Eight double brocade woven labels with reduced translucent color and its weaving method

A color-transparent and weaving label technology, applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of high waste rate of woven labels, long floating yarn, affecting weaving and shearing processing, etc., and achieve the effect of reducing the phenomenon of color penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

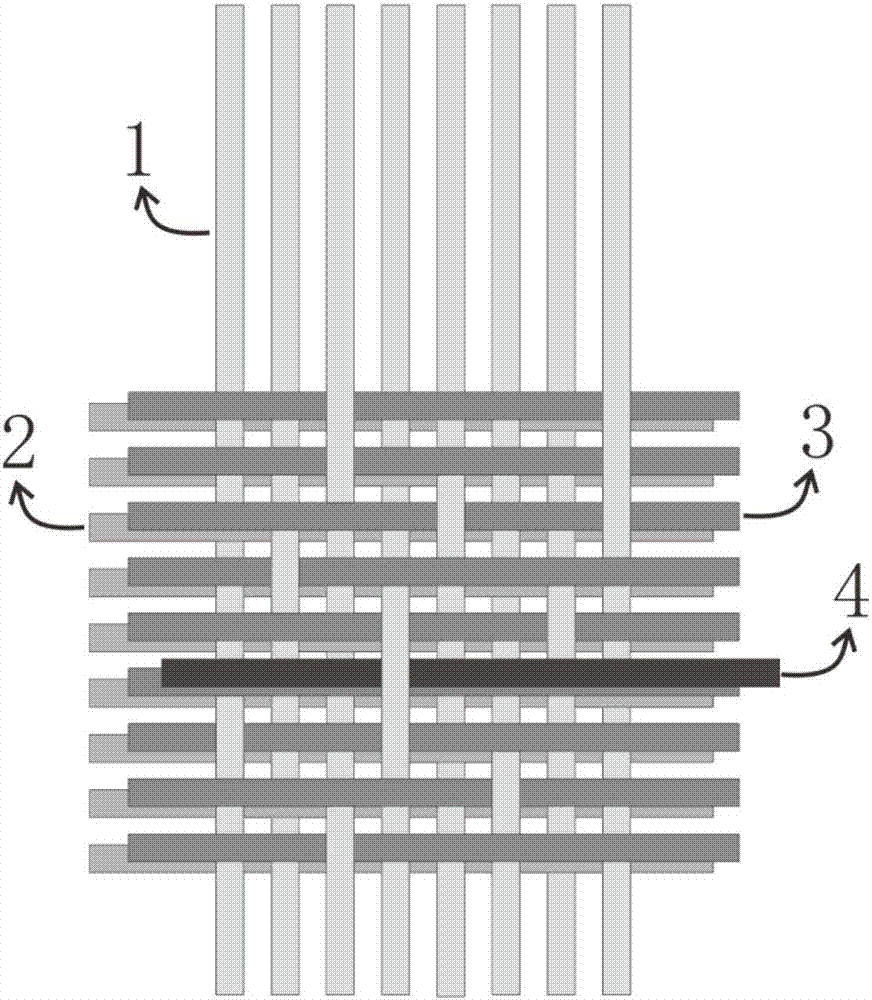

[0066] Example 1 Woven labels woven with 8 pieces of 5-enclave weave + new lining weave + 24 pieces of 5-flying shuttle weave

[0067] The woven label in this embodiment uses 8 pieces of 5 enclave weaves + new lining weave + 24 pieces of 5 flying net shuttle weaves for weaving, specifically including the following steps:

[0068] (1) Before designing the design of the woven label, determine the warp and weft density and yarn thickness of the woven label. The warp density of this embodiment is suitable for 140-152dpi, and the weft density is suitable for 112-228dpi; the warp thickness of the woven label is suitable for 50D-100D, and the weft thickness is suitable for 30D-150D;

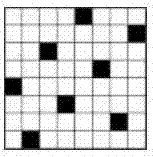

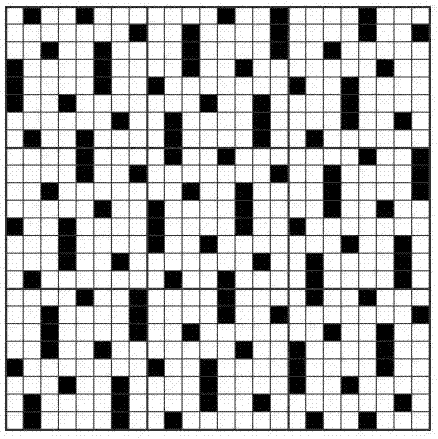

[0069] (2), in the woven label writing flower design software, make a new type of lining organization for 24 5-flying net shuttles: use 8 5-flying land weaves ( figure 2 ) as the basis, the 24 5 flying net shuttle organization ( Figure 4 ), in the 8-5-fly organization ( figure 2 ) is shifted by 1 ...

Embodiment 2

[0074] Example 2 Woven labels woven with 8 pieces of 3 enclave weave + new lining weave + 24 pieces of 19 flying net shuttle weave

[0075] The woven label in this embodiment uses 8 pieces of 3 enclave weaves + new lining weave + 24 pieces of 19 flying mesh shuttle weaves, specifically including the following steps:

[0076] (1) Before designing the design of the woven label, determine the warp and weft density and yarn thickness of the woven label. The warp density of this embodiment is suitable for 140-152dpi, and the weft density is suitable for 112-228dpi; the warp yarn thickness of the woven label is suitable for 50D ~100D, weft thickness is suitable for 30D~150D;

[0077] (2) In the woven label design software, make a new type of lining structure for 24 19 flying net shuttles: use 8 3 enclaves ( Figure 6 ) as the basis, the net shuttle organization 24 19 fly ( Figure 8 ), in the 8-piece 3-fly organization ( Figure 6 ) is shifted by 1 tissue point up and down, formi...

Embodiment 3

[0082] Example 3 Woven label woven with 8 pieces of 5-flying shuttle weave + new lining structure + 24 pieces of 5-flying shuttle weave + 48 pieces of 5-flying shuttle weave + 96 pieces of 53-femling large-network

[0083] The woven label in this embodiment is woven with 8 pieces of 5-flying shuttle weave + new lining structure + 24 pieces of 5-flying shuttle weave + 48 pieces of 5-flying shuttle weave + 96 pieces of 53-femling large netting weaving , including the following steps:

[0084] (1) Before designing the design of the woven label, determine the warp and weft density and yarn thickness of the woven label. In this example, the warp density is suitable for 140-152dpi, and the weft density is suitable for 112-228dpi; the thickness of warp yarn for woven labels is suitable for 50D-100D, and the thickness of weft yarn is suitable for 30D-150D.

[0085] (2), in the woven label writing flower design software, make a new lining structure for 24 5-fly net shuttles: use 8 5-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com