Oil seal removal tools and usage methods

A technology for dismantling tools and oil seals. It is applied in the manufacture of tools and hand-held tools. It can solve problems such as scratches, damaged parts, and time-consuming and laborious disassembly of oil seals. It achieves the effects of protecting the working surface, uniform force, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 A special removal tool for oil seal

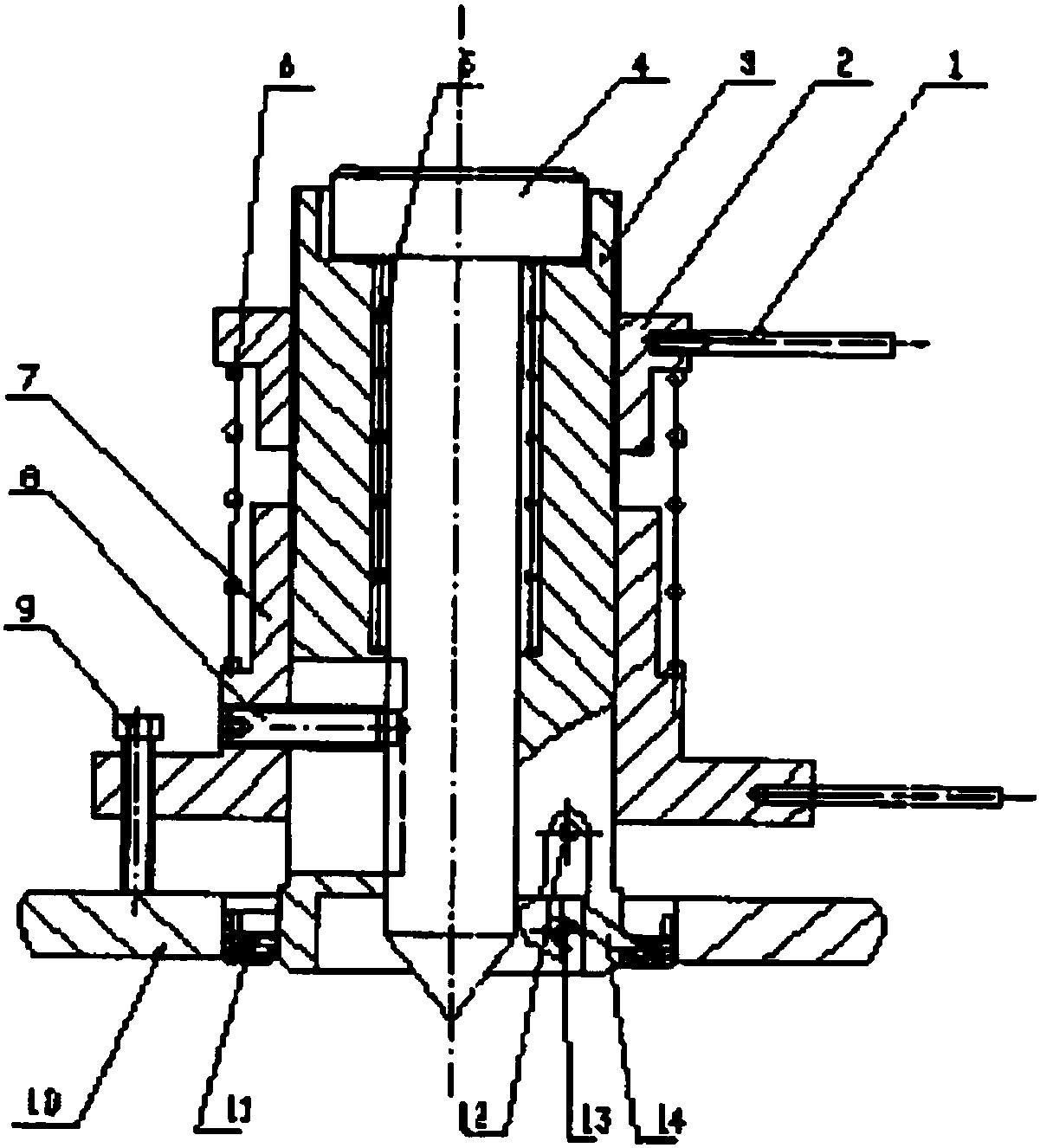

[0034] Such as figure 1 As shown, the oil seal removal tool is composed of adjusting nut 2, mandrel 3, push rod 4, compression spring I5, compression spring II6, positioning sleeve 7, limit screw 8, adjustment screw 9 and the removal device.

[0035] The adjusting nut 2 is installed on the mandrel 3 .

[0036] Described mandrel 3 is shaped on step hole and keyway 1.

[0037] Described push rod 4 is packed in the stepped hole of mandrel, and the front end of push rod 4 is made into conical part.

[0038] Described stage clip I5 is packed in the stepped hole, and is arranged between mandrel 3 and push rod 4.

[0039] The compression spring II6 is installed outside the mandrel 3, one end is connected with the adjusting nut 2, and the other end is connected with the positioning sleeve 7.

[0040] The positioning sleeve 7 is made into a step shaft with a through hole, which is set on the mandrel 3. A limit screw 8 is ins...

Embodiment 2

[0046] Embodiment 2 The method of using the special removal tool for oil seal

[0047] Using the special oil seal removal tool in Example 1, the method of removing the oil seal downward is as follows:

[0048] 1) Measure the depth of the oil seal to be disassembled into the workpiece;

[0049] 2) Adjust the adjusting screw and adjusting nut according to the measured size;

[0050] 3) Put the mandrel of the oil seal removal tool into the aperture of the oil seal to be removed, so that the front end of the shift fork just corresponds to the notch of the oil seal to be removed;

[0051] 4) In the initial state, under the action of compression spring I, one end of the push rod extends out of the mandrel, and the shift fork is retracted inward under the action of the coil spring. Downward displacement, the conical part of the front end of the push rod touches the shift fork, the shift fork overcomes the force of the coil spring, opens outwards and extends into the oil seal slot, ...

Embodiment 3

[0054] Embodiment 3 The method of using the special removal tool for oil seal

[0055] Using the special tool for removing the oil seal in Example 1, the method of pulling out the oil seal upwards is as follows:

[0056] 1) Measure the depth of the oil seal to be disassembled into the workpiece;

[0057] 2) Adjust the adjusting screw and adjusting nut according to the measured size;

[0058] 3) Put the mandrel of the special removal tool for the oil seal into the aperture of the oil seal, so that the front end of the shift fork just corresponds to the notch of the oil seal;

[0059] 4) In the initial state, under the action of the pressure spring I, one end of the push rod extends out of the mandrel, and the shift fork is in the state of retracting inward under the action of the coil spring, and an external force is applied to the push rod downward. Displacement, the conical part of the front end of the push rod touches the shift fork, and the shift fork overcomes the force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com