A main shaft device

A spindle device, the technology of the spindle, which is applied in the directions of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as the inability to ensure the reliability of the spindle and the reduction of the recovery space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

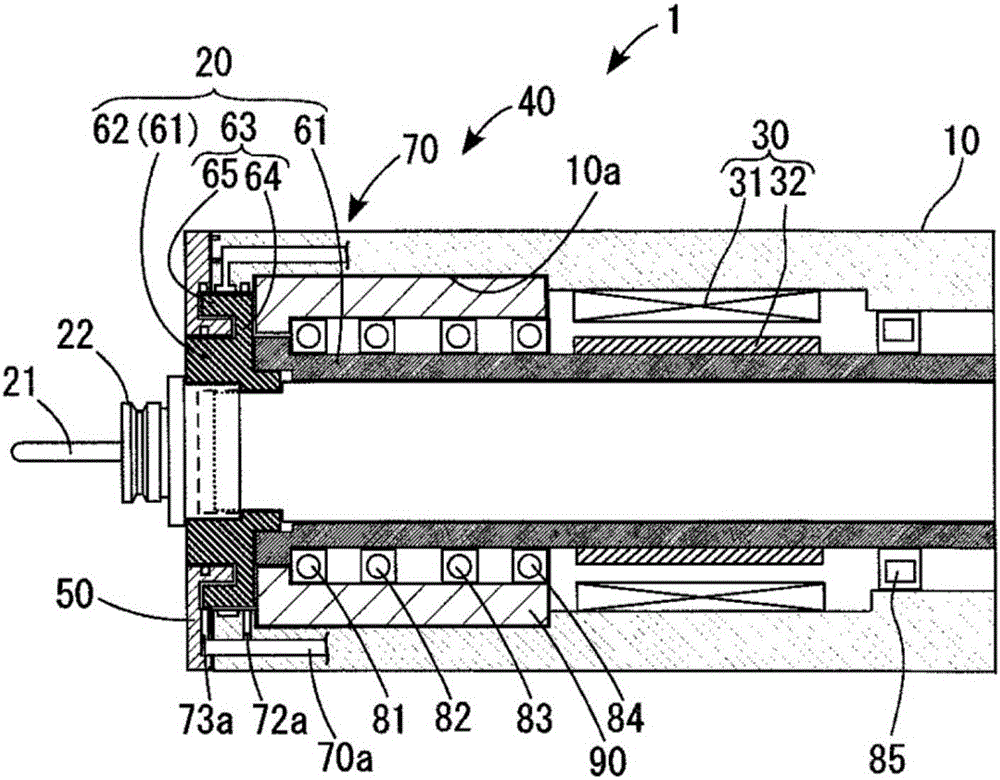

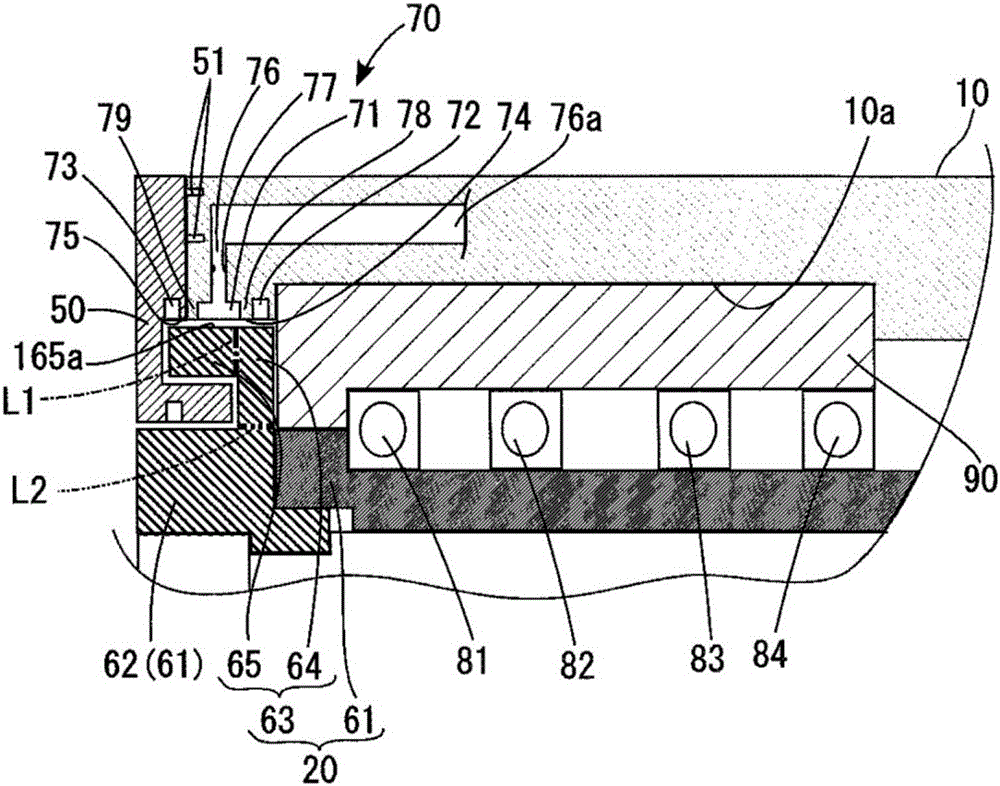

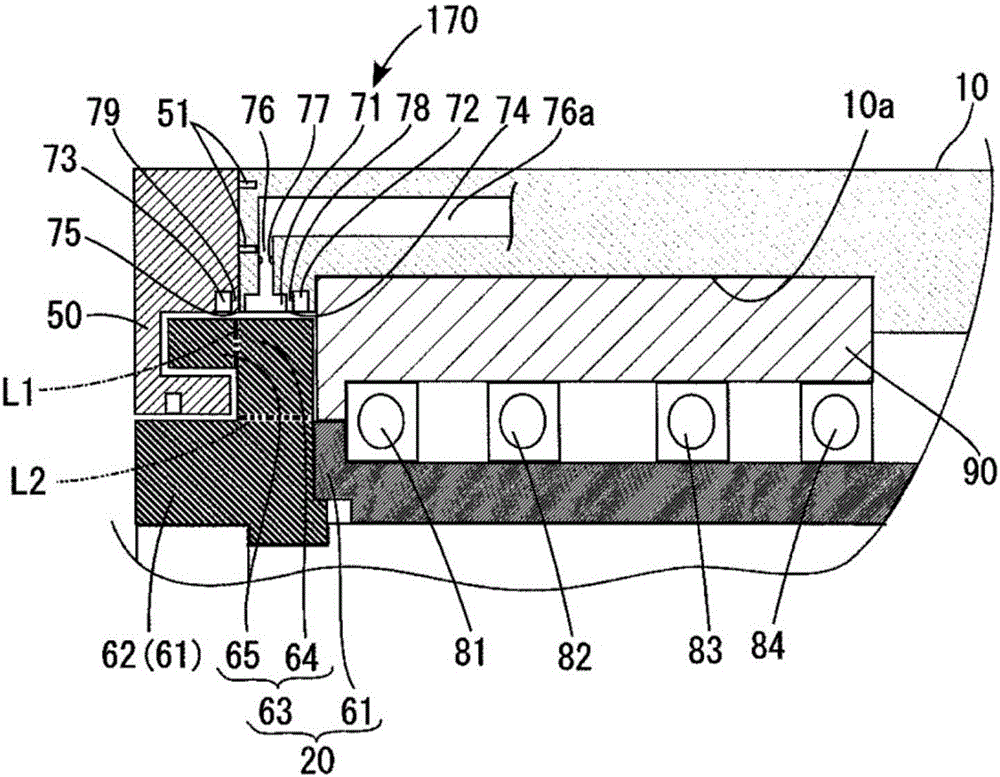

[0020] Hereinafter, a first embodiment of a spindle device according to the present invention will be described with reference to the drawings. For the structure of the spindle device, refer to figure 1 Be explained. Such as figure 1 As shown, the spindle device 1 includes a housing 10, a spindle 20, a motor 30, a support device 40, and a cover 50 (corresponding to a shielding member). In addition, in the description of the spindle device 1, the figure 1 The left side is called the front side, and the figure 1 The right side is called the posterior side.

[0021] The housing 10 is formed in a hollow cylindrical shape through which the main shaft 20 can be inserted. The motor 30 is disposed in the cylinder of the housing 10 and includes a stator 31 fixed to the housing 10 and a rotor 32 fixed to the main shaft 20 . The support device 40 rotatably supports the main shaft 20 with respect to the casing 10 . The support device 40 includes a hydrostatic bearing 70 (correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com