Method for determining temperature-dependent performance of a friction clutch

A friction clutch, dual clutch technology, applied in the application of friction clutches, clutches, thermometers, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

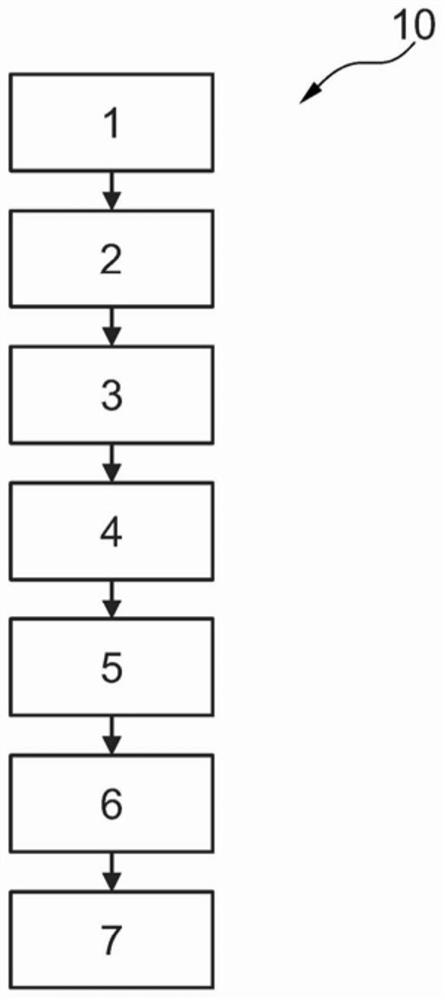

[0023] figure 1 The block diagram of Figure 10 shows the flow of the proposed method. In step 1, the clutch temperature is determined. The clutch temperature can be measured by means of one or more possibly present temperature sensors or can be modeled from it. Alternatively, the clutch temperature can be estimated by means of a temperature model without the aid of a clutch temperature sensor. For this purpose, other operating parameters can be processed, such as the friction torque introduced into the friction clutch, the thermal capacity of the friction clutch, the current coefficient of friction, the temperature around the clutch housing in which the friction clutch is received, etc. Clutch slip is as determined from input and output speeds and applied torque.

[0024] The determination of the modulus of elasticity of at least one disk of the friction clutch, for example the pressure disk or the counter pressure disk, is carried out in step 2, the friction performance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com