Laser

A technology of lasers and laser sources, applied in the direction of lasers, laser components, phonon exciters, etc., can solve problems such as out-of-focus, affecting operation accuracy, affecting operation power and operation quality, and solve coaxial problems and improve operation Effects on precision and quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

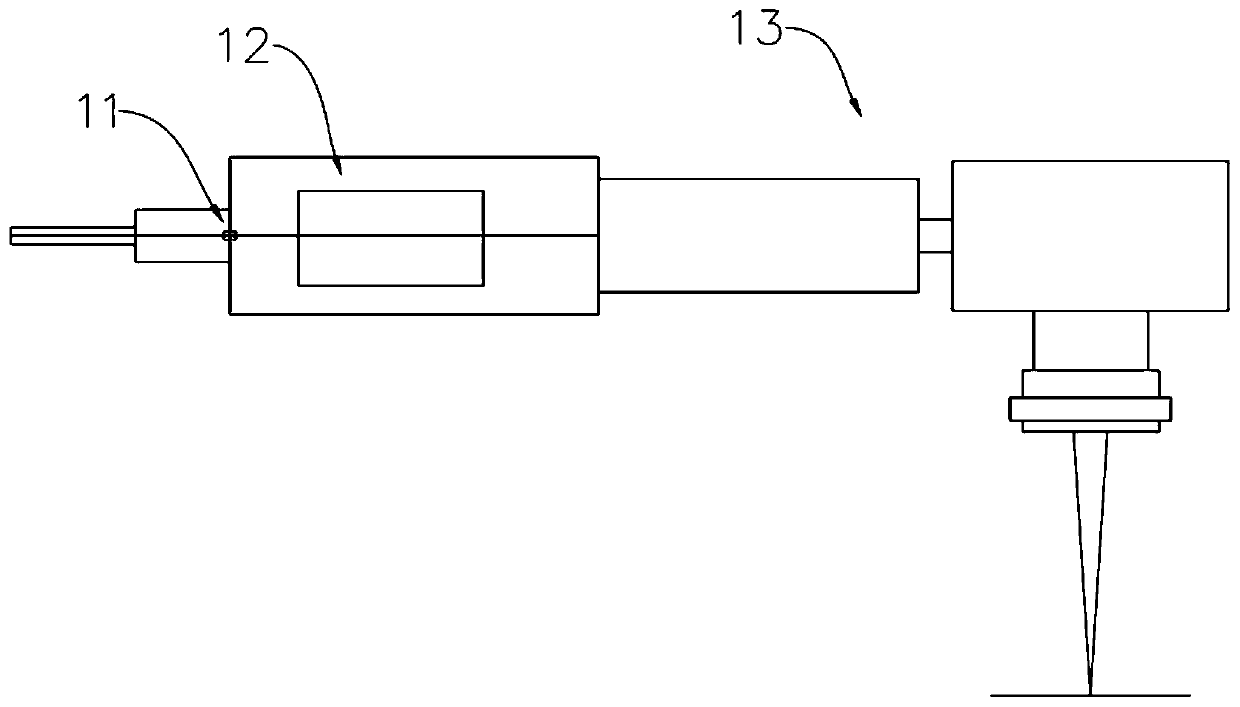

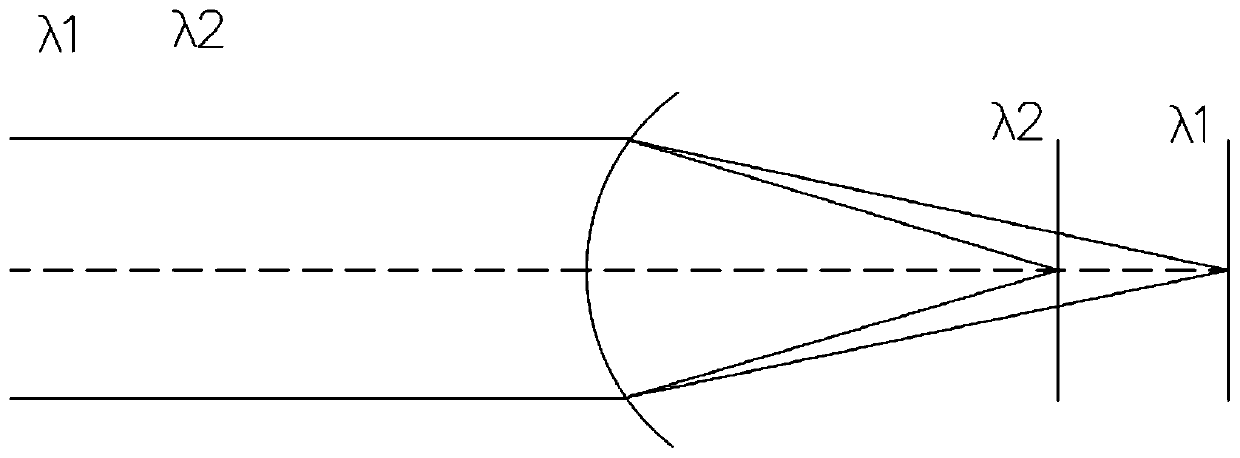

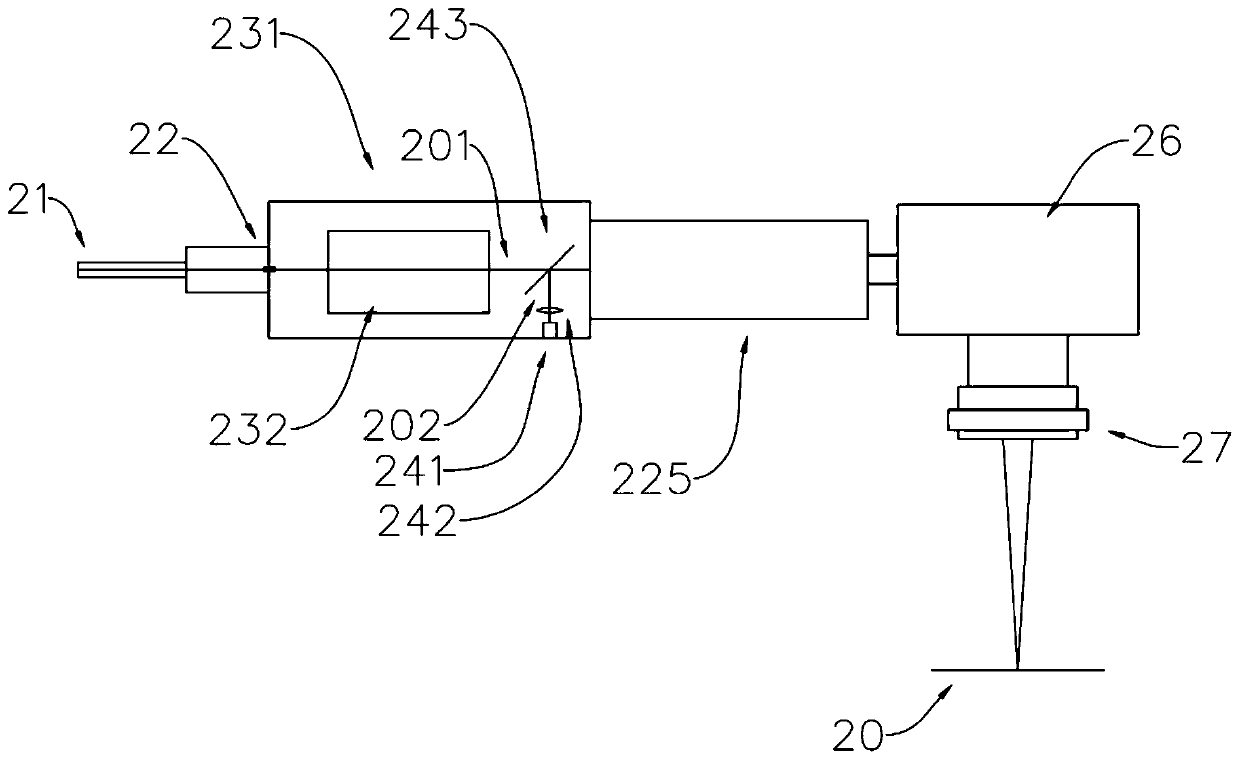

[0027] refer to image 3 and Figure 4 , the laser is sequentially provided with a laser source (not shown), a collimator 22, an isolator 232 and an optical lens assembly along the output main optical path, the laser source is connected with the collimator 22 through an optical fiber 21, and the output collimation The laser, in this embodiment the laser uses the laser 201 with a wavelength λ1 of 1064nm, which is invisible light. The optical lens assembly includes a beam expander 225, a vibrating mirror 26 and a field lens 27 arranged in sequence along the output main optical path, the beam expander 225 is located at the rear stage of the dichromatic sheet 243, the vibrating mirror 26 is located at the rear stage of the beam expander 225, and the field lens 27 is located at the rear stage of the vibrating mirror 26 . The laser output from the laser source passes through the collimator 22 , the isolator 232 , the beam expander 225 , the vibrating mirror 26 and the field lens 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com