Soil blocking plate for channel tunneling machine

A technology of underground excavator and earth retaining board, which is applied in tunnels, earth square drilling, mining equipment, etc., and can solve problems such as large manpower and material resources, inconvenience of vehicles moving forward, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

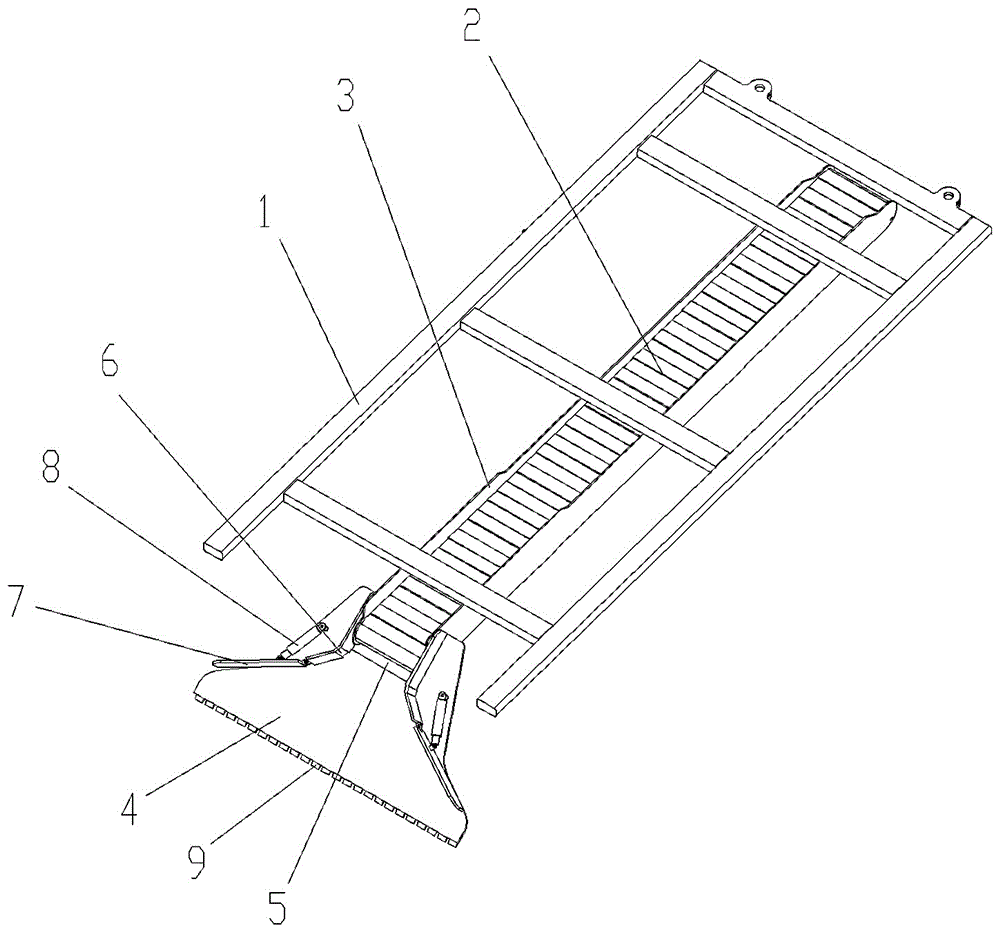

[0016] In order to make the present invention clearer, the device will be described in detail below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

[0017] like figure 1 As shown, the present invention provides a soil retaining plate for tunnel excavators, including a vehicle frame 1, a transmission belt 2 is longitudinally connected below the vehicle frame 1, and the transmission belt 2 adopts a belt-type transmission belt, and both sides of the transmission belt 2 are Connect the first baffle plate 3, the upper edge of the first baffle plate 3 is higher than the transmission belt 2, and the two first baffle plates 3 can prevent the earth on the transmission belt 2 from falling.

[0018] On the two first baffle plates 3 on the front side of the transmission belt 2, the shoveling plate 4 is hinged. The shoveling plate 4 is a trapezoidal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com