Cloth wall connecting assembly

A technology for connecting components and connectors, which is applied in the field of background walls, can solve the problems of background cloth wall construction, disassembly and storage difficulty, and achieve the effect of saving time and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

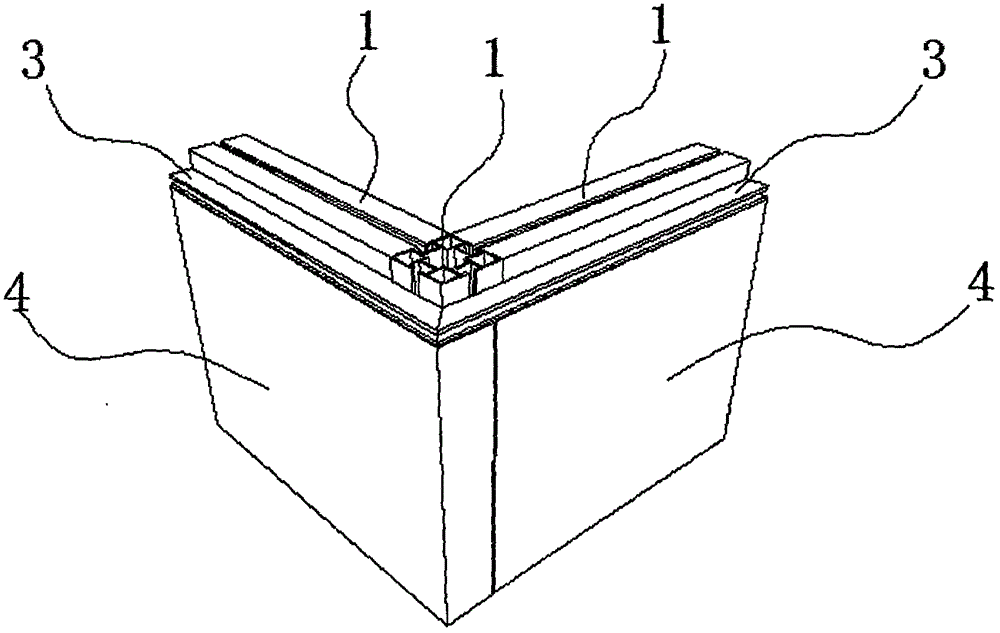

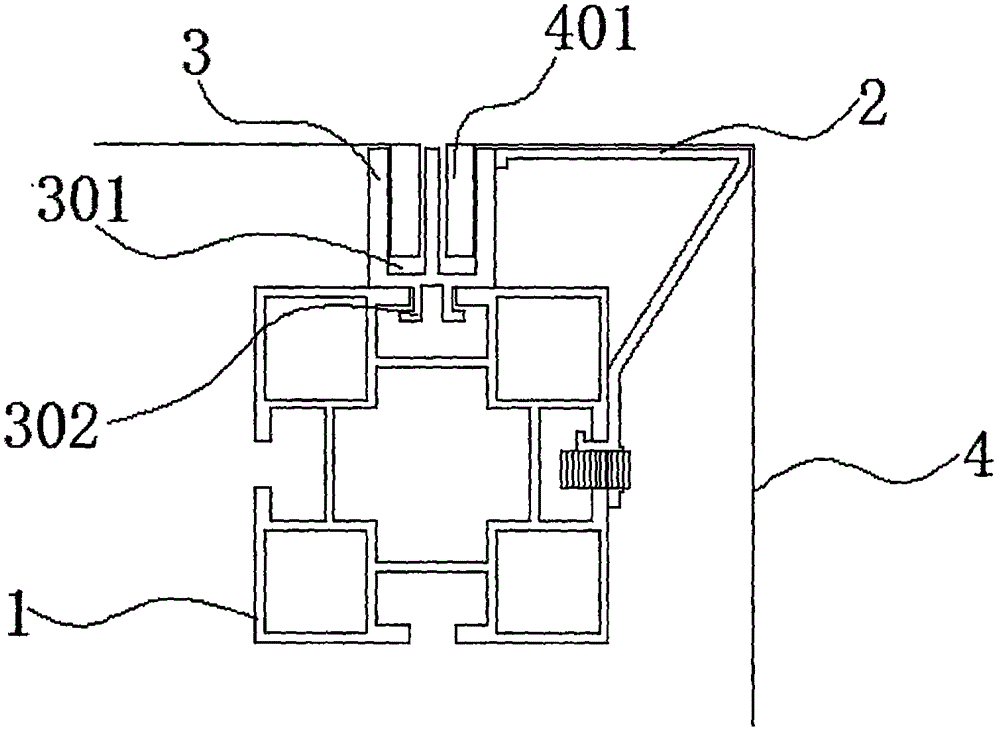

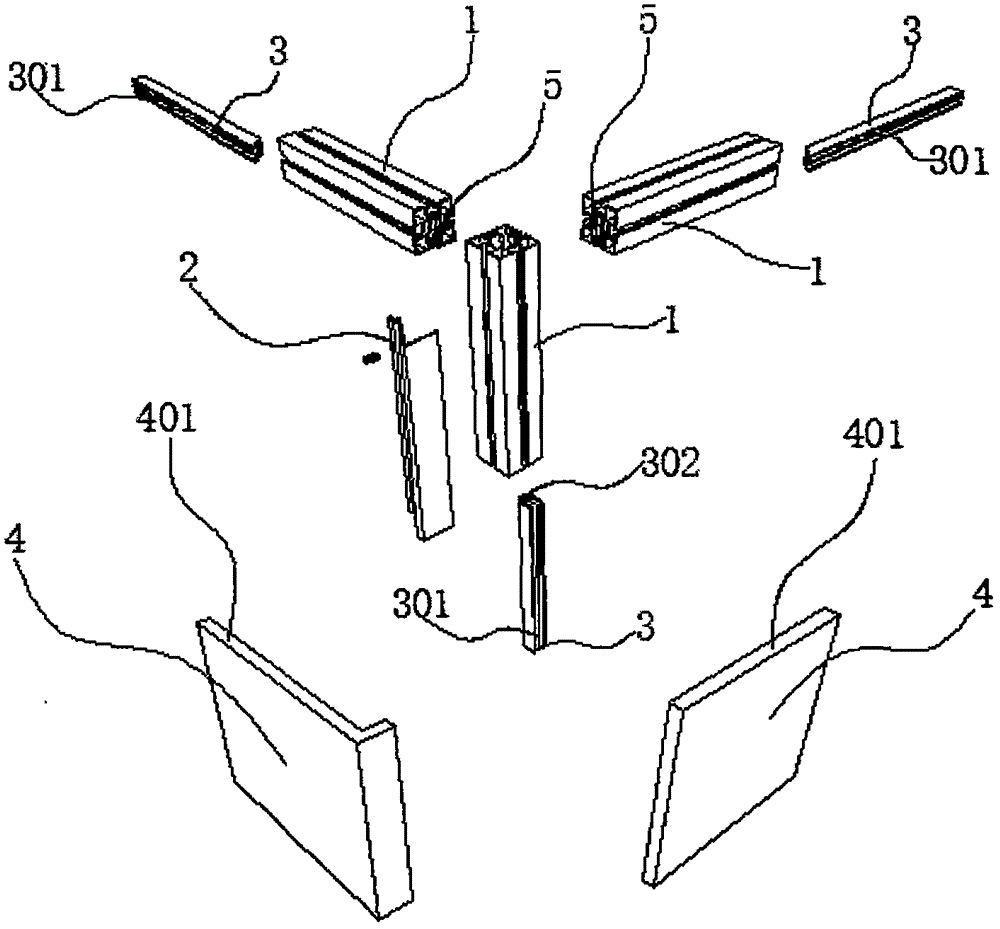

[0015] A cloth wall 4 connection assembly, including a micro-slit aluminum alloy groove connector 3, an aluminum alloy four-way straight rod 1, an aluminum alloy corner straight rod 2, a latch 5 and a cloth wall 4, the micro-slit aluminum alloy groove connector 3 is buckled and connected to one side of the aluminum alloy four-way straight rod 1, the cross-section of the micro-slit aluminum alloy groove connector 3 is E-shaped, and the rear of the micro-slit aluminum alloy groove connector 3 The end face is integrally formed with a "several"-shaped buckle 302, and the front end of the micro-slit aluminum alloy groove connector 3 is provided with two installation grooves 301; the aluminum alloy corner straight rod 2 is fixed by screwing On the other side of the aluminum alloy four-way straight rod 1 adjacent to the micro-slit aluminum alloy groove connector 3, a rubber strip 401 is provided on the side of the cloth wall 4, and the cloth wall 4 The rubber strip 401 is clamped wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap