Resonant Thin Film Layers, Resonators and Filters

A thin film layer and resonator technology, applied in impedance networks, electrical components, etc., can solve the problems of a single resonator frequency and the inability to meet the needs of resonator operating frequency diversity, and achieve the effect of enriching diversity and enriching design methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present application will be described below in conjunction with the drawings in the embodiments of the present application. In the description of the present application, the terms "first", "second", etc. are only used to distinguish descriptions, and cannot be understood as indicating or implying relative importance.

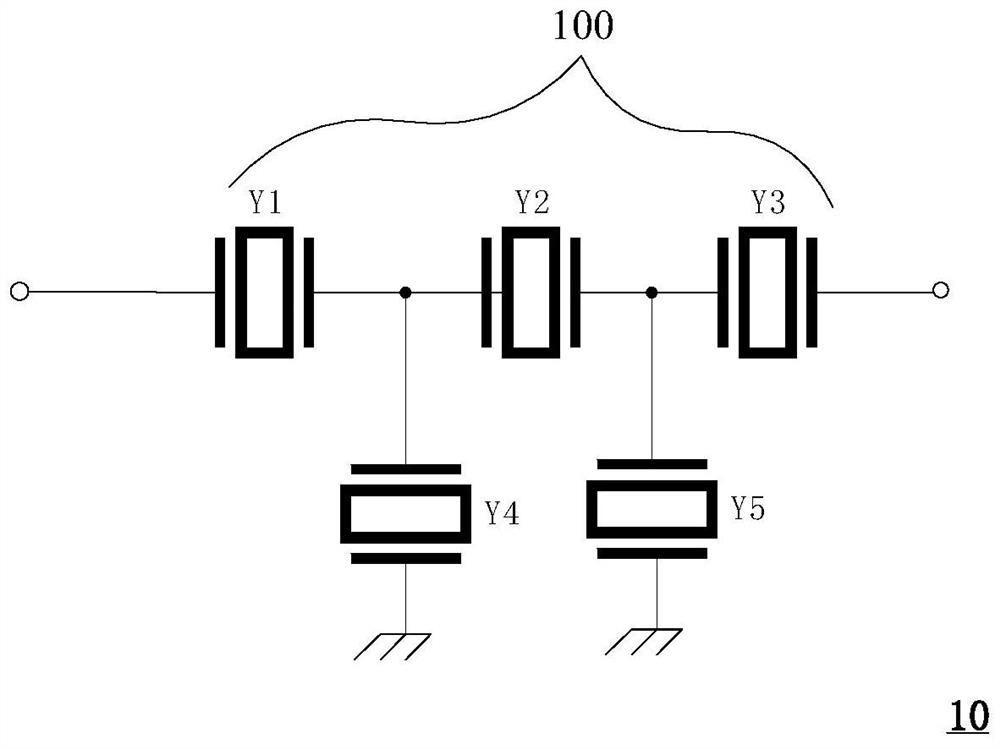

[0031] Please see Figure 1A , which is a schematic diagram of a filter 10 in an embodiment of the present application. The filter 10 in this embodiment includes: a plurality of first resonators, and a plurality of first resonators are connected in series at the input and output ends of the filter 10, such as Figure 1A Resonator Y1, resonator Y2 and resonator Y3 are shown as the first resonator.

[0032] A plurality of second resonators each connected between a node and a common terminal of the two first resonators. Figure 1A The resonator Y4 and the resonator Y5 shown are the second resonators, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com