Manufacturing method of bright-colored cloth used for travelling bags

A manufacturing method and technology for travel bags, applied in textiles, papermaking, yarn and other directions, can solve the problem that the glossy color cannot be maintained for a long time, and achieve the effect of lasting glossy color characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for manufacturing a bright color cloth used for a travel bag, the steps are as follows:

[0018] 1) Soak the blended fiber in the bright color forming agent, the soaking temperature is 55°C, the soaking time is 10h, and then dried after soaking.

[0019] The bright color forming agent consists of 10 parts of dibutyl phthalate, 7.5 parts of petroleum ether, 3 parts of bridging agent, 3 parts of film-forming aid, 3 parts of silane coupling agent, 3 parts of anti-sticking agent and 12.5 parts of pearlescent Made by mixing powder.

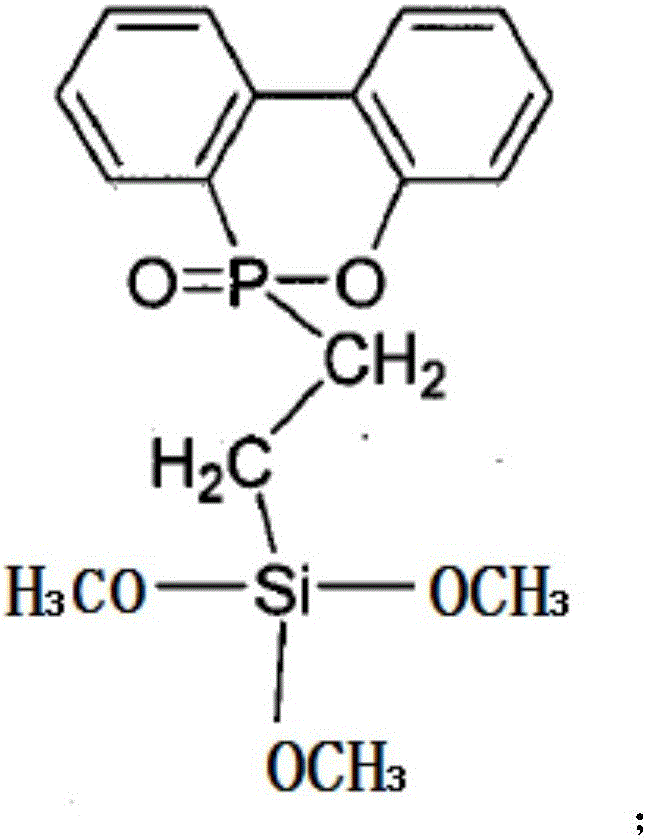

[0020] The structural formula of the silane coupling agent is:

[0021]

[0022] 2) Process the blended fibers into blended fabrics.

[0023] 3) Brush a layer of waterproof glue on the blended fabric, the amount of brushing is 210g / m 2 .

[0024] 4) Perform plasticizing treatment on the blended fabric, the plasticizing time is 10 hours, and the plasticizing temperature is 180°C.

Embodiment 2

[0026] A method for manufacturing a bright color cloth used for a travel bag, the steps are as follows:

[0027] 1) Soak the blended fiber in the glossy color forming agent, the soaking temperature is 40°C, the soaking time is 15h, and then dried after soaking.

[0028] Bright color forming agent consists of 5 parts of dibutyl phthalate, 10 parts of petroleum ether, 1 part of bridging agent, 5 parts of film-forming aid, 1 part of silane coupling agent, 5 parts of anti-sticking agent and 10 parts of pearlescent Made by mixing powder.

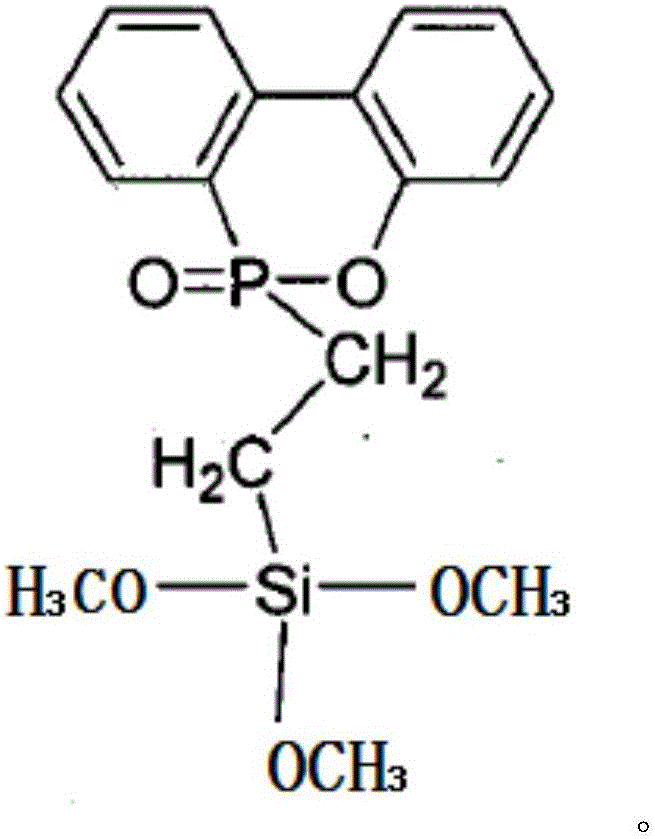

[0029] The structural formula of the silane coupling agent is:

[0030]

[0031] 2) Process the blended fibers into blended fabrics.

[0032] 3) Brush a layer of waterproof glue on the blended fabric, the amount of brushing is 250g / m 2 .

[0033] 4) Perform plasticizing treatment on the blended fabric, the plasticizing time is 5 hours, and the plasticizing temperature is 210°C.

Embodiment 3

[0035] A method for manufacturing a bright color cloth used for a travel bag, the steps are as follows:

[0036] 1) Soak the blended fiber in the bright color forming agent, the soaking temperature is 70°C, the soaking time is 5h, and then dried after soaking.

[0037] Bright color forming agent consists of 15 parts of dibutyl phthalate, 5 parts of petroleum ether, 5 parts of bridging agent, 1 part of film-forming aid, 5 parts of silane coupling agent, 1 part of anti-sticking agent and 15 parts of pearlescent Made by mixing powder.

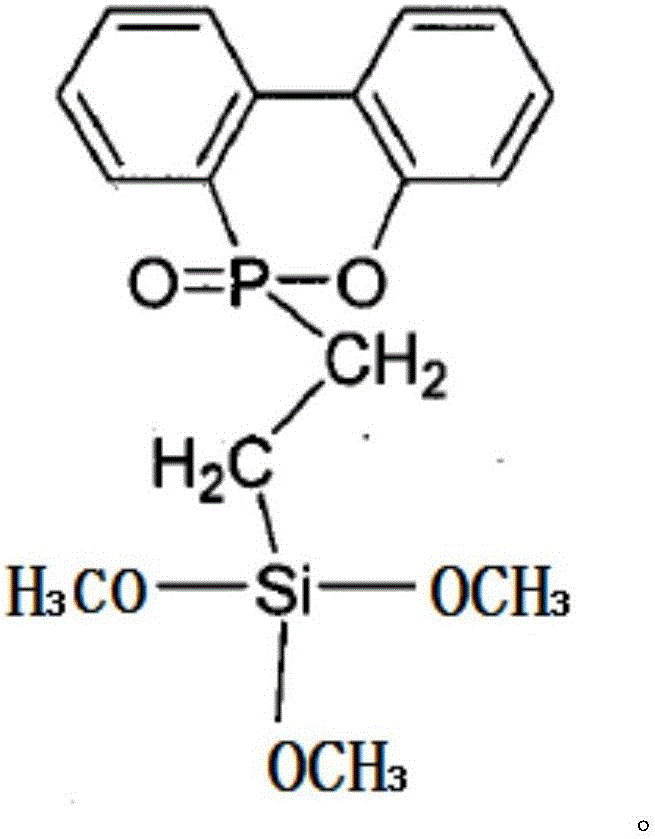

[0038] The structural formula of the silane coupling agent is:

[0039]

[0040] 2) Process the blended fibers into blended fabrics.

[0041] 3) Brush a layer of waterproof glue on the blended fabric, the amount of brushing is 170g / m 2 .

[0042] 4) Perform plasticizing treatment on the blended fabric, the plasticizing time is 15 hours, and the plasticizing temperature is 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com