Adjusting method and structure for resonance frequency of demounting type spray head of atomizer

A technology of resonance frequency and adjustment method, applied in the direction of the atomizer for treatment, etc., can solve the problems of difficult cleaning, blockage of the spray head, and the need to adjust the working frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

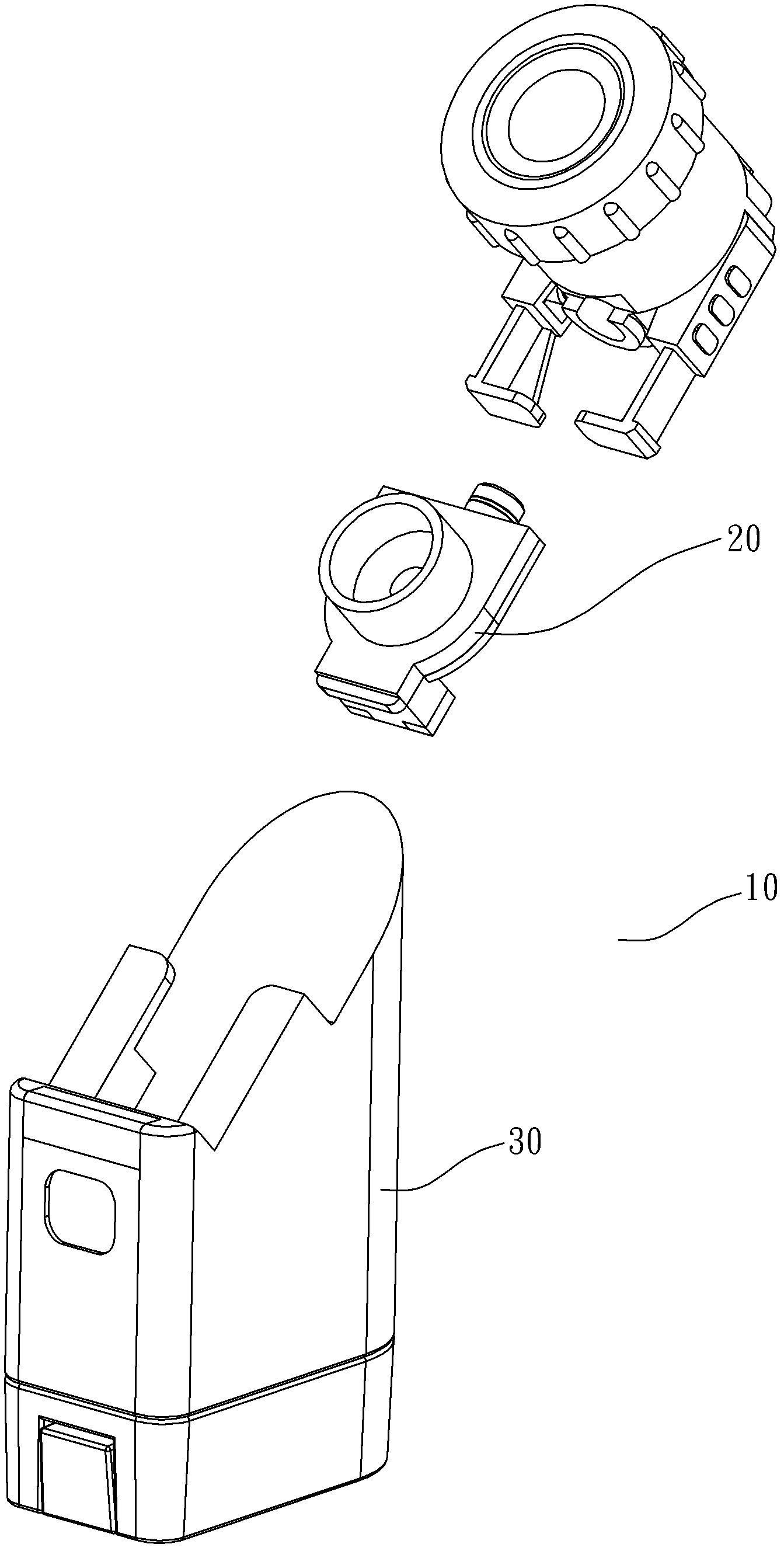

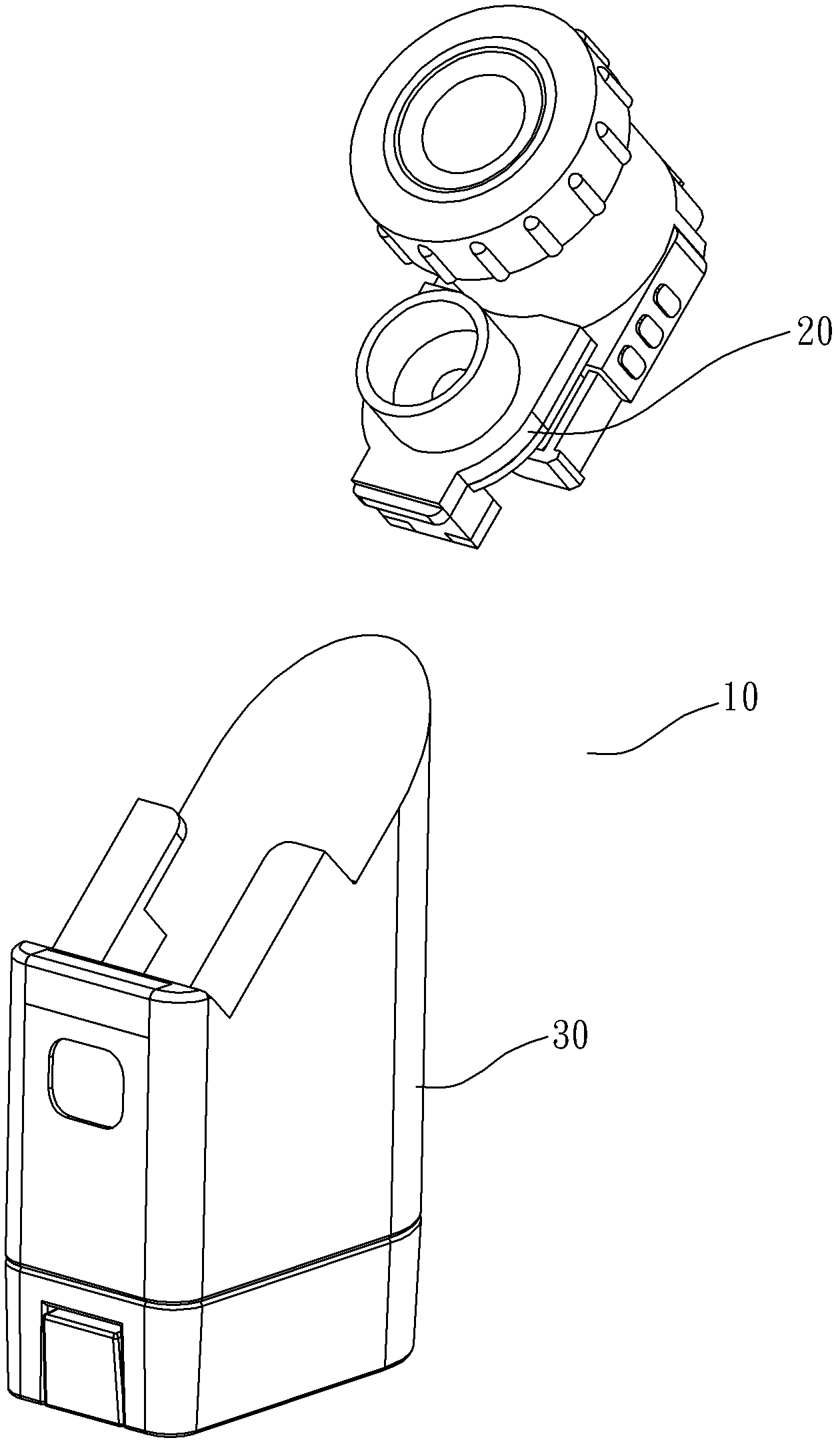

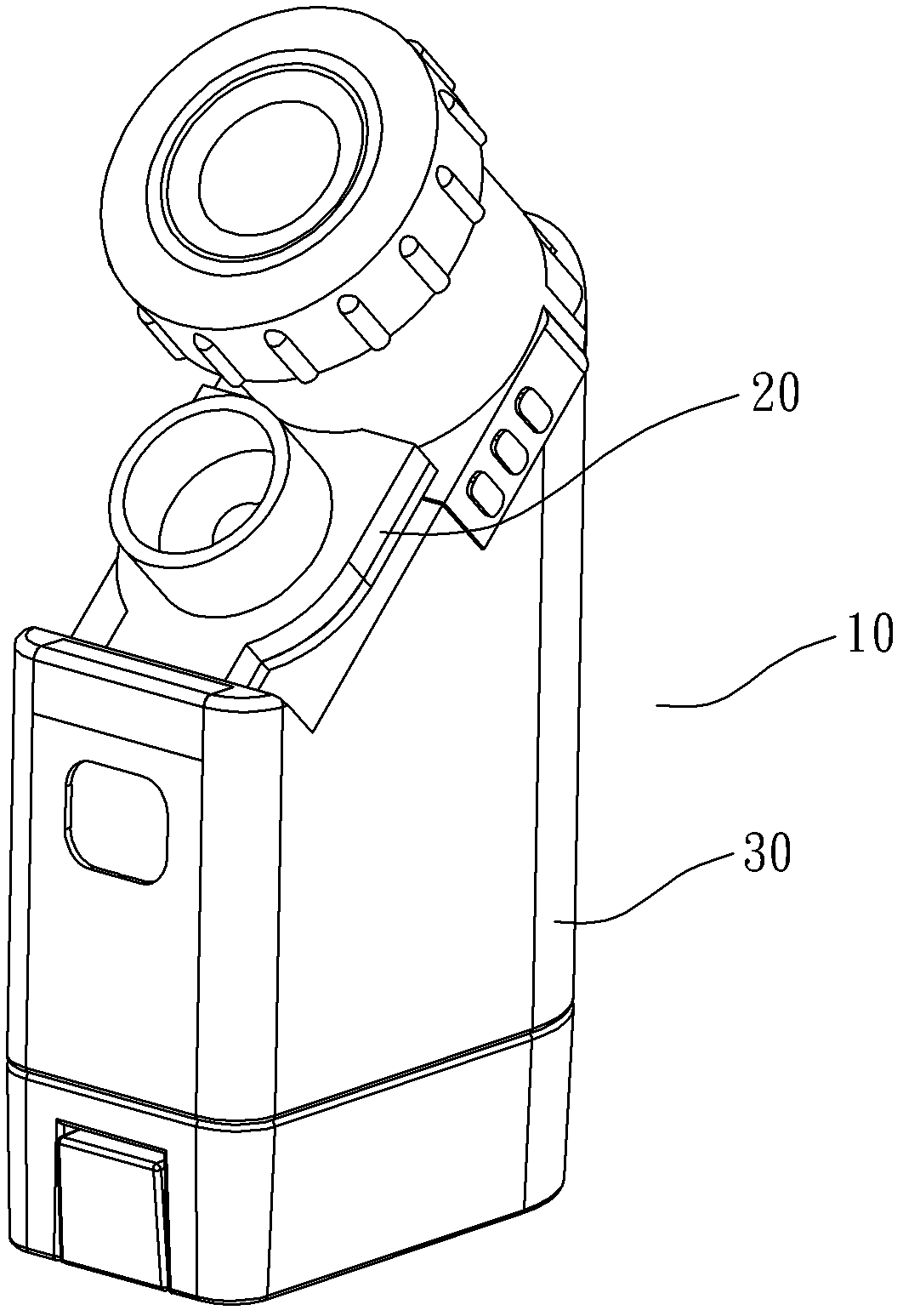

[0022] A method for adjusting the resonant frequency of a detachable spray head of an atomizer, such as figure 1 , 2 , 3, 4, and 5 are when the detachable spray head 20 of the atomizer 10 is assembled on the host 30 or when the electrical connection is completed, the microcomputer 31 (Micro Controller Unit, MCU) in the host 30 will gradually send a The preset frequency and more than one detection frequency are successively amplified by the signal of the power amplifying unit 32 to detectably drive the piezoelectric element 21 on the spray head 20 to work; There is a resistor R on the connection line, and a feedback signal generating unit 40 (which can be a voltage signal processor) is used to detect the change of the electrical (current) signal at both ends of the resistor R, and the frequency and detection are preset by the microcomputer 31. The sending of the frequency generates an initial value feedback signal and more than one modulation value feedback signal one by one t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com