refrigerator

A refrigerator and a chute technology, applied in the field of refrigerators, can solve the problems of insufficiently fastened shelves, increase the cost of the shelves, and be unfavorable for popularization and use, and achieve the effects of convenient operation, improved bearing capacity, and reduced bending deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

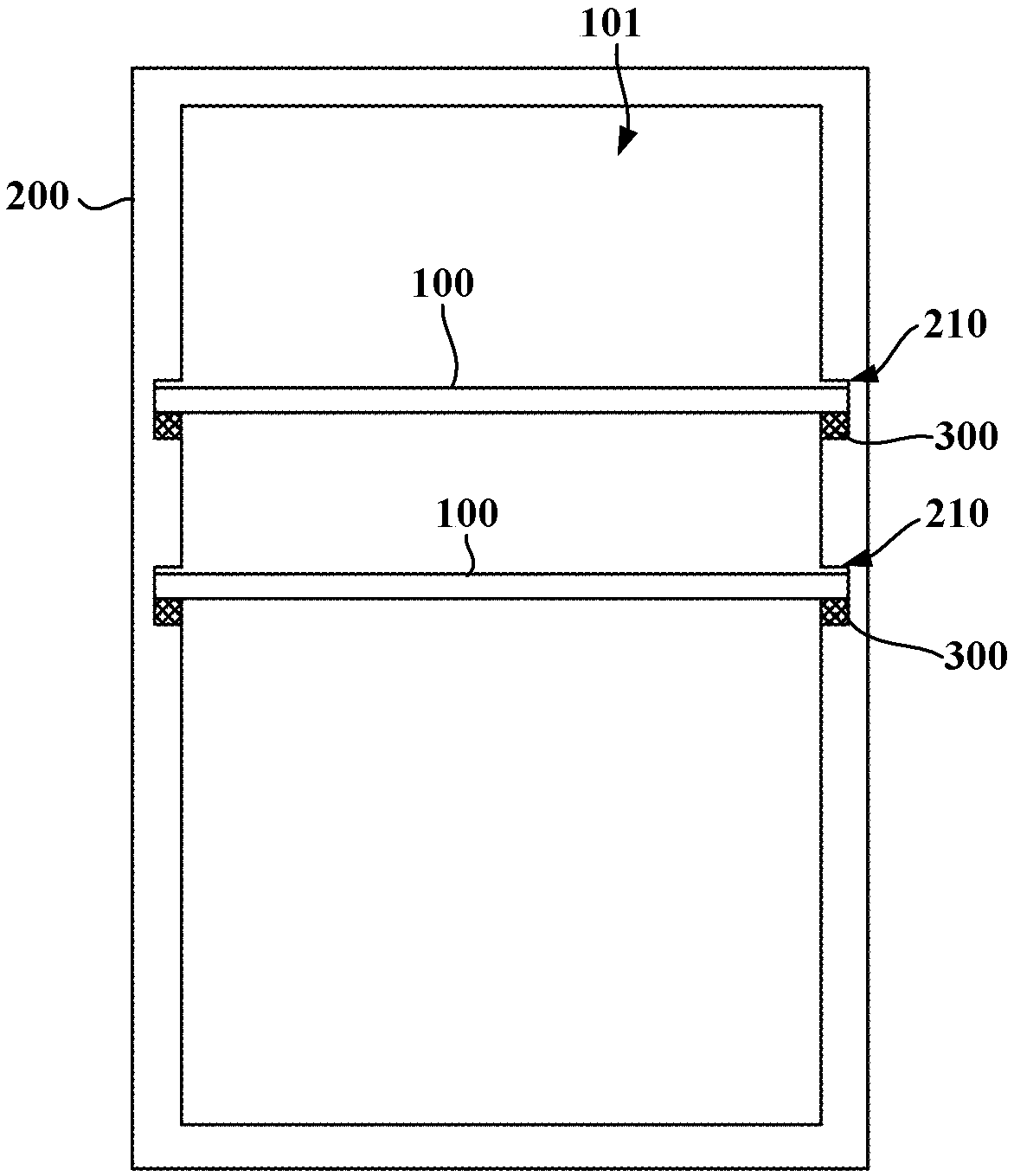

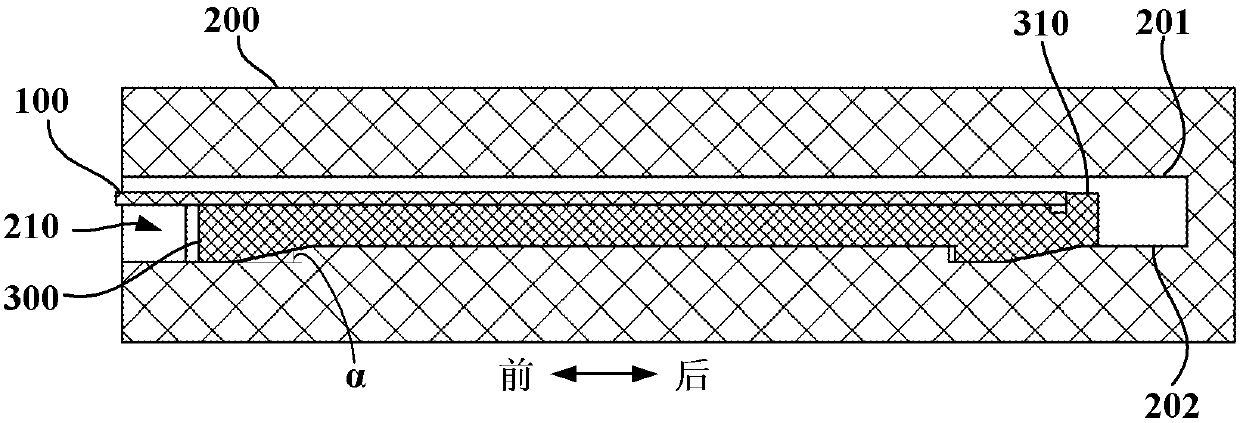

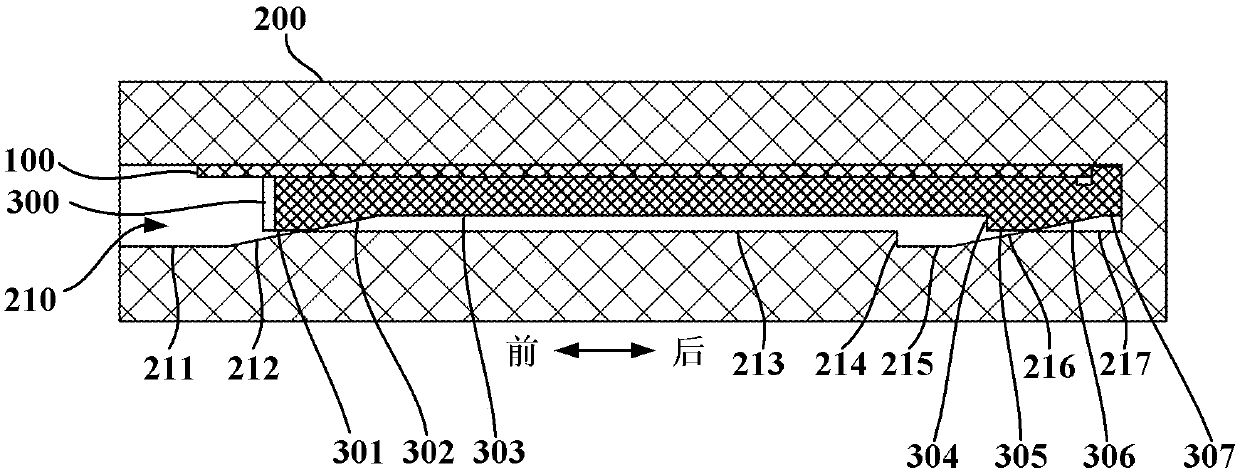

[0024] figure 1 is a schematic front view of a refrigerator according to an embodiment of the present invention; figure 2 will be figure 1 A schematic diagram of the chute of the refrigerator shown cut by a vertical plane extending back and forth, wherein the shelf 100 is not clamped; image 3 will be figure 2 The schematic diagram of when the shelf 100 and the slider 300 move backward so that the shelf 100 is clamped. Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a refrigerator, which includes a storage room 101 and a shelf 100 disposed in the storage room 101 for placing items. Wherein, the storage room 101 is defined by an inner container 200 . In order to facilitate the installation of the shelf 100 , two lateral inner walls of the storage room 101 are provided with sliding grooves 210 opening toward the interior of the storage room 101 , and two lateral edges of the shelf 100 are respectively arranged in the two sliding gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com