Spray driving device and spray system

A driving device and spray system technology, applied in the direction of electrical program control, program control in sequence/logic controllers, etc., can solve the problems of discarding sprayers, inability to optimize the spray effect of sprayers, waste of energy, etc., and achieve optimized spraying. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] For the detailed description and technical content of the present invention, please refer to the following detailed description and accompanying drawings as follows, and the accompanying drawings and detailed description are for illustration purposes only, and are not intended to limit the present invention.

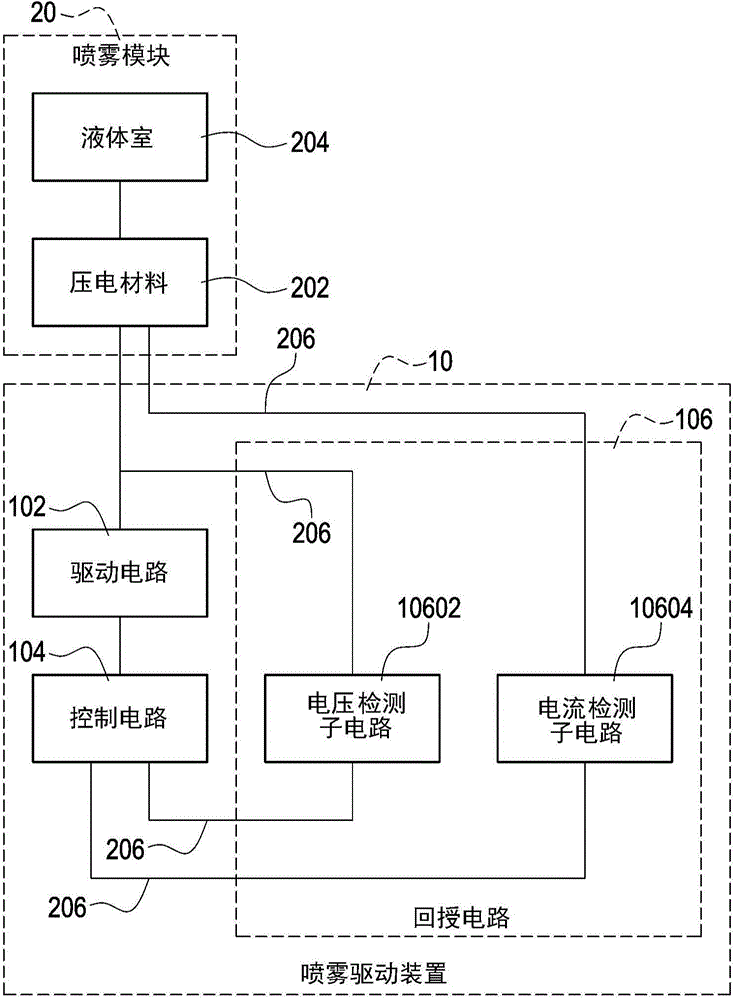

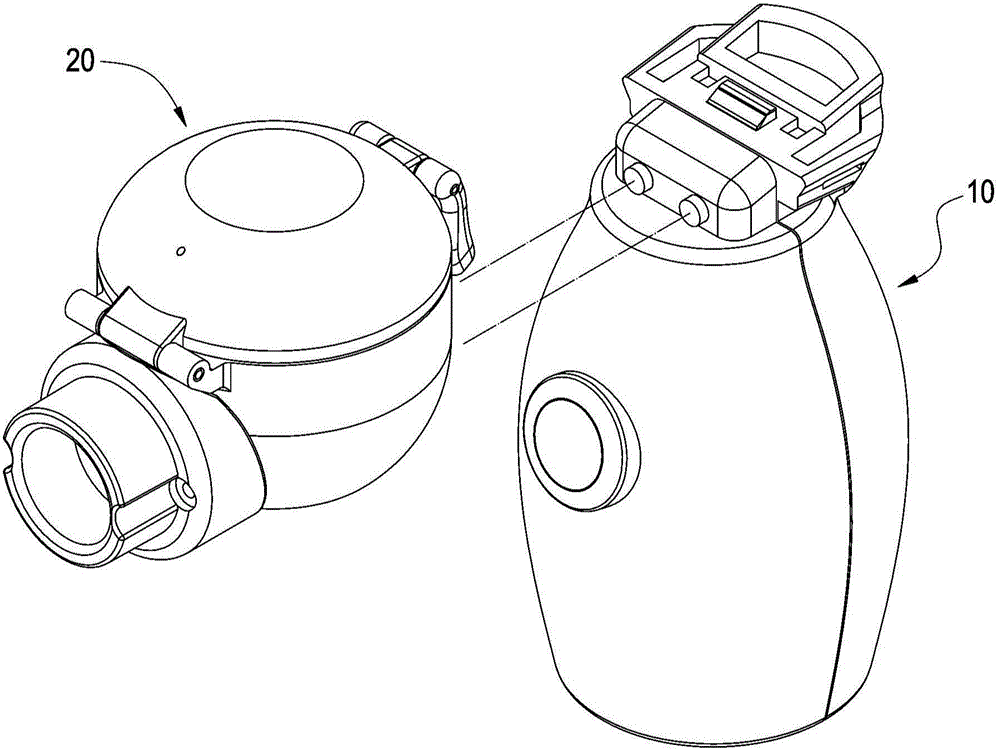

[0076] Please refer to figure 1 , which is a block diagram of the spray driving device of the present invention; please refer to figure 2 , which is a combined appearance diagram of the spray driving device of the present invention. A spray driving device 10 is used to drive a piezoelectric material 202 of a spray module 20; the spray module 20 includes the piezoelectric material 202 and a liquid chamber 204; the spray driving device 10 includes a driving circuit 102 and a control circuit 104 And a feedback circuit 106; the feedback circuit 106 includes a voltage detection sub-circuit 10602 and a current detection sub-circuit 10604.

[0077] The spray module 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com