A distributing system and distributing process of imitation natural stone ceramic tiles

A technology of imitating natural stone and fabric distribution system, which is applied in the field of imitation natural stone ceramic tile distributing system and its distributing process. Simple structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

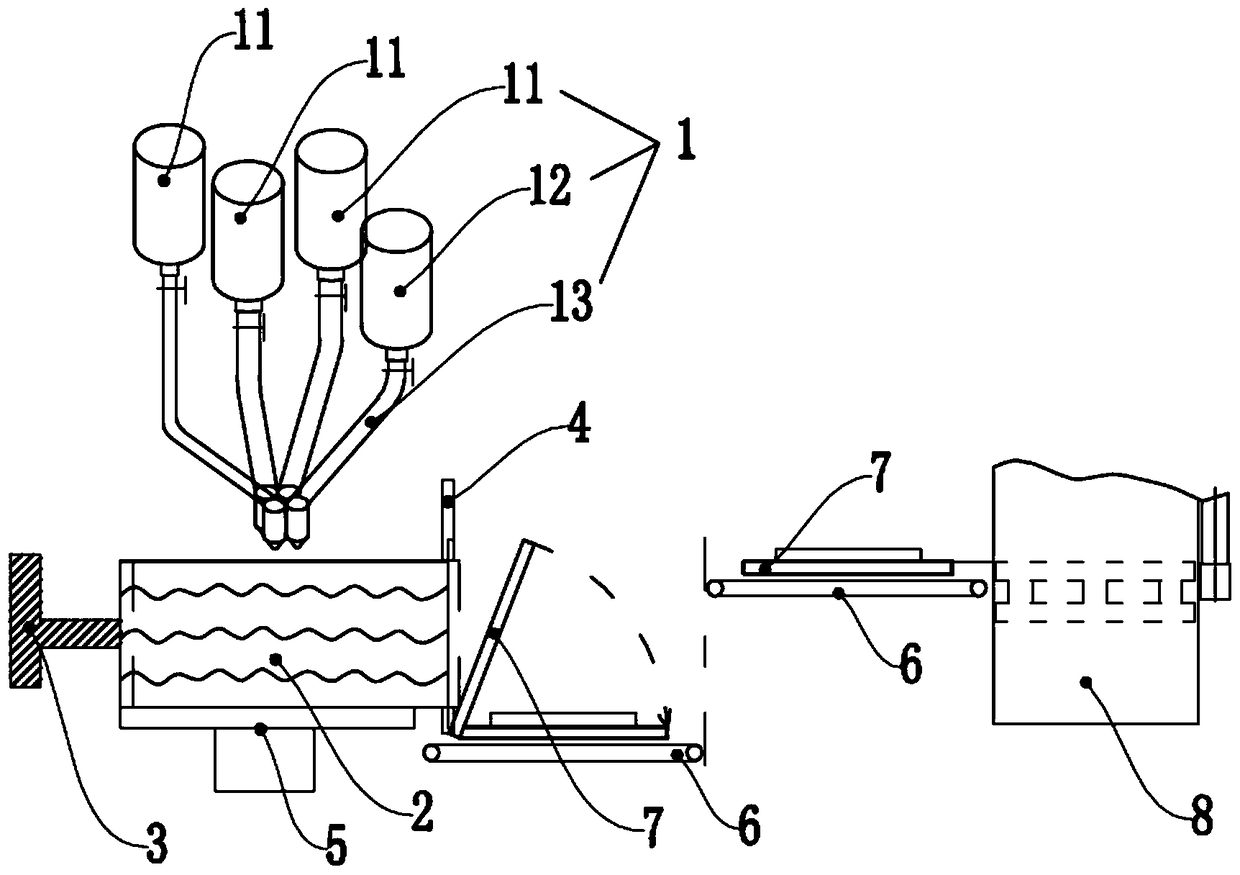

[0050] Preparation of mud material: mix the base material with colorants of different colors, and put each mixed material into their respective mud mixers 11, and add appropriate amount of water in each mud mixer 11 for mud mixing to form different colors mud, spare;

[0051] Put the powder into the powder tank for later use;

[0052] B. The mud material in the mud mixer 11 is distributed in the solid material box 2 to form a mud material layer through the discharge port of the material distribution pipeline 13 provided with a valve;

[0053] C, the powder in the powder tank 12 is provided with a distribution pipeline 13 with a valve on the upper surface of the bottom mud of the solid material box 2 to lay a thin layer of powder that forms a fine line of texture;

[0054] D. Repeat the above step C and step D until a mud mound with a predetermined cloth thickness is obtained;

[0055] E. The mud pier is aged in the solid material box 2. After the aging is completed, the righ...

Embodiment

[0061] The production of a 80*80cm imitation natural stone ceramic tile includes the following procedures:

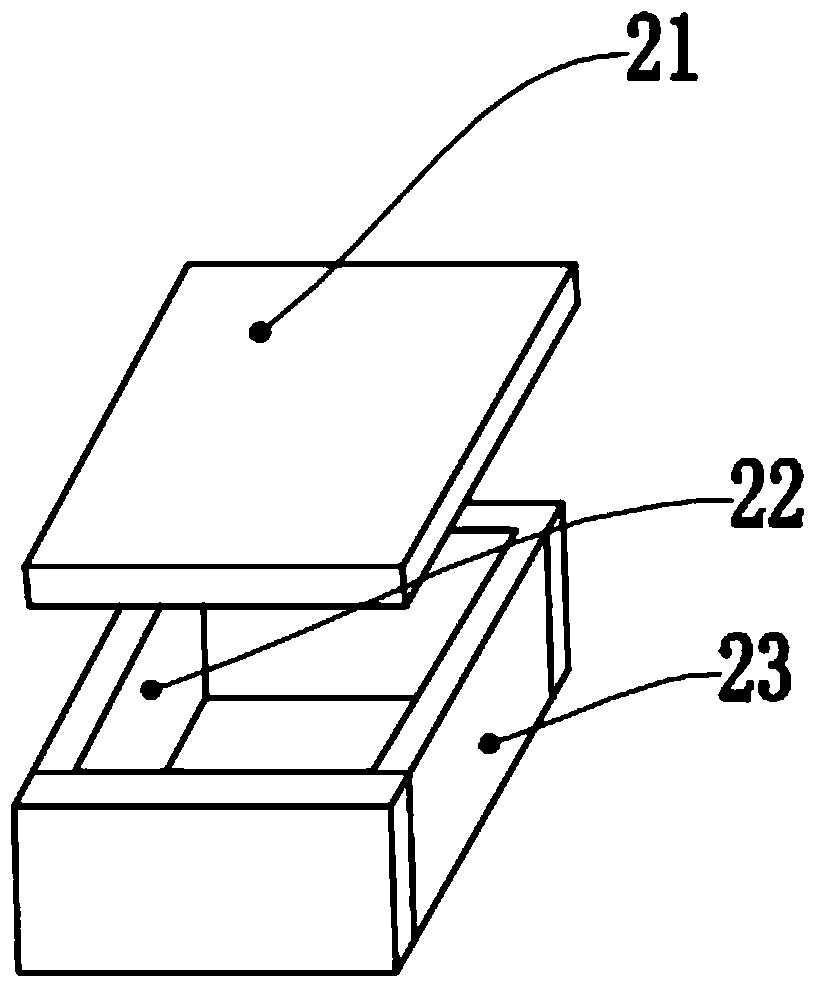

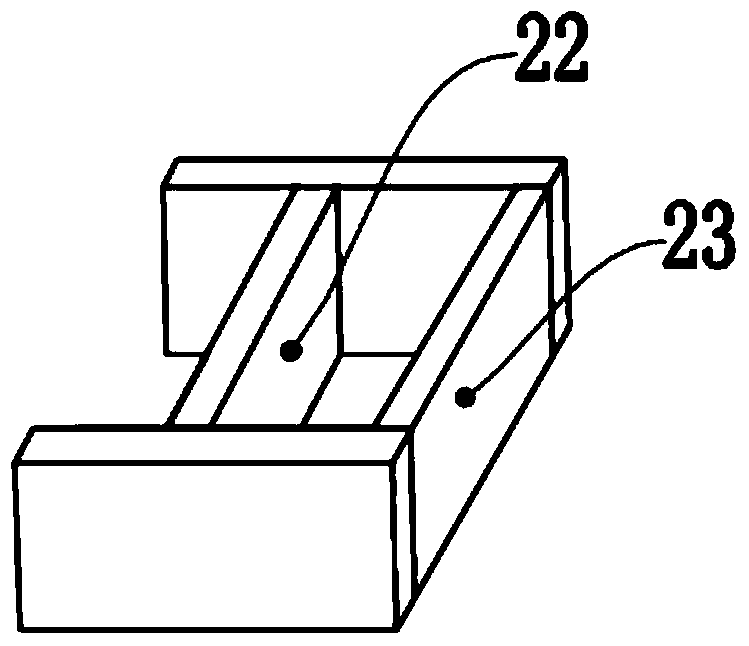

[0062] (1) Preparation of the solid material box: make a cuboid material box with a length*width*height of 100*85*85cm, a top cover and side panels that can be disassembled;

[0063] (2) Preparation of green body raw materials:

[0064] Formula of basic powder: black mud 16%, ball soil 2%, washed potassium sodium sand 16%, washed sodium stone 19%, Dongdao sand 19%, potassium sand 26%, calcined talc 3.6%, PVA 0.03%, 0.25% lignin, 0.375% water reducer; preparation: take the material and put it into a ball mill for ball milling, after ball milling, spray dry it into a fine powder to obtain the basic powder;

[0065] The ratio of 3 kinds of mud and 1 kind of powder to be prepared is as follows:

[0066] Mud 1: basic powder + orange-yellow material with 0.3% of the mass of the basic powder

[0067] Mud 2: basic powder + orange-red material with 0.05% of the mass of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com