Tobacco material classifying device and method

A technology of tobacco material and classification equipment, applied in the fields of tobacco, tobacco preparation, food science, etc., can solve the problems of low separation efficiency, inability to separate filamentous cut stems and flaky cut stems, and large differences, so as to overcome the relatively high shredding efficiency. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

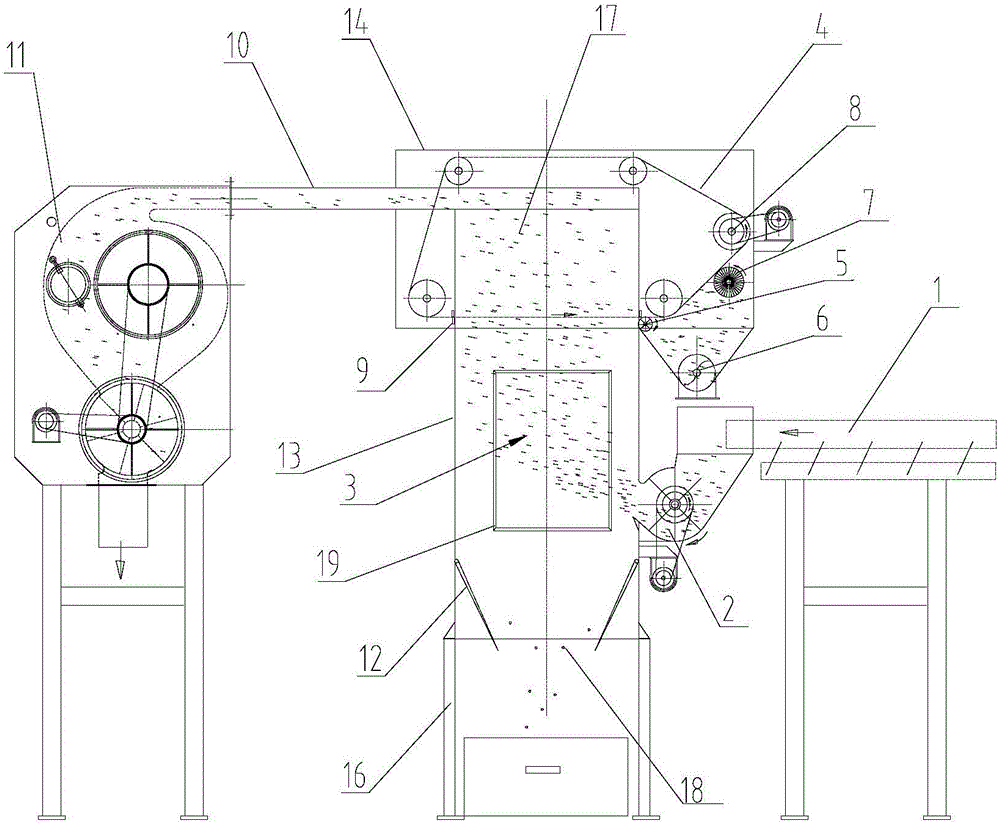

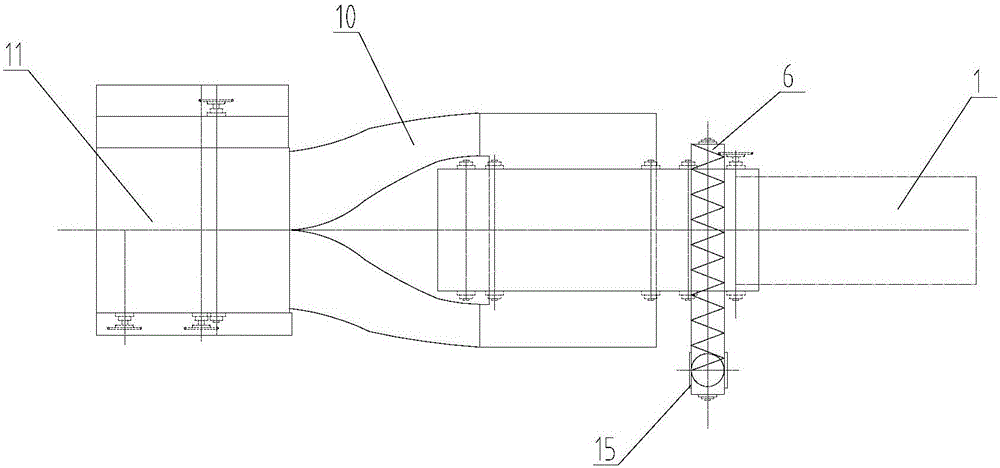

[0031] Such as figure 1 , 2 Shown, the present invention comprises winnowing box body 13, tangential blanking device 11, material throwing roller 2, vibrating conveyor 1, sub-screen belt 4, frame 16. The winnowing box body 13 is installed on the frame 16, and is divided into a collection area 17, a filtering area, a winnowing area 3 and a miscellaneous material area 18 for filamentous stems and wind from top to bottom; , Offer the observation window 19 on the winnowing box body 13, can check the winnowing situation of winnowing area through the watch window 19. The winnowing box body 13 is welded by wallboards, and the size of the rectangular dimension of its inner cavity is related to production capacity. The outlet of the vibrating conveyor 1 is connected to the feed port of the throwing roller 2, and the throwing roller 2 is installed at the inlet end of the air separation box body 13, and the throwing roller 2 throws the material to the air selection area 3, and the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com