Special-shaped tapered double-sided key board manufacturing method

A production method and key board technology, which are used in chemical/electrolytic methods to remove conductive materials, printed circuit manufacturing, electrical components, etc. problem, to achieve the effect of independent connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

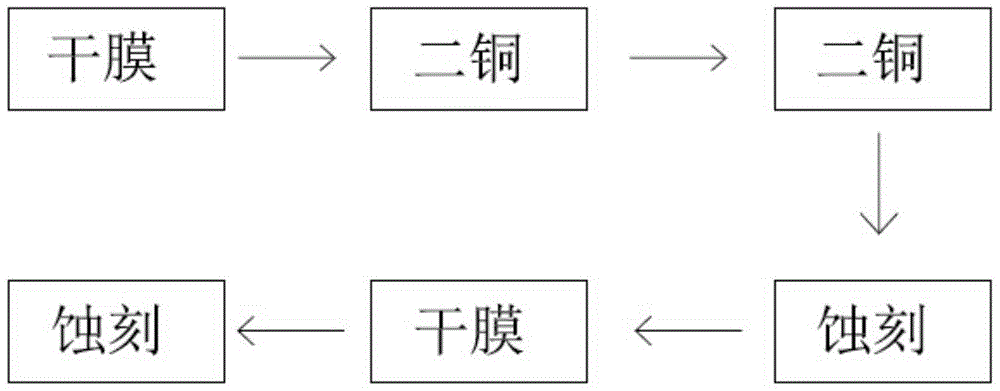

[0020] Such as figure 1 As shown, the manufacturing method of the special-shaped tower-type double-sided key board of the present invention discloses a manufacturing method of a double-sided key board with different copper thickness, which includes the following steps:

[0021] S1 (dry film): First, dry film is applied on the parts that need to be thickened on each bottom copper surface of the key board, so as to produce a stable substance that adheres to the bottom copper surface;

[0022] S2 (second copper): After the dry film, electroplating is performed on various parts of the key board to form a layer of metal film;

[0023] S3 (dry film): Then cover the special-shaped bottom copper surface, and make a pattern on the same-type bottom copper surface;

[0024] S4 (etching): Then confirm that the thickness of the same-sex bottom copper is normally negatively etched;

[0025] S5 (dry film): Then cover the etched bottom copper surface of the same sex, and then make a pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com