Construction method for covering foundation bed with geotechnical cloth to prevent back silting

A construction method and covering soil technology, applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve problems such as incomplete removal of silt deposits, restrictions on the construction of the next process, and inability to completely remove silt, etc., to achieve anti-silt The effect is obvious, the effect of reducing back-silting deposits, and the construction is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

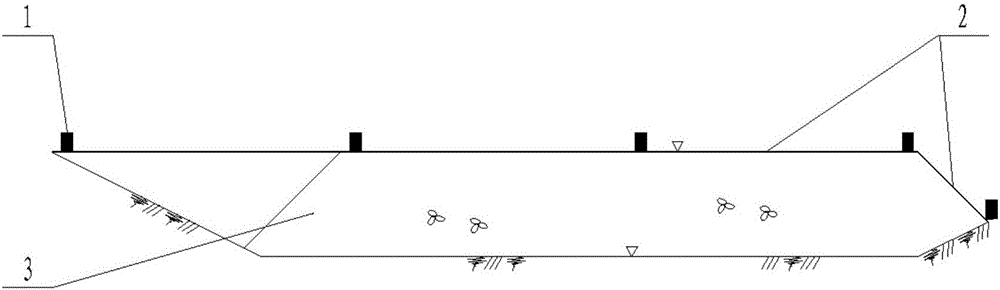

[0016] Take the 250-meter bedding of 205# and 206# general-purpose berths in Xianrendao Port Area of Yingkou Port as an example to describe this method in detail.

[0017] A construction method for covering a foundation bed with a geotextile to prevent back-silting, the steps of which are:

[0018] (1) Foundation bed covered with geotextile: the top of the foundation bed with a length of 100 meters and a width of 30 meters is covered with 1 to 2 layers of geotextiles at the 205# berth in Xianrendao port area;

[0019] (2) Sand bag pressing: Press a row of sand bags every 10 meters around the geotextile to prevent the geotextile from drifting;

[0020] (3) Dredging treatment of the subgrade bed before fine leveling: in March of the second year, the subgrade bed should be desilted before the subgrade leveling. The nylon rope is tied, and the nylon rope is fixed on the square barge. The square barge is used to stir the anchor cable and move the ship to slowly drag the geotexti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com