Rigidity-improved spherical hinge and method for improving rigidity of spherical hinge

A ball joint and stiffness technology, applied in the field of improving the stiffness of the ball joint, can solve the problems of large space occupation, heavy product, large strain, etc., and achieve the effect of improving stiffness and fatigue resistance, improving fatigue resistance, and increasing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

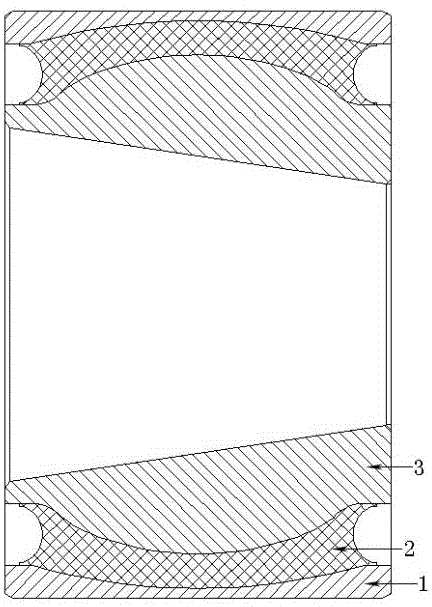

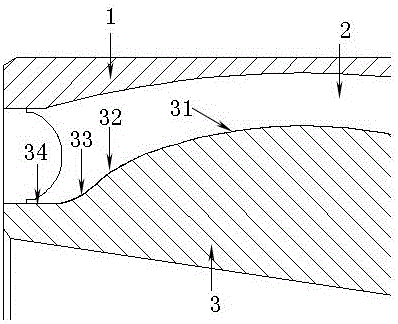

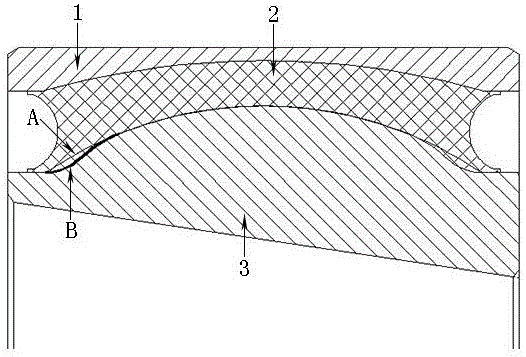

[0031] Such as figure 1 and figure 2 As shown, the outer casing 1, the rubber layer 2 and the mandrel 3 of the ball joint are all rotating bodies, the outer casing 1 and the mandrel 3 are metal parts, and the outer casing 1, the mandrel 3 and the rubber layer 2 are vulcanized together. The peripheral surface of the mandrel 3 includes a main arc segment 31 , an outer convex arc segment 32 , an inner concave arc segment 33 and an annular straight segment 34 . Both sides of the main arc section 31 are provided with two outwardly convex arc sections 32 , but the arc radius of the outwardly convex arc section 32 is smaller than that of the main arc section 31 . The outer side of the convex arc segment 32 is provided with an inner concave arc segment 33 which is concave inward, and the outer side of the inner concave arc segment 33 is also provided with an annular straight segment 34 .

[0032] Wherein the main circular arc section 31, the convex circular arc section 32 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com