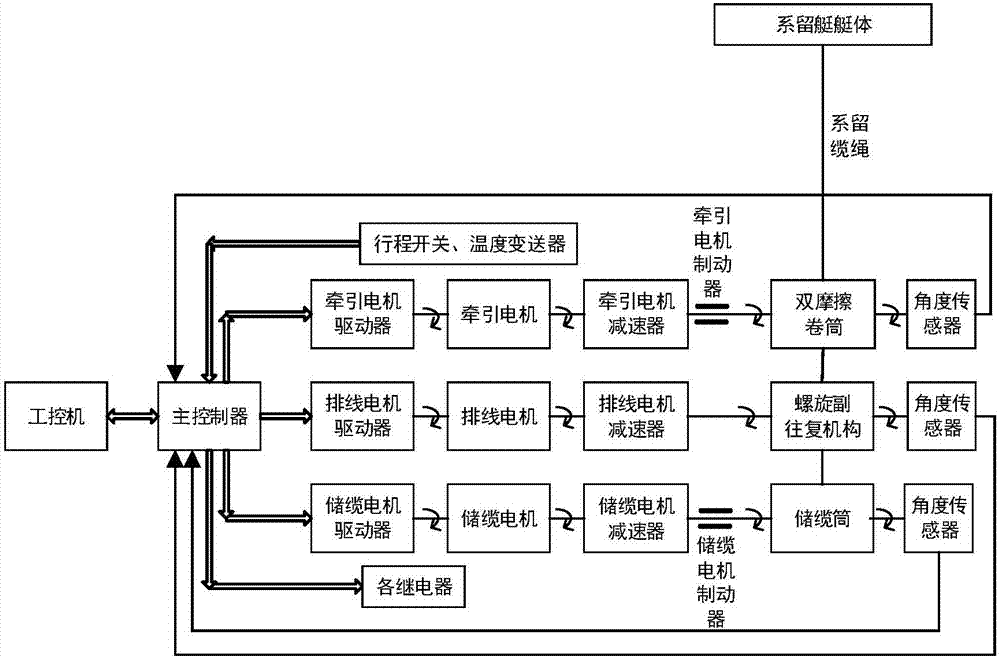

[0060] Such as Image 6 As shown, the embodiment of the present invention provides a system for retracting and unwinding cables. The industrial computer performs tasks such as sending control commands such as cable retracting and unwinding, online monitoring, and data storage through the human-computer interaction interface. The industrial computer is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com