Slag blocking ball for converter

A technology of slag blocking ball and converter, which is applied in the field of iron and steel metallurgy, can solve the problems of reducing the amount of slag, the high cost of equipment installation and maintenance, and the installation of complex equipment, so as to eliminate the phenomenon of stranding, increase the success rate, and reduce the amount of slag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

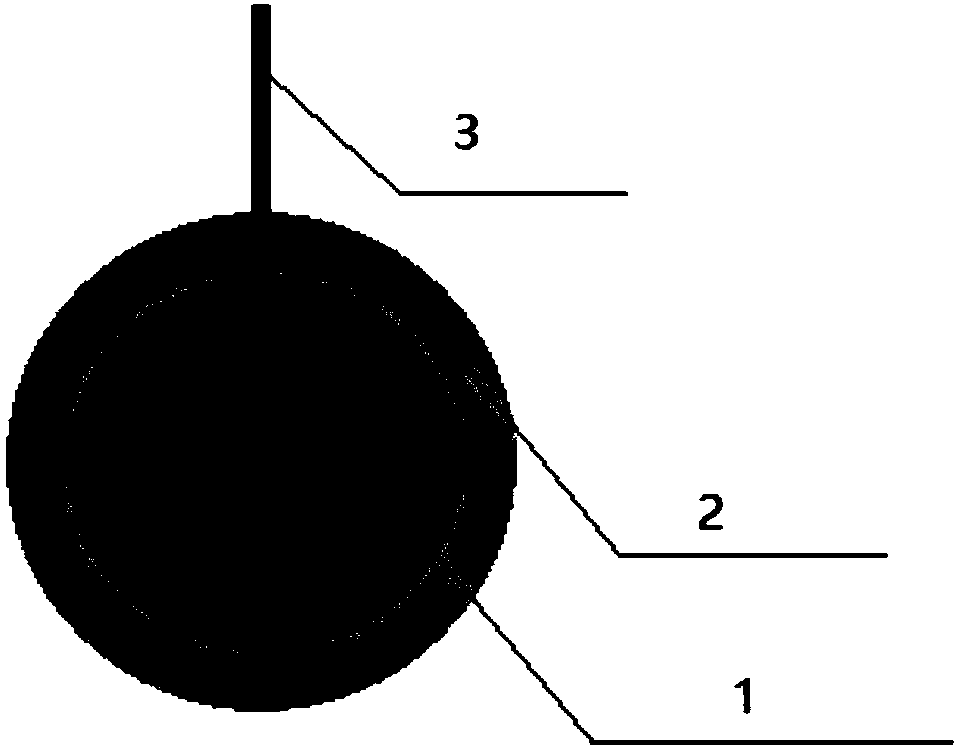

[0025] like figure 1 Shown is a slag blocking ball for a converter. The slag blocking ball includes a ball base 1 and a handle 3 connected to the ball base. The surface of the ball base 1 is coated with a gas generating layer 2 with a thickness of 1-50 cm.

[0026] A circle of gas generating material is coated on the surface of the ball matrix to form a gas generating layer, and the gas generating layer is made of CaCO 3 , MgCO 3 、BaCO 3 1. Calcium aluminate cement is mixed and coated according to the proportion of 30%:30%:30%:10%. The diameter of the ball base is 30cm, and the thickness of the gas generating material is 10cm. The slag blocking ball is used in conjunction with the sliding plate slag blocking technology to block slag. When the tapping end is critical for 1 minute, the slag blocking small ball of the present invention is thrown into the vicinity of the tapping hole by the slag blocking trolley. Under high temperature conditions, the slag blocking The ball pro...

Embodiment 2

[0028] like figure 1 Shown is a slag blocking ball for a converter. The slag blocking ball includes a ball base 1 and a handle 3 connected to the ball base. The surface of the ball base 1 is coated with a gas generating layer 2 with a thickness of 1-50 cm.

[0029] A circle of gas generating material is coated on the surface of the ball matrix to form a gas generating layer, and the gas generating layer is made of CaCO 3 , MgCO 3 、BaCO 3 , Aluminate silicate cement is mixed and coated according to the proportion of 30%:40%:20%:10%, the diameter of the ball base is 35cm, and the thickness of the gas generating material is 15cm. Utilize the slag blocking ball of the present invention to block slag, and when the tapping criticality ends for 1 minute, use the slag blocking trolley to throw the slag blocking ball into the vicinity of the tapping hole, and in a high temperature state, gas is generated, which has the effect of suppressing the eddy current Function, the generated g...

Embodiment 3

[0031] like figure 1 Shown is a slag blocking ball for a converter. The slag blocking ball includes a ball base 1 and a handle 3 connected to the ball base. The surface of the ball base 1 is coated with a gas generating layer 2 with a thickness of 1-50 cm.

[0032] A circle of gas generating material is coated on the surface of the ball matrix to form a gas generating layer, and the gas generating layer is made of CaCO 3 , MgCO 3 、BaCO 3 , Aluminate silicate cement is mixed and coated according to the proportion of 40%:40%:10%:10%, the diameter of the ball base is 40cm, and the thickness of the gas generating material is 20cm. Utilize the slag blocking ball of the present invention to block slag, and when the tapping criticality ends for 1 minute, use the slag blocking trolley to throw the slag blocking ball into the vicinity of the tapping hole, and in a high temperature state, gas is generated, which has the effect of suppressing the eddy current Function, the generated g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com