Coaxial adjustment device and coaxial adjustment method using the same

An adjustment device, coaxial technology, which is applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve problems such as coaxial adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

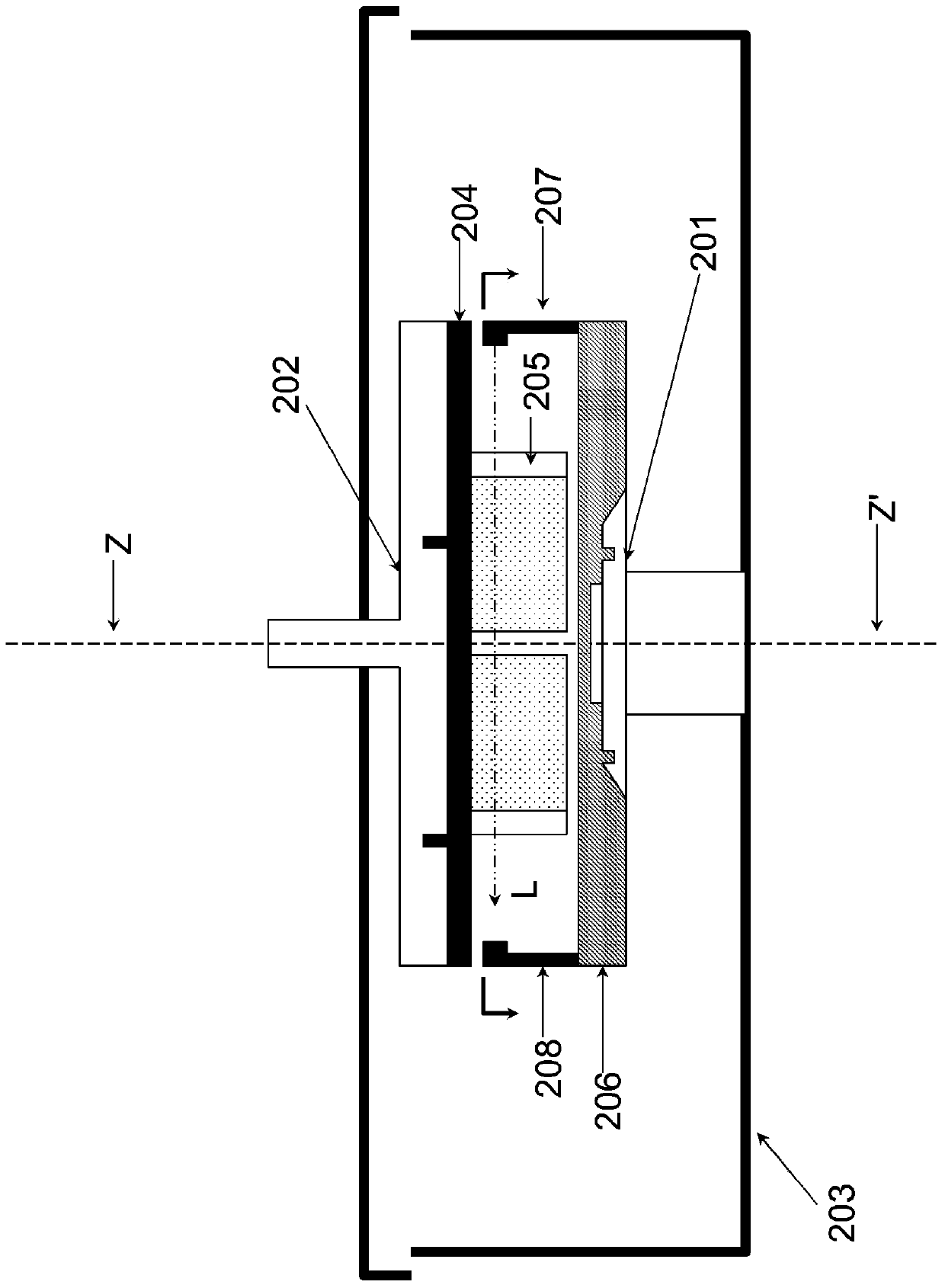

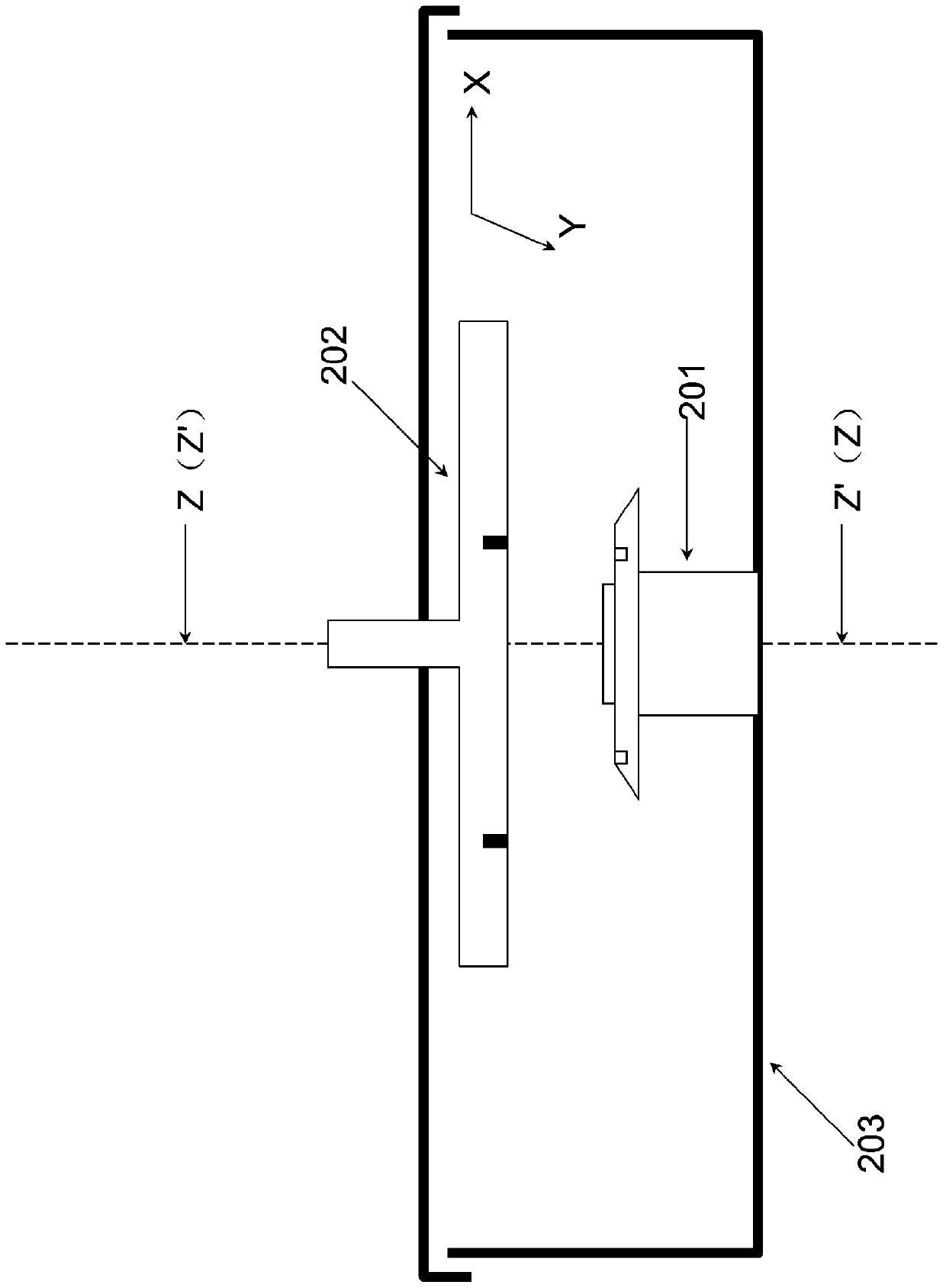

[0061] A method for coaxially adjusting wafer fixation 202 and showerhead 201 using the coaxial adjustment device of Embodiment 1, comprising steps:

[0062] Install the positioning plate 204 on the wafer fixing plate 202 according to the manner determined by the positioning hole 209 and the positioning pile 212;

[0063] Install the positioning seat 206 on the nozzle 201 according to the manner determined by the first set of mounting holes 210 and the positioning column 215;

[0064] Turn on the laser device, and emit the laser beam directionally from the transmitting part 207 of the laser device to the receiving part 208;

[0065] Adjust the horizontal position and the vertical position of the wafer fixing plate 202 so that the laser beam falls into the shielding area of the shield 205 and directly strikes the shield 205 along a direction parallel to the X axis; the wafer fixing plate 202 is controlled to drive the positioning plate 204 Translate along the Y-axis until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com