Patents

Literature

55results about How to "OK real time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method employing three-dimensional and two-dimensional digital images

InactiveCN102687177AOK real timeFix security situation2D-image generation3D-image renderingTime informationComputer graphics (images)

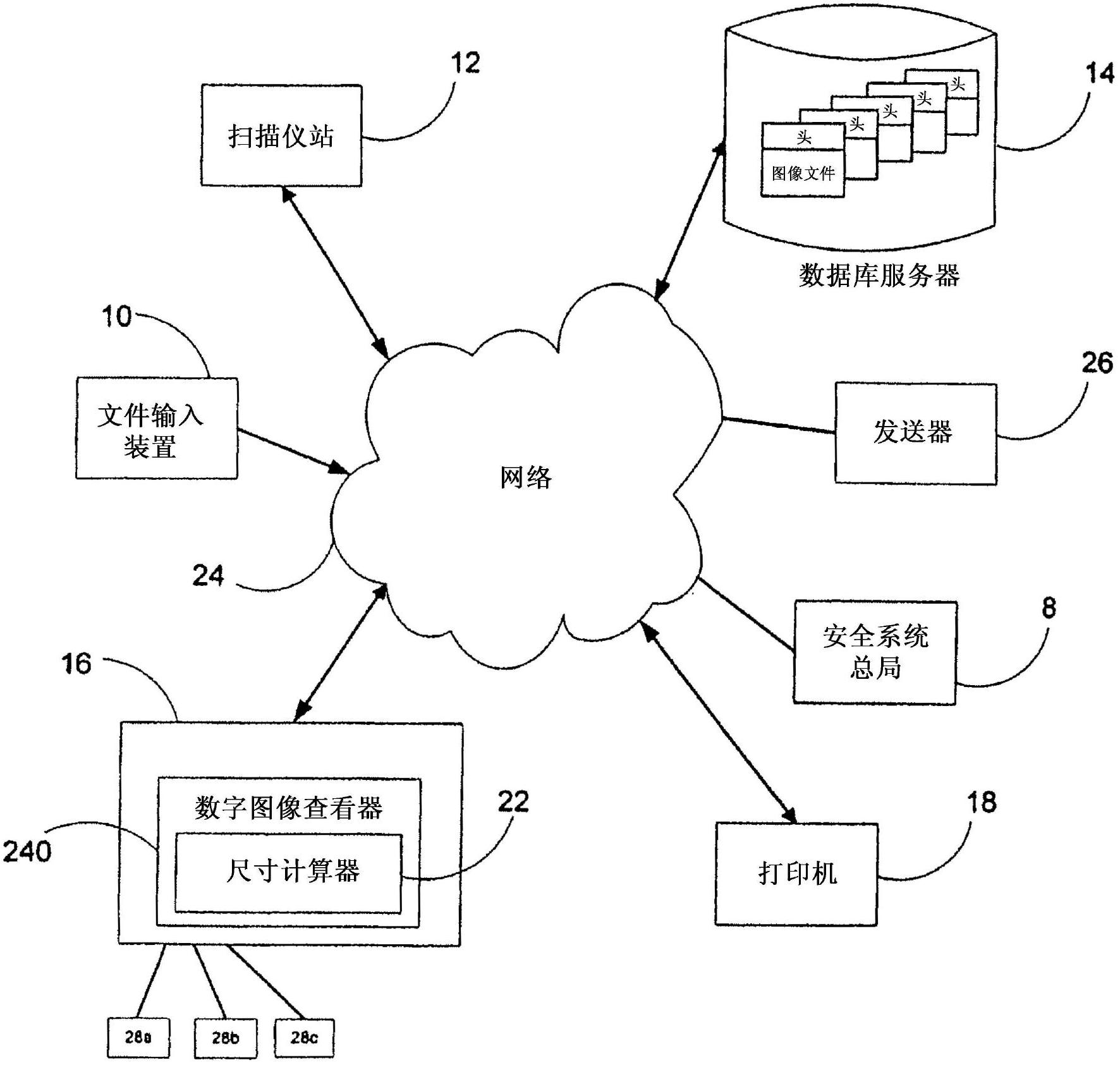

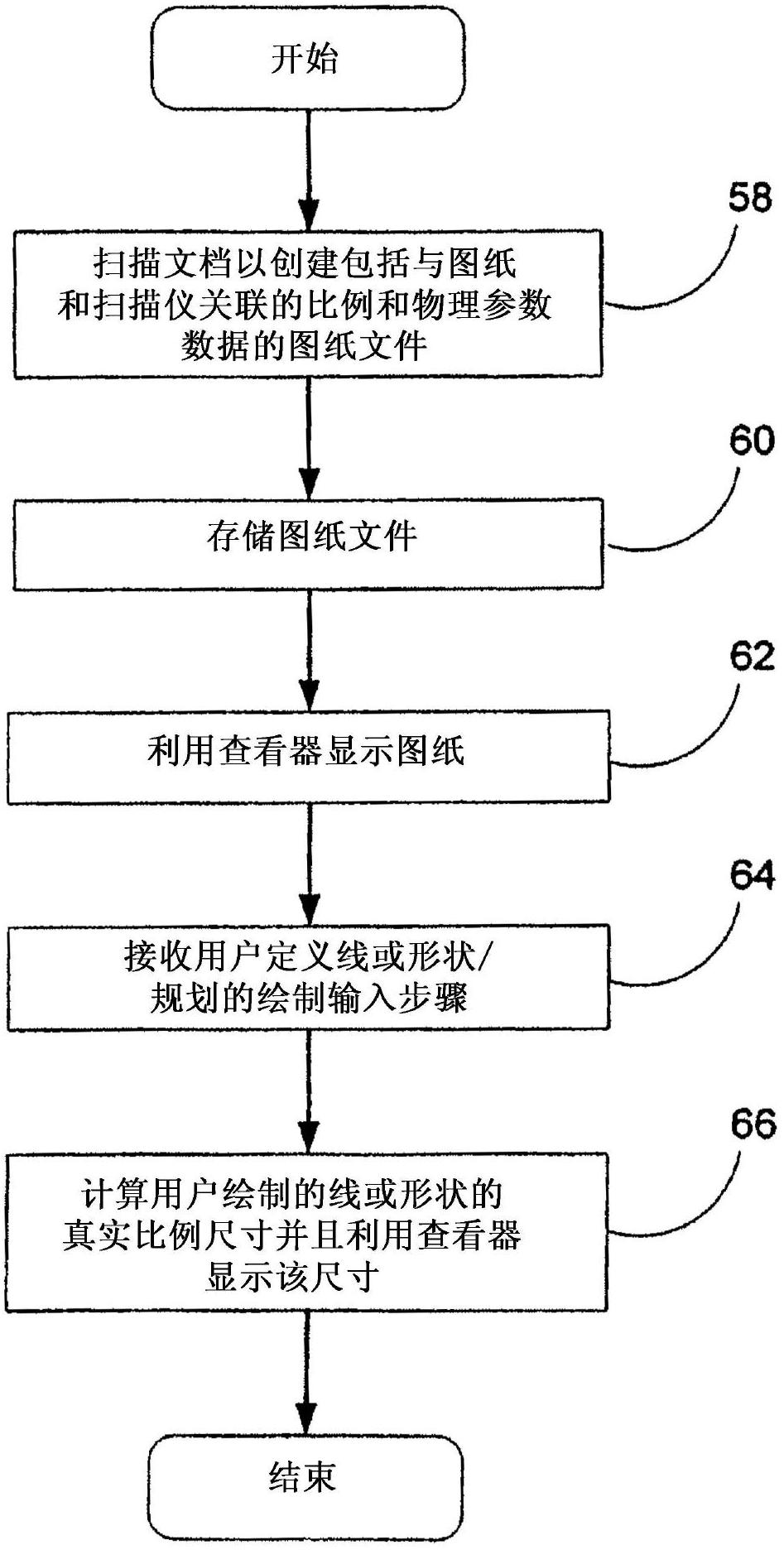

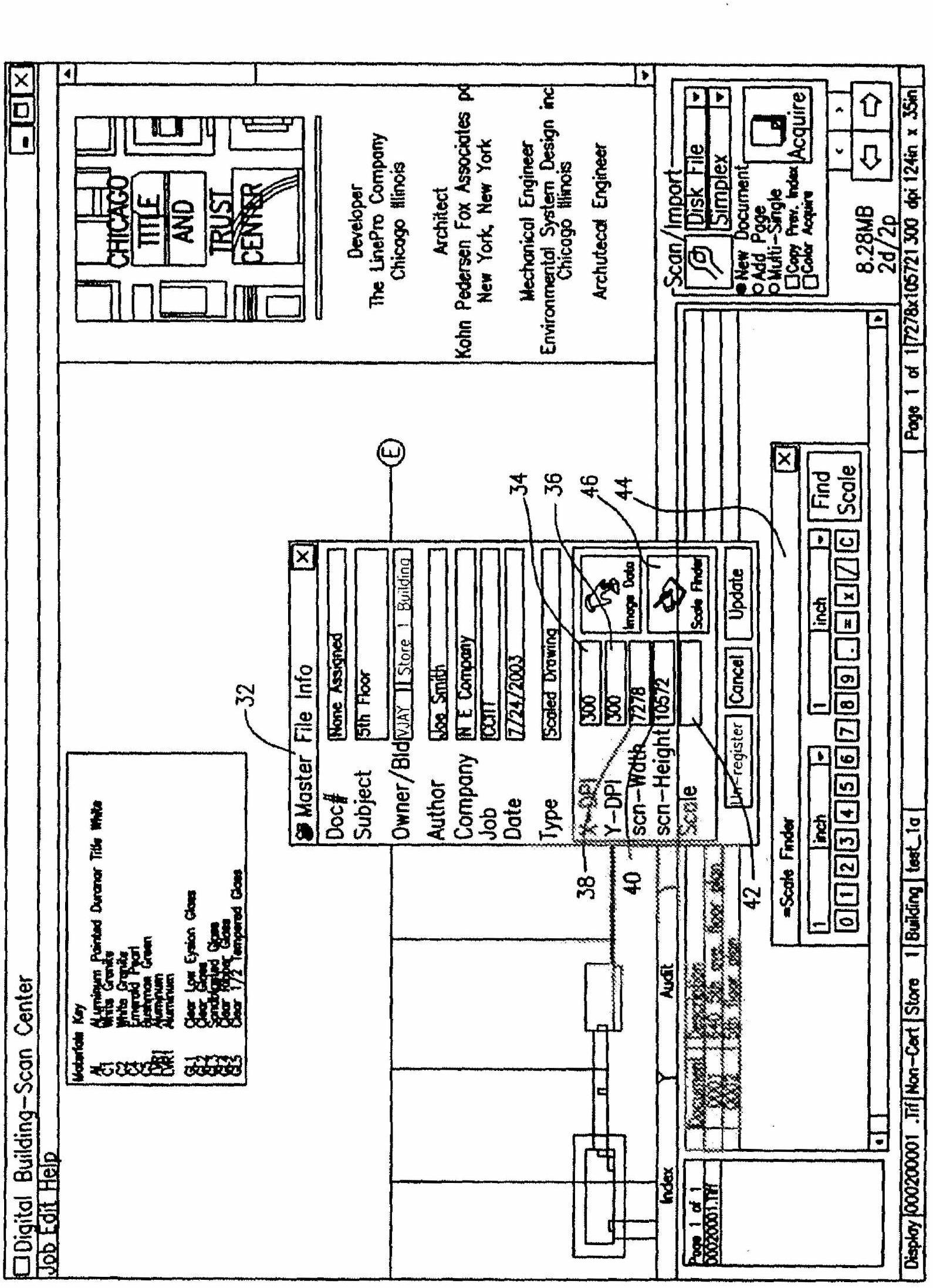

The present invention provides a true-scale, coordinate-matched, linked in real-time, dual three-dimensional / two-dimensional visual display / viewer. The display simultaneously shows a 3D digital image and an associated 2D digital image of a selected drawing. The display of the present invention allows a user to visualize an asset's location, surrounding environment and hazards and true scale structural details for interior or external structural scenes. Using the display and associated tools, the user can obtain real-time information of an environment, true- scale measurement, plan ingress / egress paths, shortest paths between points and the number of doorways in a structure and track objects within the displayed environment. The intelligence gained using the tools and 3D / 2D display may be used and further manipulated by a single user or may be distributed to other users.

Owner:ARCHAIO

Train dispatching optimization method and system

InactiveCN105480263AOK real timeOK automaticallyRailway traffic control systemsRunning timeTime data

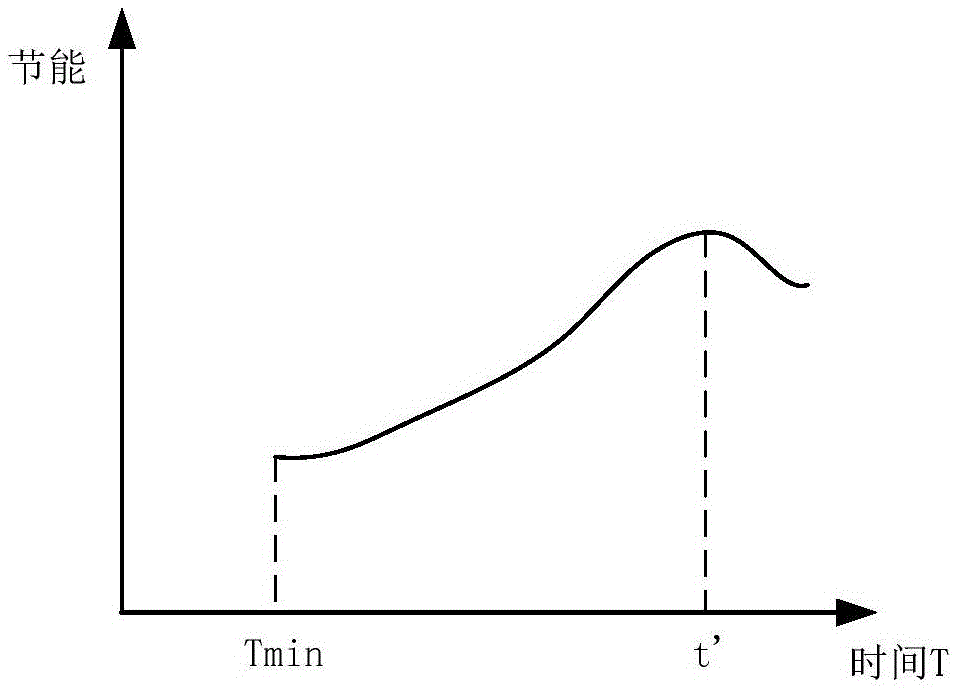

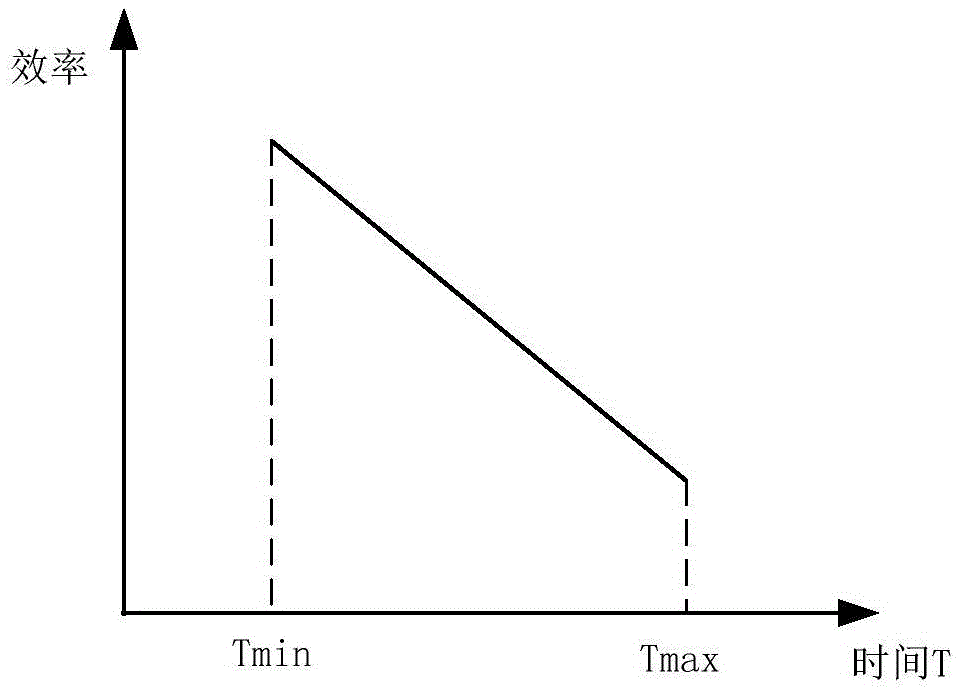

The invention relates to the technical field of railway dispatching and discloses a train dispatching optimization method and system. The method comprises the following steps: when a train leaves a station or passes through a station, acquiring the state information of the next station; acquiring the interval total time data when the train runs to the next station according to the state information of the next station and the state information of the train; and determining the optimal interval running time when the train runs to the next station according to the relation between the interval total time and train dispatching optimization indexes. According to the invention, the optimal train running time can be automatically and accurately determined in real time according to the train dispatching optimization indexes, safe running is ensured, the railway transportation efficiency is greatly improved, and energy sources are saved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

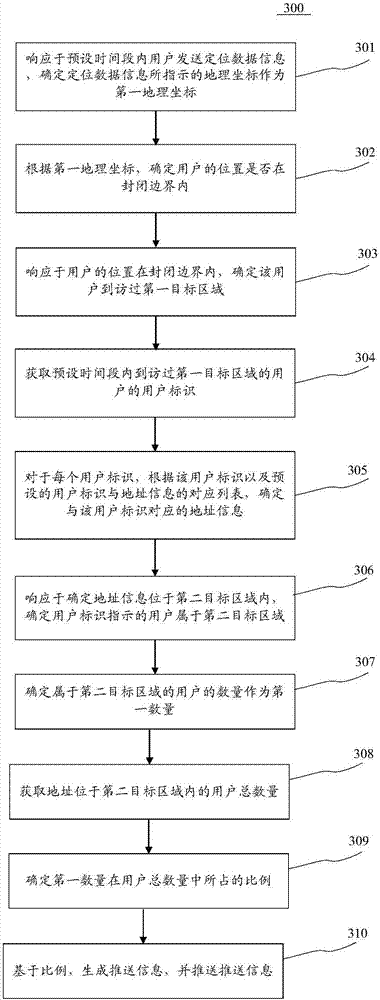

Information pushing method and apparatus thereof

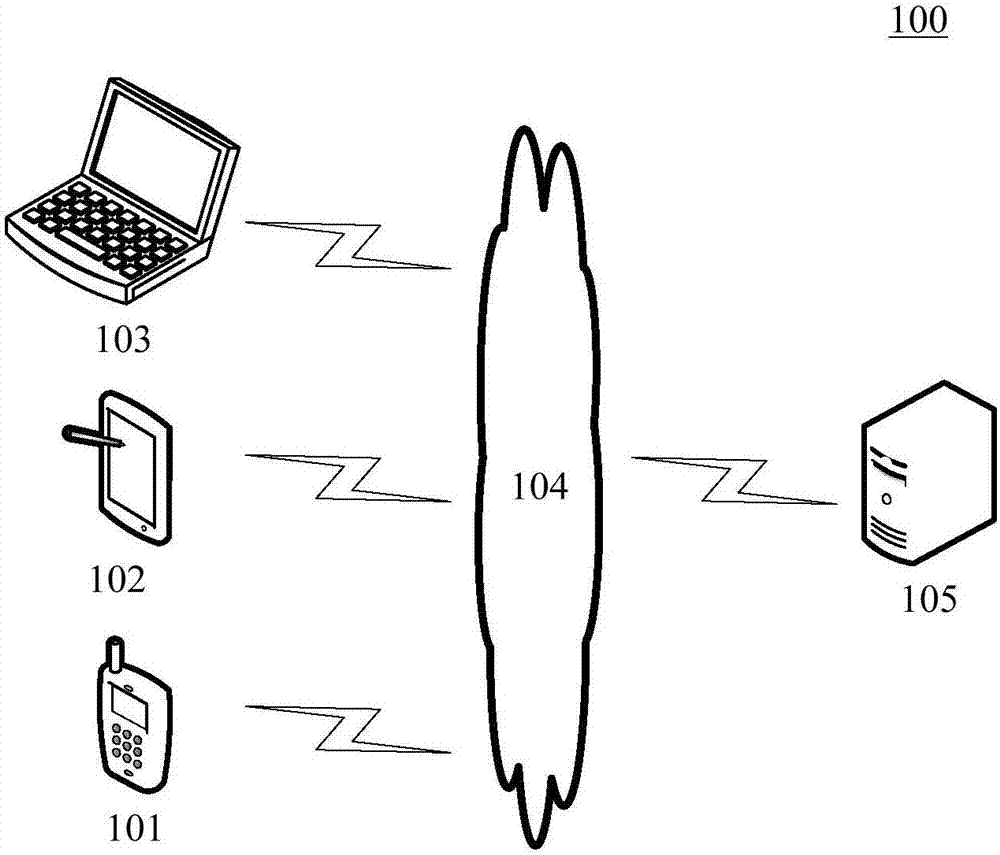

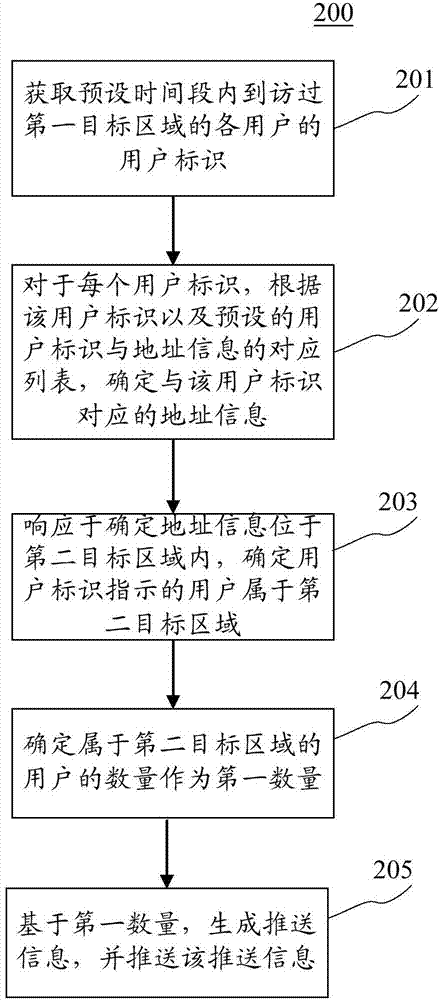

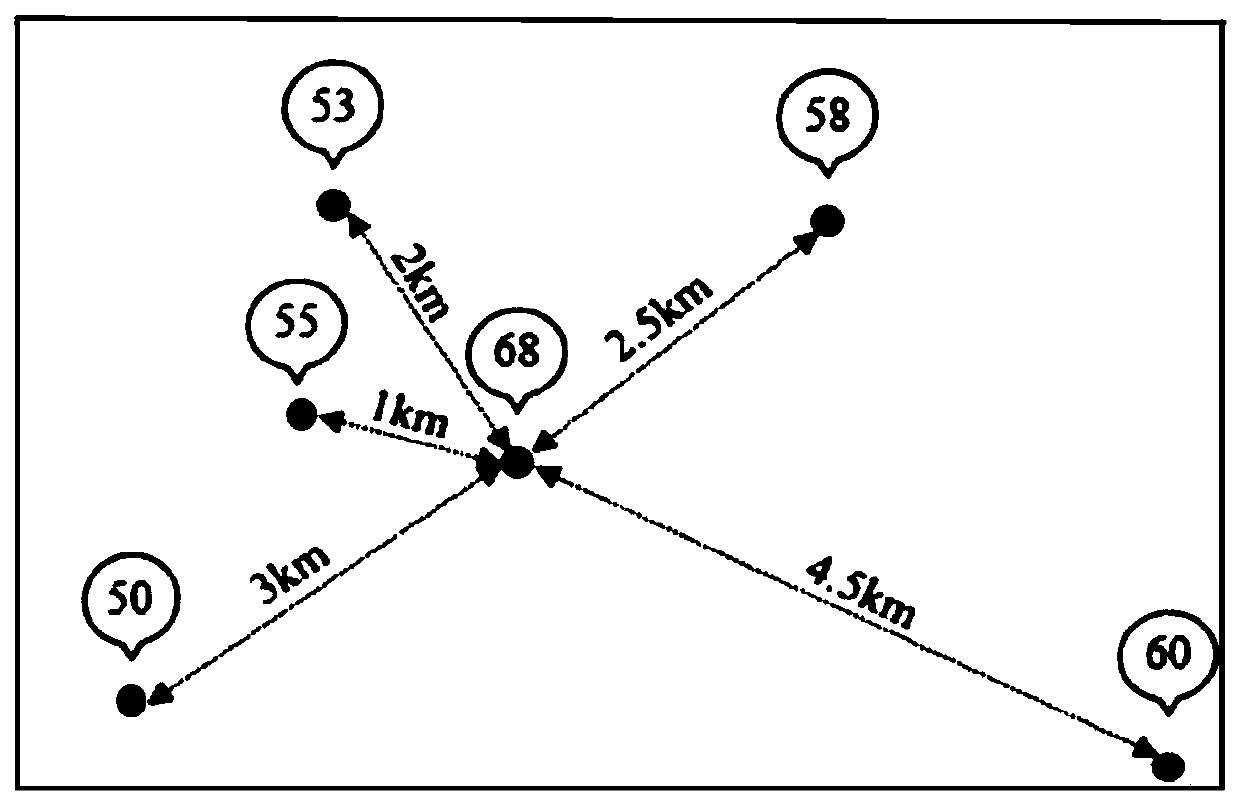

The invention discloses an information pushing method and an apparatus thereof. The method comprises the following steps of acquiring a user identification of each user which visits a first target area in a preset time period; for each user identification, according to the user identification and a corresponding list of a preset user identification and address information, determining the address information corresponding to the user identification; responding to determine that the address information is located in a second target area, and determining that a user indicated by the user identification belongs to the second target area; determining a quantity of the users belonging to the second target area as a first quantity; and based on the first quantity, generating pushing information and pushing the pushing information. By using the method, timeliness of a visitor flow rate state of the first target area can be increased.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

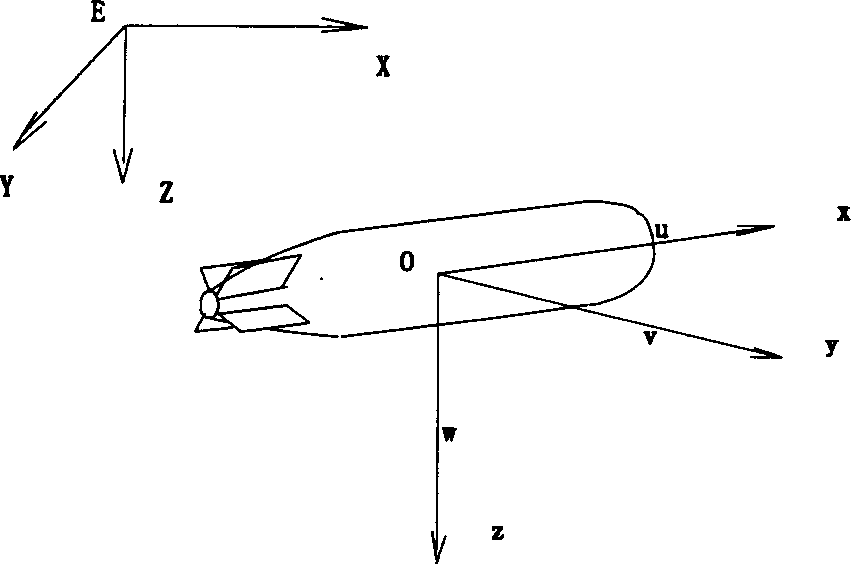

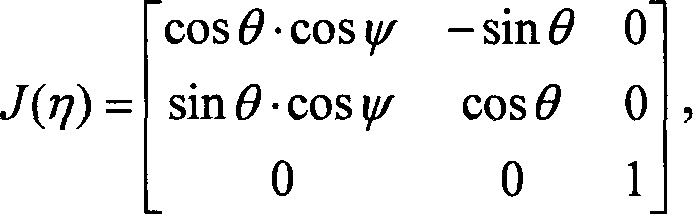

Positioning method for manned submersible without fixed reference point

InactiveCN1779484AAvoid lostAvoid troubleNavigation instrumentsAcoustic wave reradiationInertial coordinate systemPositioning technology

A positioning method in inertial coordinate system of manned submersible with no fixed reference point includes confirming a fixed coordinate first then confirming inertial coordinate at certain time of mother ship and manned submersible, using position at this certain time of manned submersible as initial value to carry out flight trace calculation of manned submersible and then converting each coordinate of manned submersible to be coordinate in inertial coordinate system.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

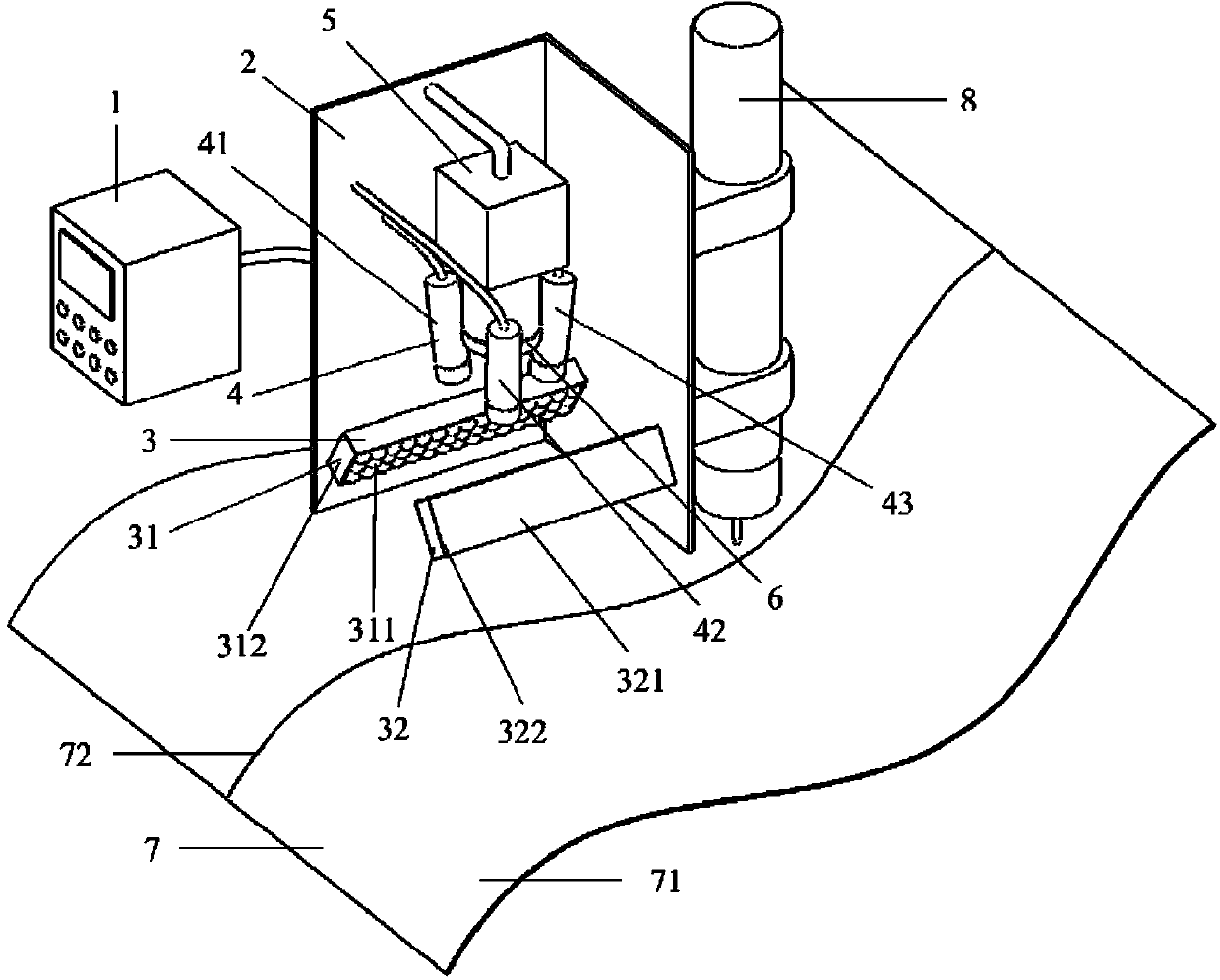

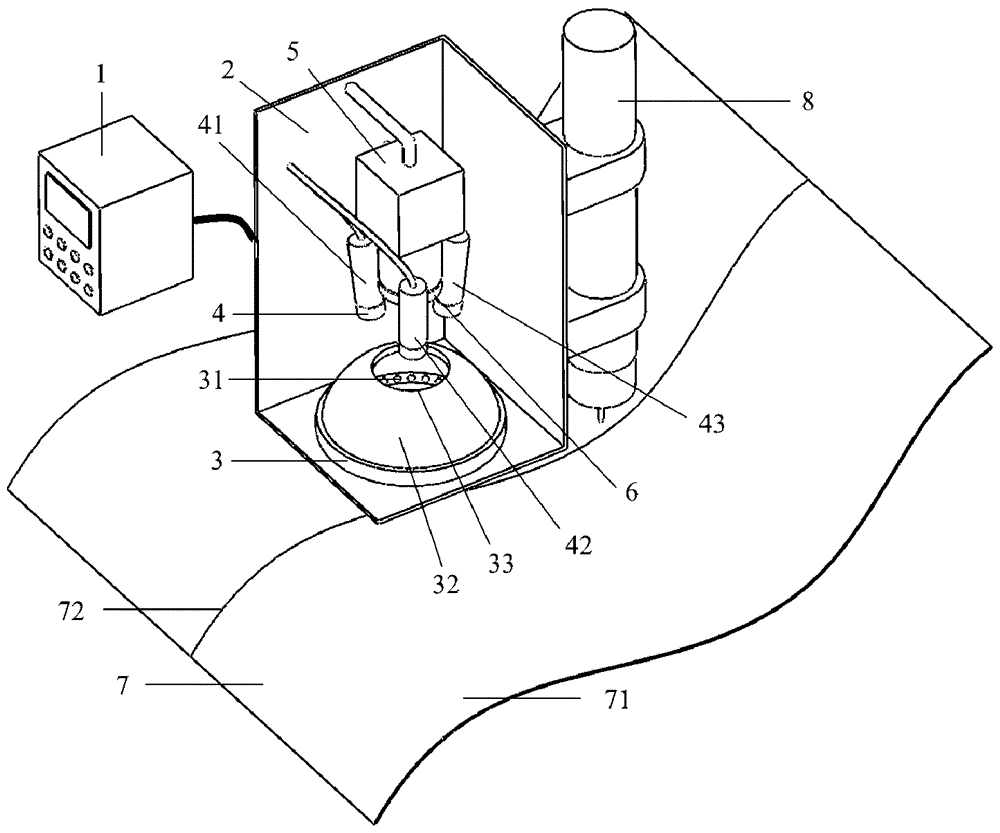

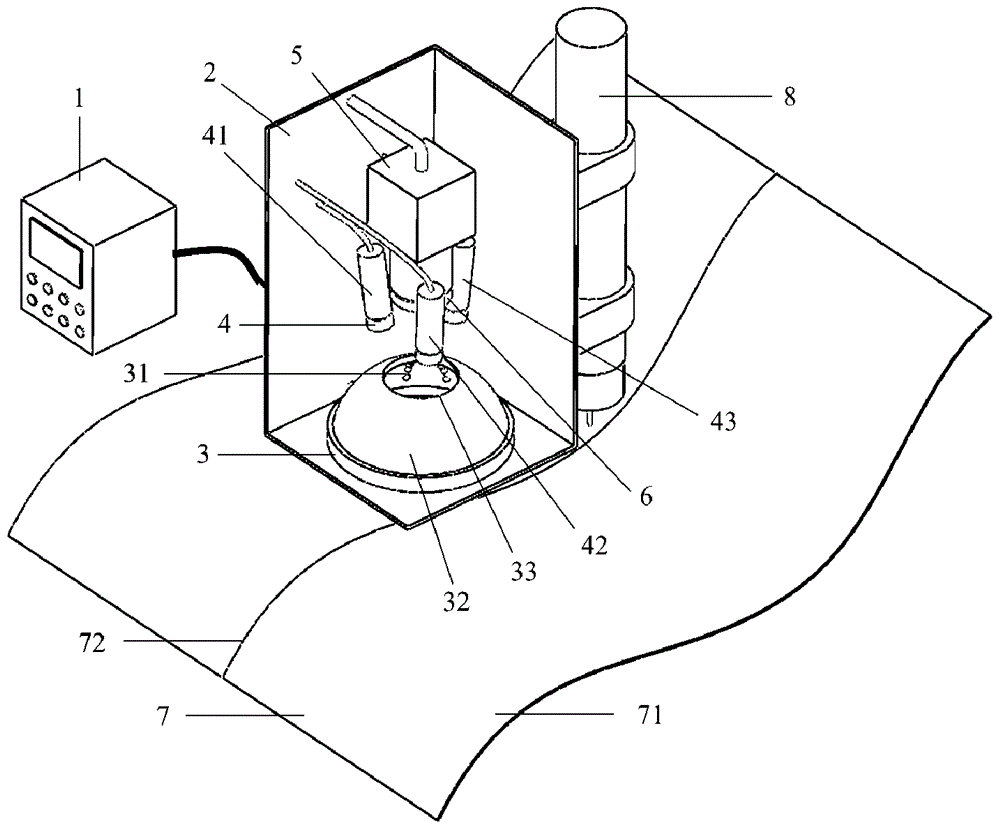

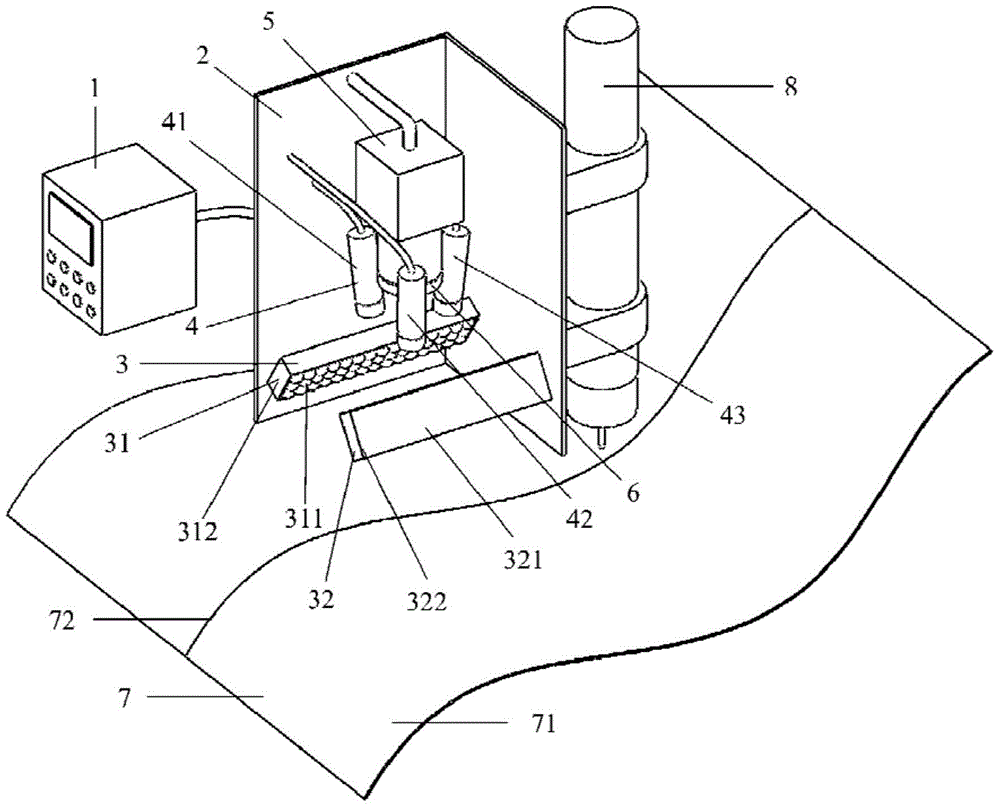

Strong specular reflection workpiece thin and narrow groove detection device and method based on strip-shaped light sources

The invention provides a strong specular reflection workpiece thin and narrow groove detection device and method based on strip-shaped light sources, and belongs to the field of welding automation. According to the device and the method, a strip-shaped light source array irradiates the surface of a workpiece so that a workpiece surface image with the uniform gray level can be obtained, and the automatic detection on a strong specular reflection workpiece thin and narrow groove is achieved by determining the relative position and the posture between a welding gun and the workpiece through a laser array. According to the device and the method, the strip-shaped light source array irradiates the surface of the strong specular reflection workpiece so that the uniform-illumination workpiece surface image can be obtained, the characteristics of the groove in the image are obvious, the center position of the groove is conveniently and accurately extracted, and the detection accuracy can reach 0.03 mm; the relative position and the posture between the workpiece and the welding gun can be rapidly and accurately obtained through the laser array; the system structure is simple, the detection accuracy is high, instantaneity is high, cost is low, and the strong specular reflection workpiece thin and narrow groove detection device and method can be applied to automatic detection of the groove of the strong specular reflection workpiece surface and are particularly suitable for the occasion of high-energy beam welding automatic tracking of the thin and narrow groove workpiece with the groove gap smaller than 0.1 mm.

Owner:TSINGHUA UNIV

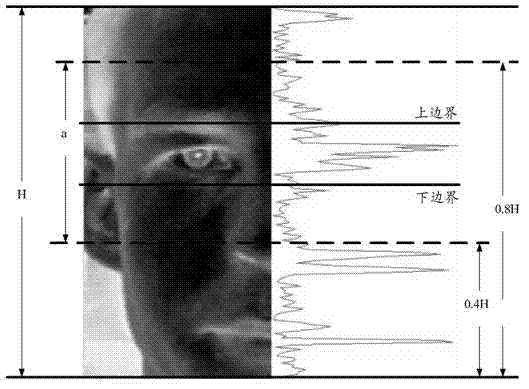

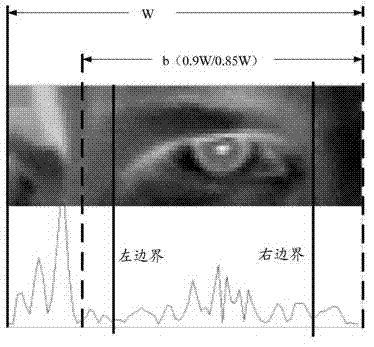

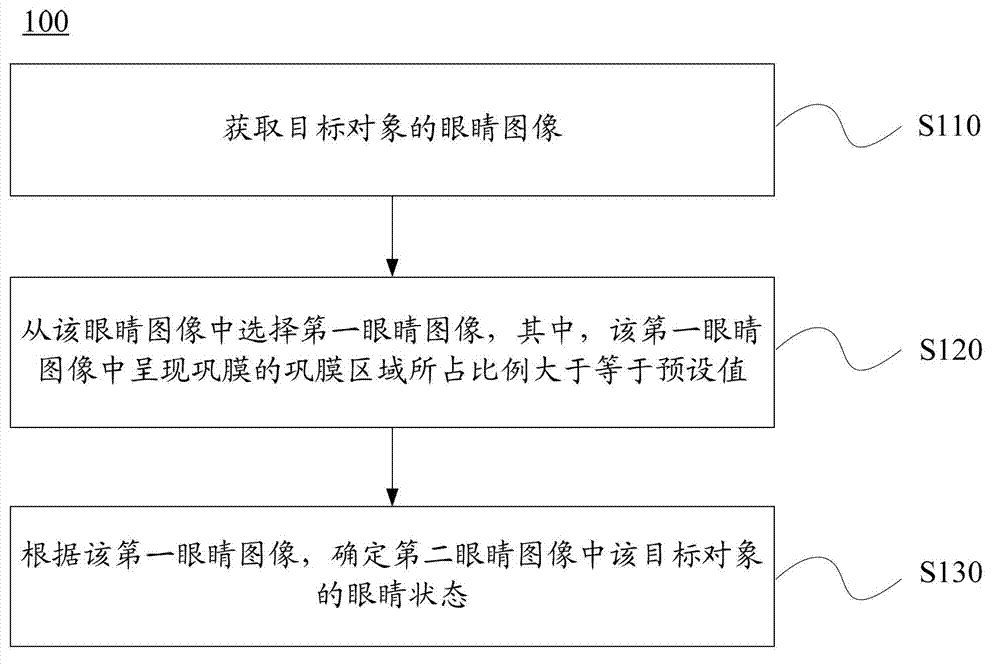

Method and device for determining eye state

InactiveCN102831399AAccurately determineOK real timeCharacter and pattern recognitionComputer science

The embodiment of the invention provides a method for determining an eye state. A template for the eye state can be accurately and rapidly determined in real time, and therefore the eye state is accurately and rapidly determined. The method comprises the steps of: obtaining an eye image of a target object; selecting a first eye image from the eye image, wherein the proportion of a sclera region in the first eye image showing sclera is more than or equal to a preset value; and determining the eye state of the target object in the second eye image according to the first eye image. According to the method and the device for determining the eye state, provided by the embodiment of the invention, the eye opening template is determined according to the proportion of the sclera region in the eye image showing the sclera, and can be accurately and rapidly determined in real time, thus the eye state can be accurately and rapidly determined according to the eye opening template.

Owner:HUAWEI TECH CO LTD

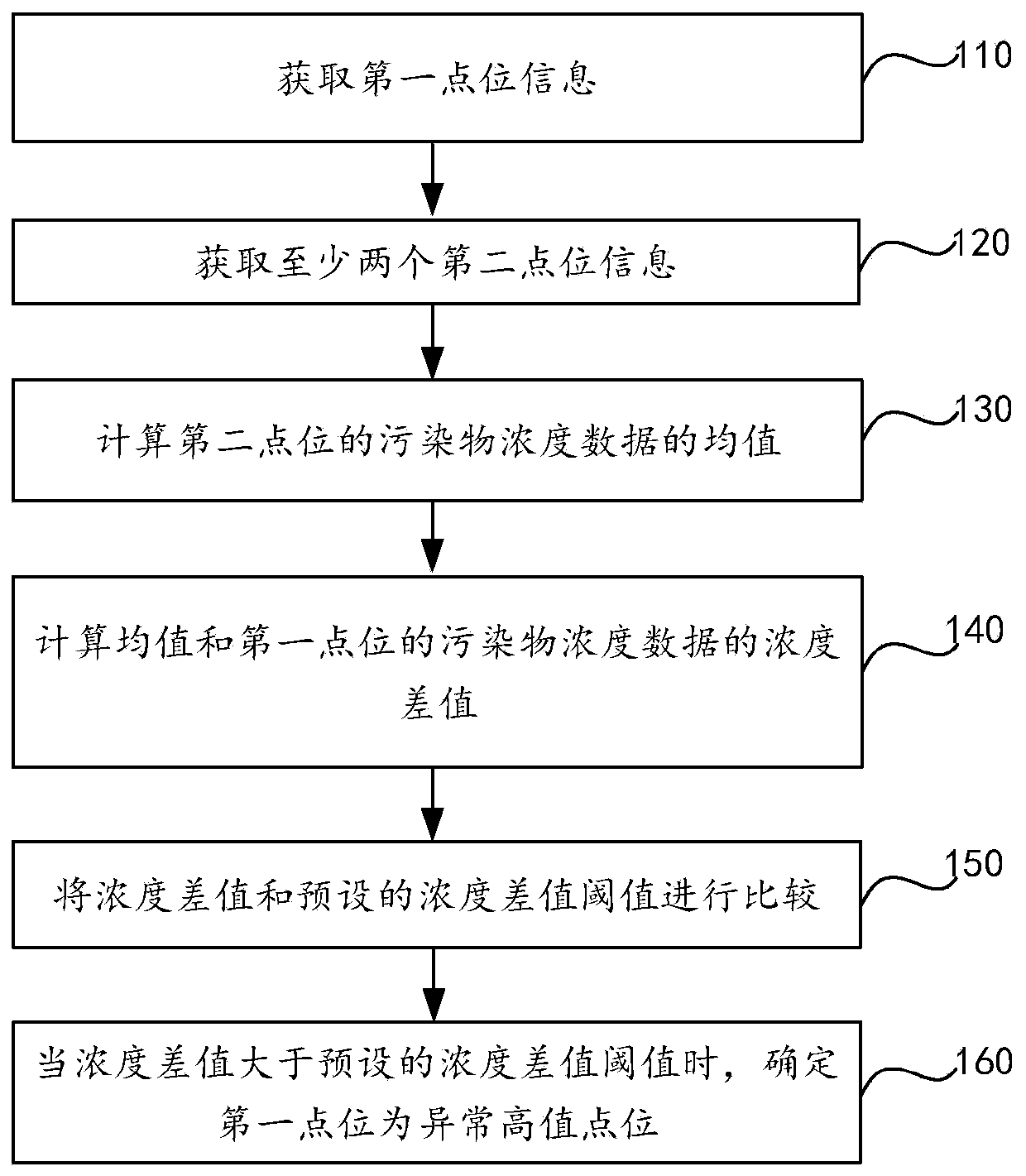

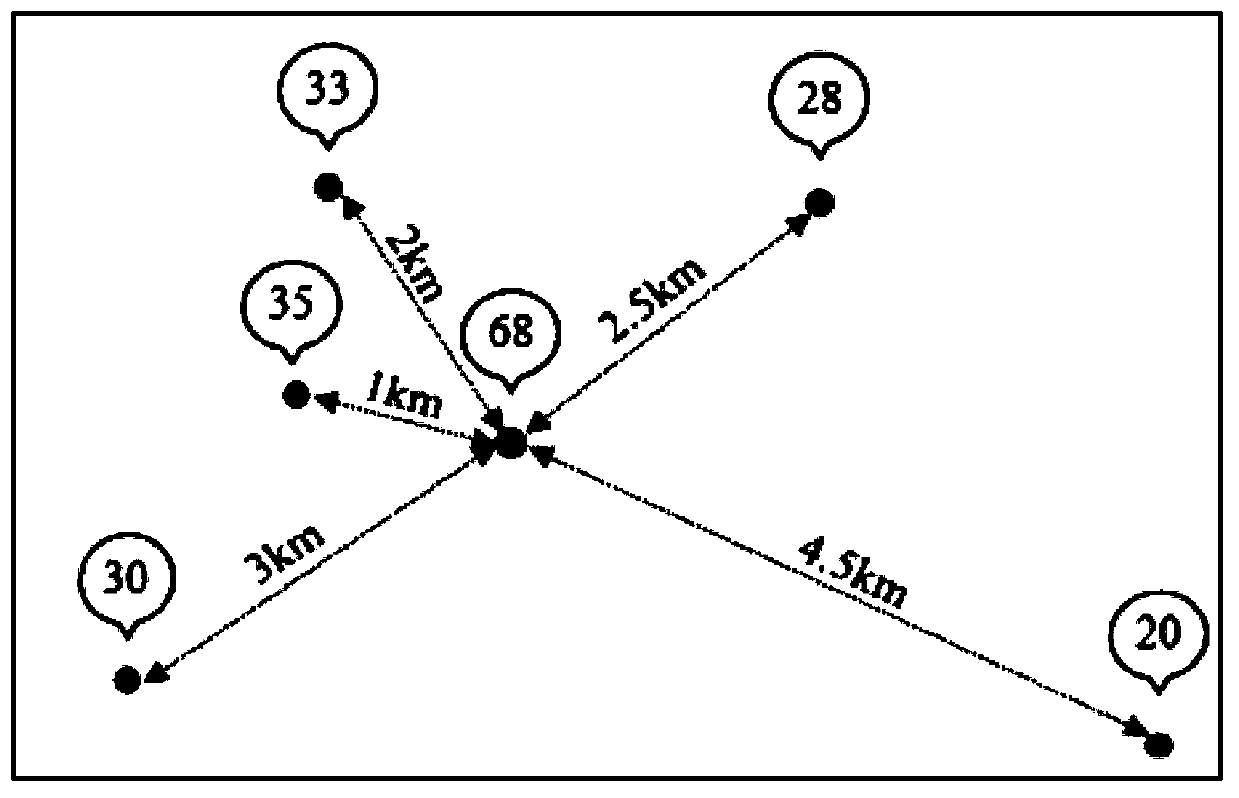

Method for determining abnormal high-value point

PendingCN109856321ASave human and material resourcesImprove effectivenessMaterial analysisEnvironmental monitoringMaterial resources

The invention provides a method for determining an abnormal high-value point, which includes the following steps: acquiring first point information, which includes the pollutant concentration data ofa first point; acquiring at least two pieces of second point information, which includes the pollutant concentration data of second points adjacent to the first point; calculating the mean value of the pollutant concentration data of the second points; calculating the concentration difference between the mean value and the pollutant concentration data of the first point; comparing the concentration difference with a preset concentration difference threshold; and determining that the first point is an abnormal high-value point when the concentration difference is greater than the preset concentration difference threshold. Thus, abnormal high-value points can be determined in real time, quickly and accurately, human and material resources are saved, the validity of the determination of abnormal high-value points is improved, and the accuracy and validity of the whole environmental monitoring work are improved.

Owner:BEIJING INSIGHTS VALUE TECHNOLOGY CO LTD

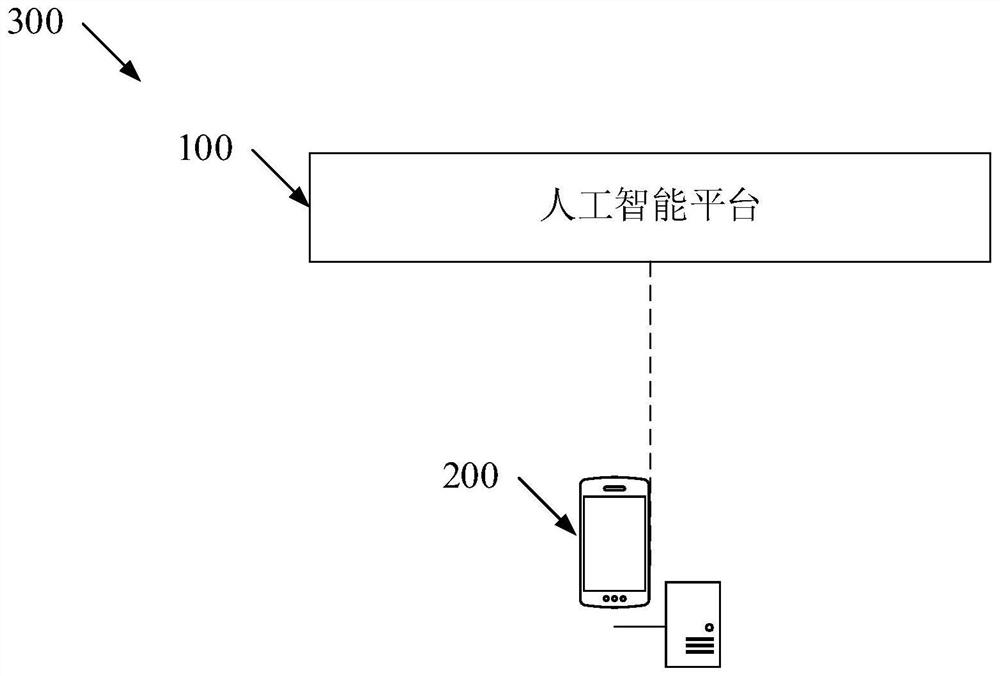

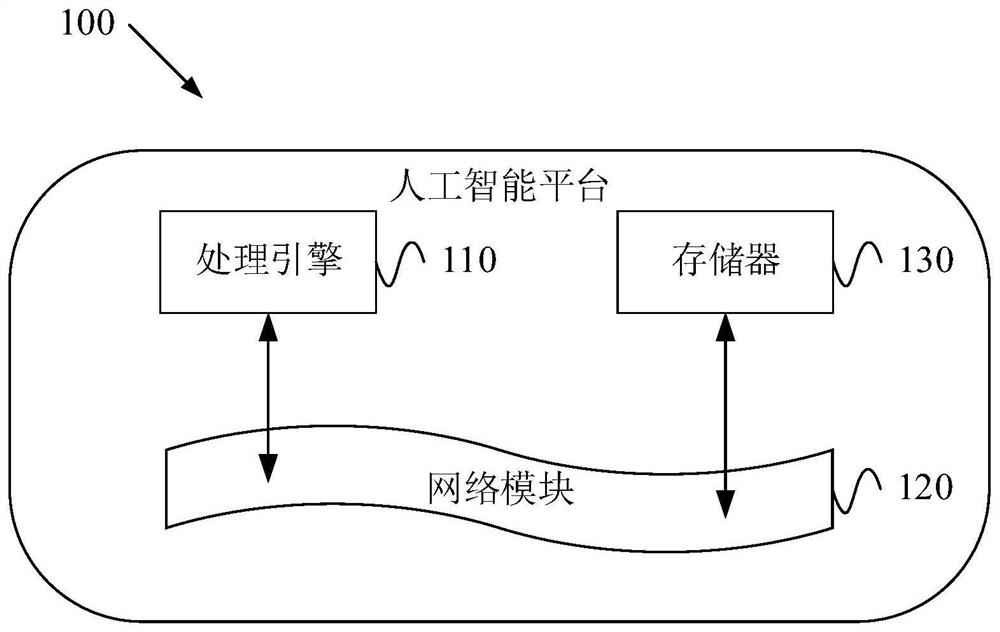

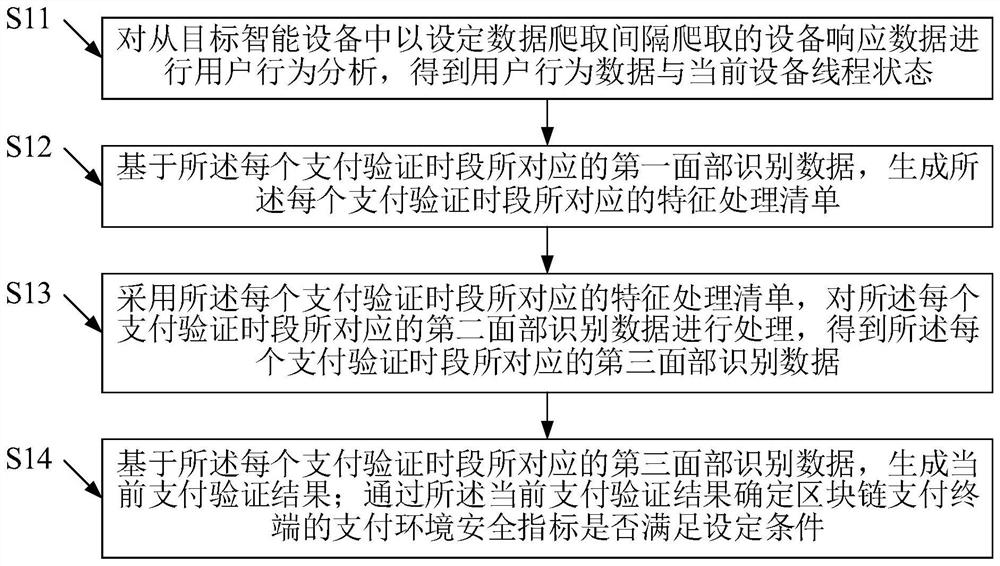

Advertisement pushing method based on big data and cloud computing and artificial intelligence platform

According to the advertisement pushing method based on big data and cloud computing and the artificial intelligence platform provided by the invention, during advertisement pushing, on one hand, userdemand analysis can be carried out on the user portrait label, so that the user demand information is determined, and the user demand information is paired with the data track identification result, the user demand information can be accurately determined in real time, so that the user matching degree of the to-be-pushed advertisement information and the current user can be ensured. On the other hand, by determining the target pushing time period, it can be ensured that normal use of the target intelligent device by the user is not affected during advertisement pushing, and meanwhile, influences on other threads are avoided. Thus, the user matching degree of advertisement pushing can be improved, it can be ensured that normal use of the target intelligent device is not affected when advertisements are pushed, and therefore the disturbance degree of advertisement pushing to users is reduced. In this way, the acceptance degree of the user to the pushed advertisement can be ensured, and then the advertisement pushing success rate is increased.

Owner:上海东方财富金融数据服务有限公司

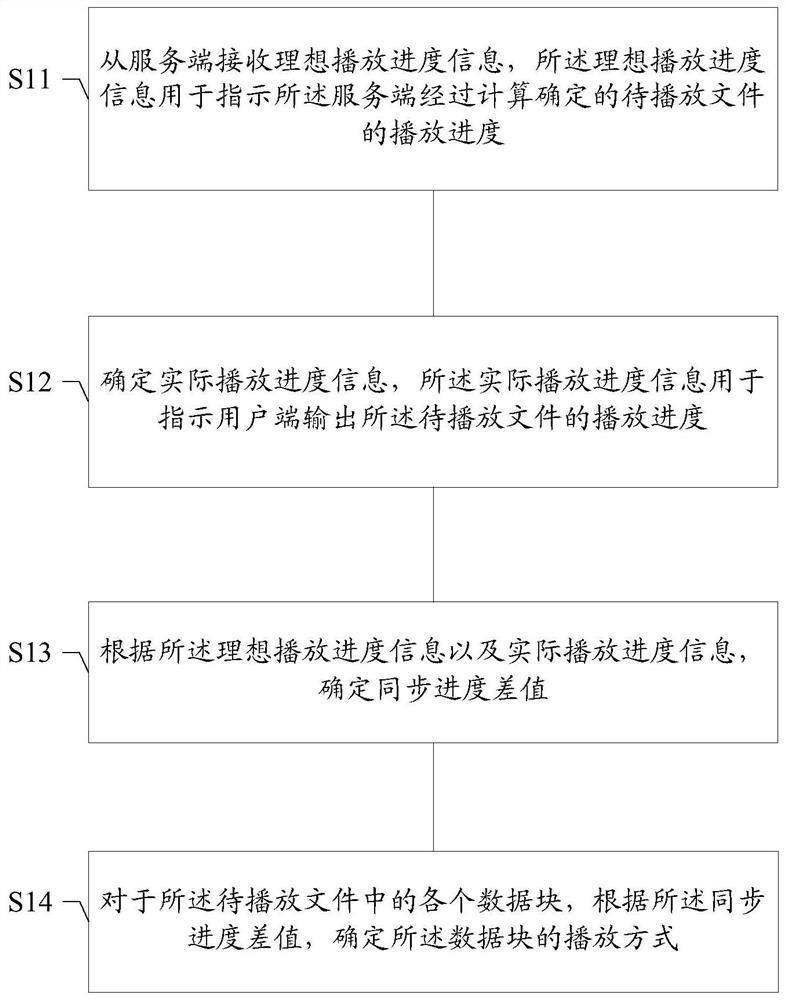

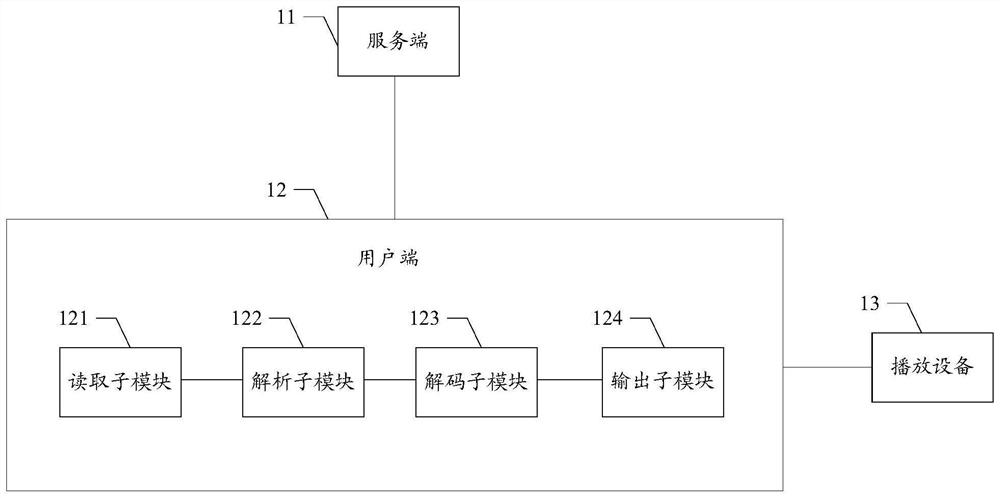

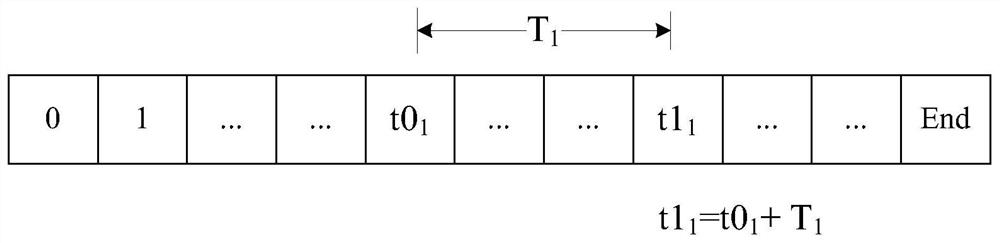

Playing synchronization method and device, storage medium and user side

InactiveCN112073791AHigh precisionAccurate synchronization targetSelective content distributionHuman–computer interactionServer-side

A playing synchronization method and device, a storage medium and a user side are disclosed. The method comprises: receiving ideal playing progress information from a server side, the ideal playing progress information being used for indicating a playing progress of a to-be-played file determined by the server side through calculation; determining actual playing progress information, wherein the actual playing progress information is used for indicating a user side to output the playing progress of the to-be-played file; determining a synchronization progress difference value according to theideal playing progress information and the actual playing progress information; and for each data block in the to-be-played file, determining a playing mode of the data blocks according to the synchronization progress difference. According to the invention, a more accurate synchronization target can be provided for each user side, so that the accuracy of each user side can be improved.

Owner:IAUTO (SHANGHAI) CO LTD

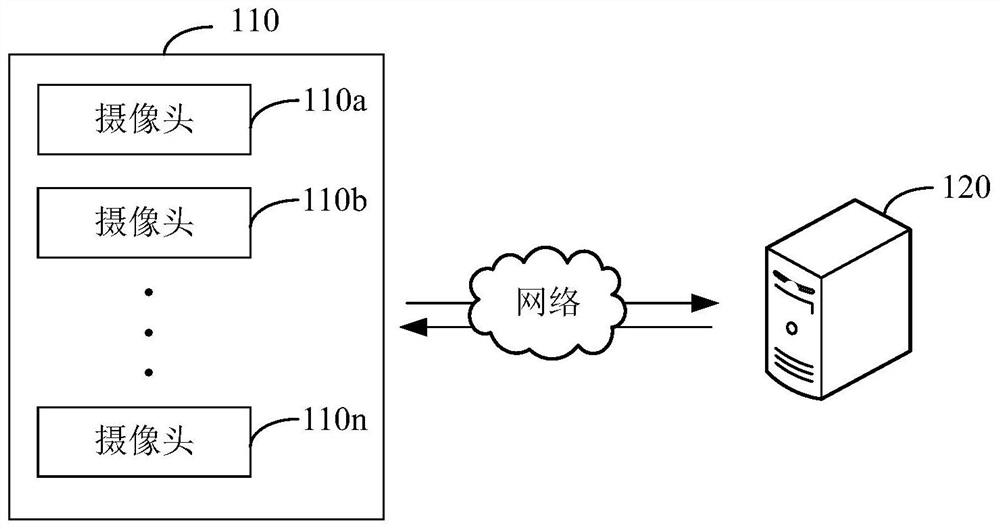

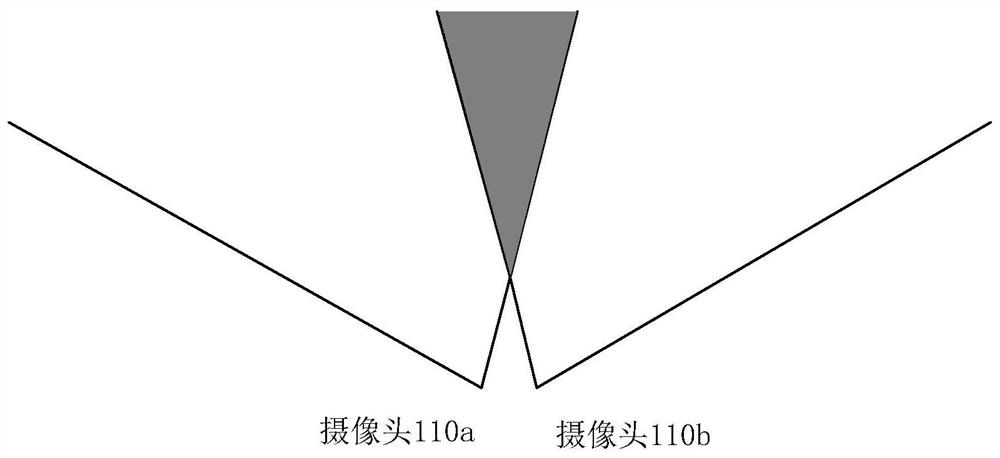

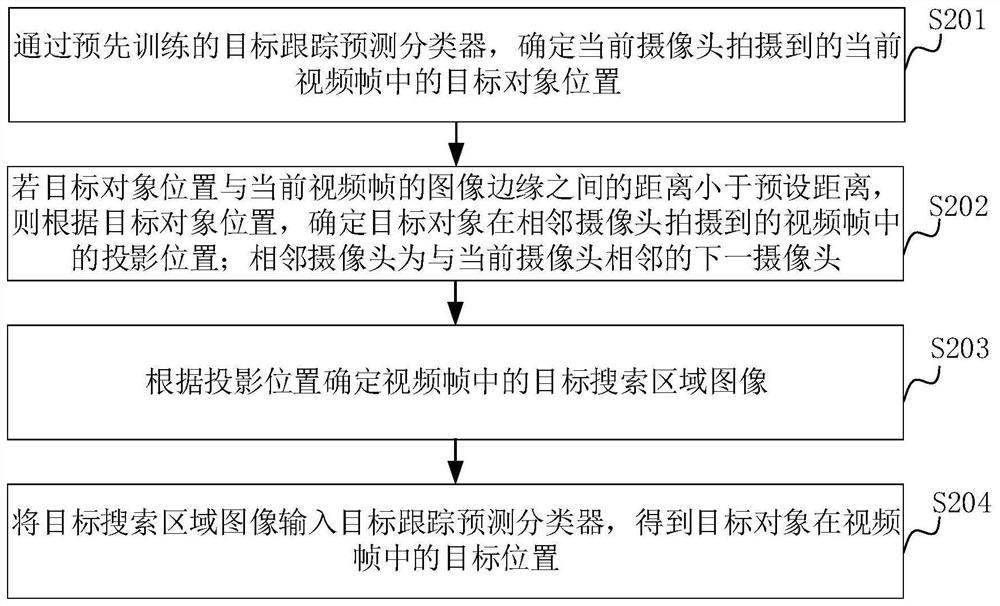

Target position determination method and device based on multiple cameras and computer equipment

PendingCN111612827AAvoid the pitfalls of lower accuracyImprove determination accuracyImage enhancementImage analysisComputer graphics (images)Radiology

The invention relates to a target position determination method and device based on multiple cameras, computer equipment and a storage medium. The method comprises the steps of determining a target object position in a current video frame shot by a current camera through a pre-trained target tracking prediction classifier; if the distance between the target object position and the image edge of the current video frame is smaller than the preset distance, determining the projection position of the target object in the video frame shot by the adjacent camera according to the target object position, wherein the adjacent camera is the next camera adjacent to the current camera; determining a target search area image in the video frame according to the projection position; and inputting the target search area image into a target tracking prediction classifier to obtain a target position of the target object in the video frame. By adopting the method, the position of the target object is tracked and positioned through the plurality of cameras, so that the determination accuracy of the target position is improved.

Owner:GUANGZHOU HAIGE COMM GRP INC +1

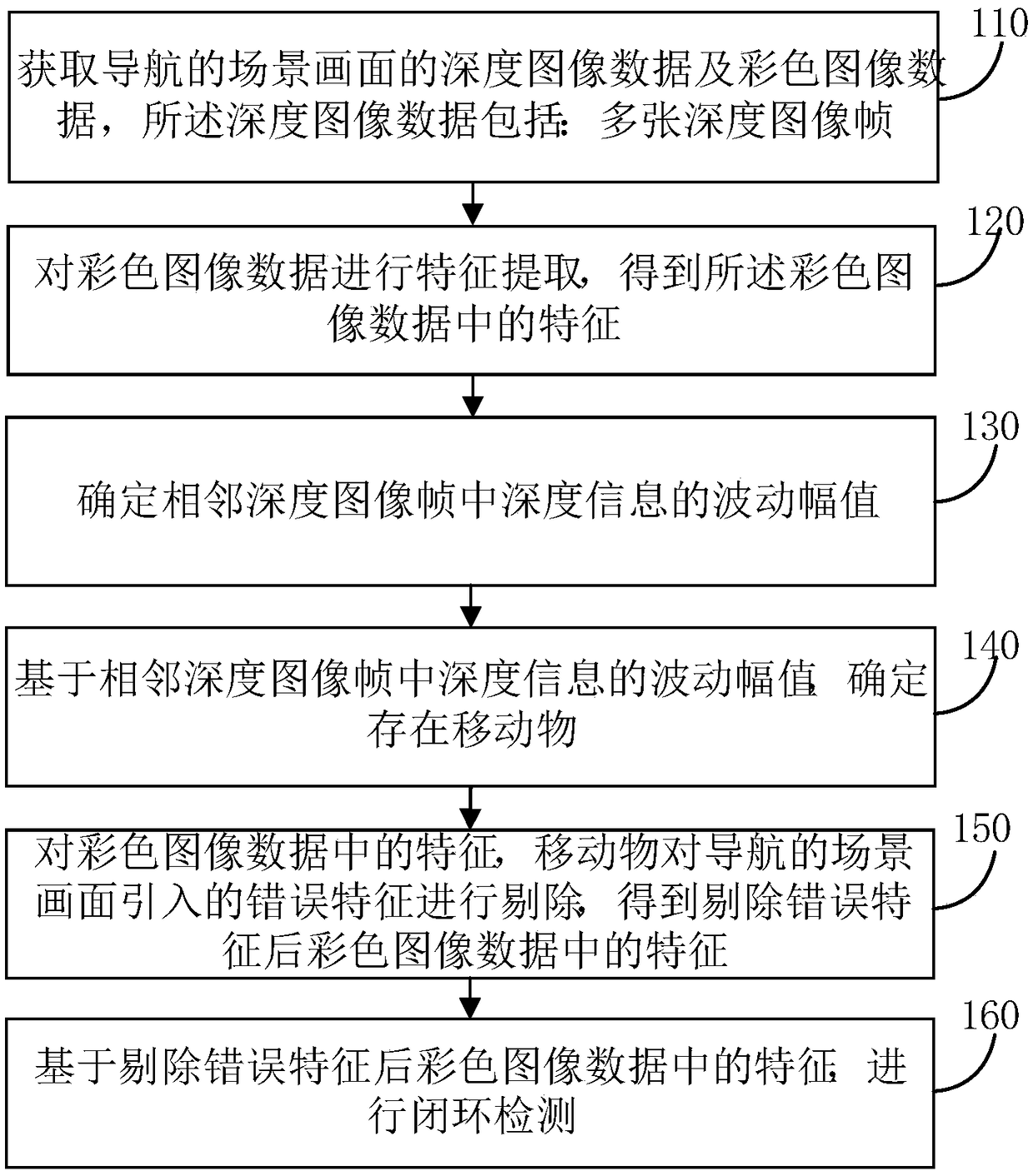

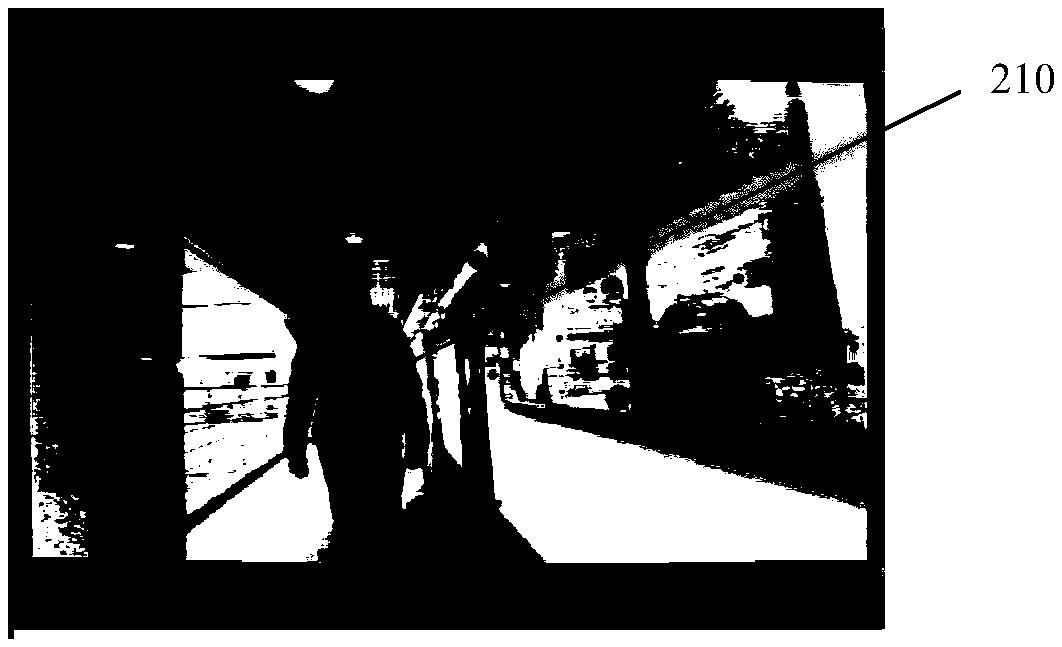

A method and apparatus for closed-loop detection of scene pictures based on depth information

The embodiment of the invention provides a method and a device for performing closed-loop detection on a scene picture based on depth information. The method comprises the following steps: acquiring depth image data and color image data of a navigation scene picture; performing feature extraction on the color image data to obtain features in the color image data; determining a fluctuation amplitude of depth information in adjacent depth image frames; determining the presence of a moving object based on a fluctuation amplitude of depth information in the adjacent depth image frame; removing thefeatures in the color image data, and the moving object removes the error features introduced in the scene picture of the navigation to obtain the features in the color image data after removing theerror features; a closed loop detection being performed based on features in the color image data after removing the erroneous features.

Owner:BEIJING UNIV OF POSTS & TELECOMM

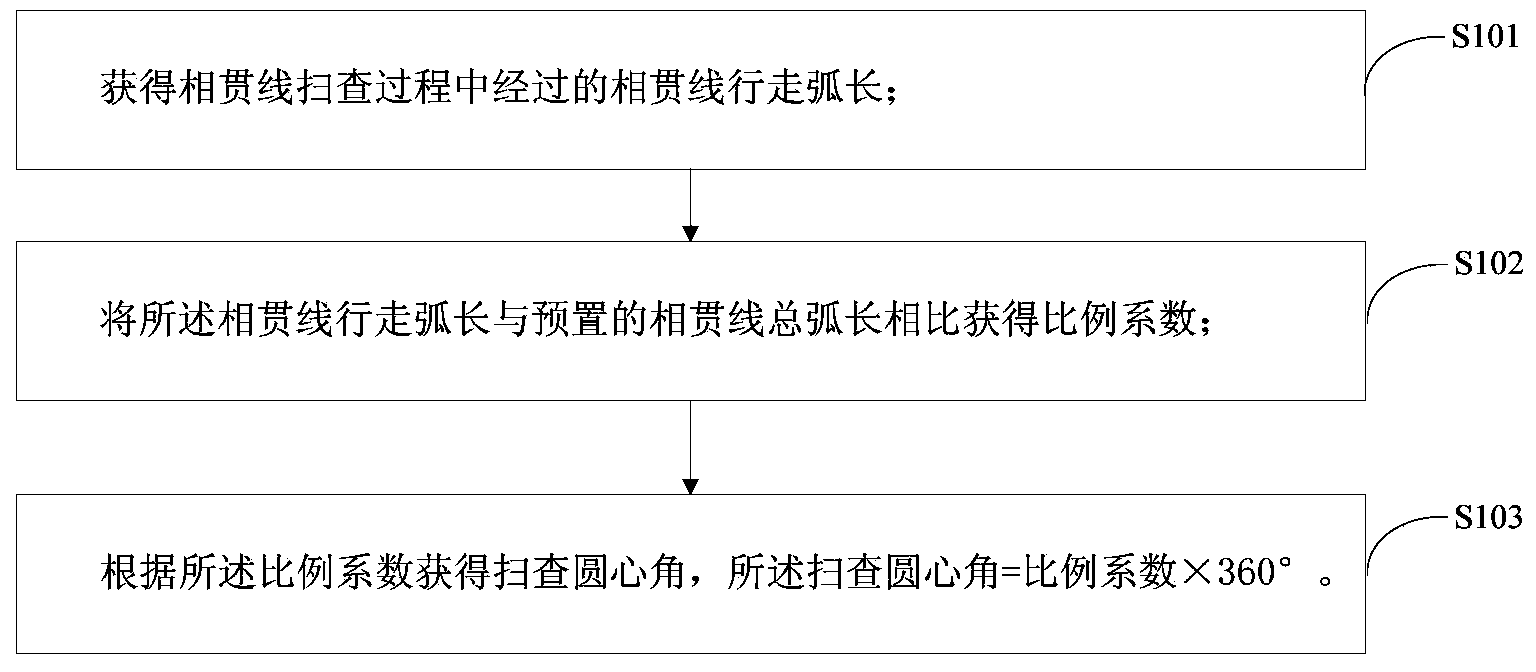

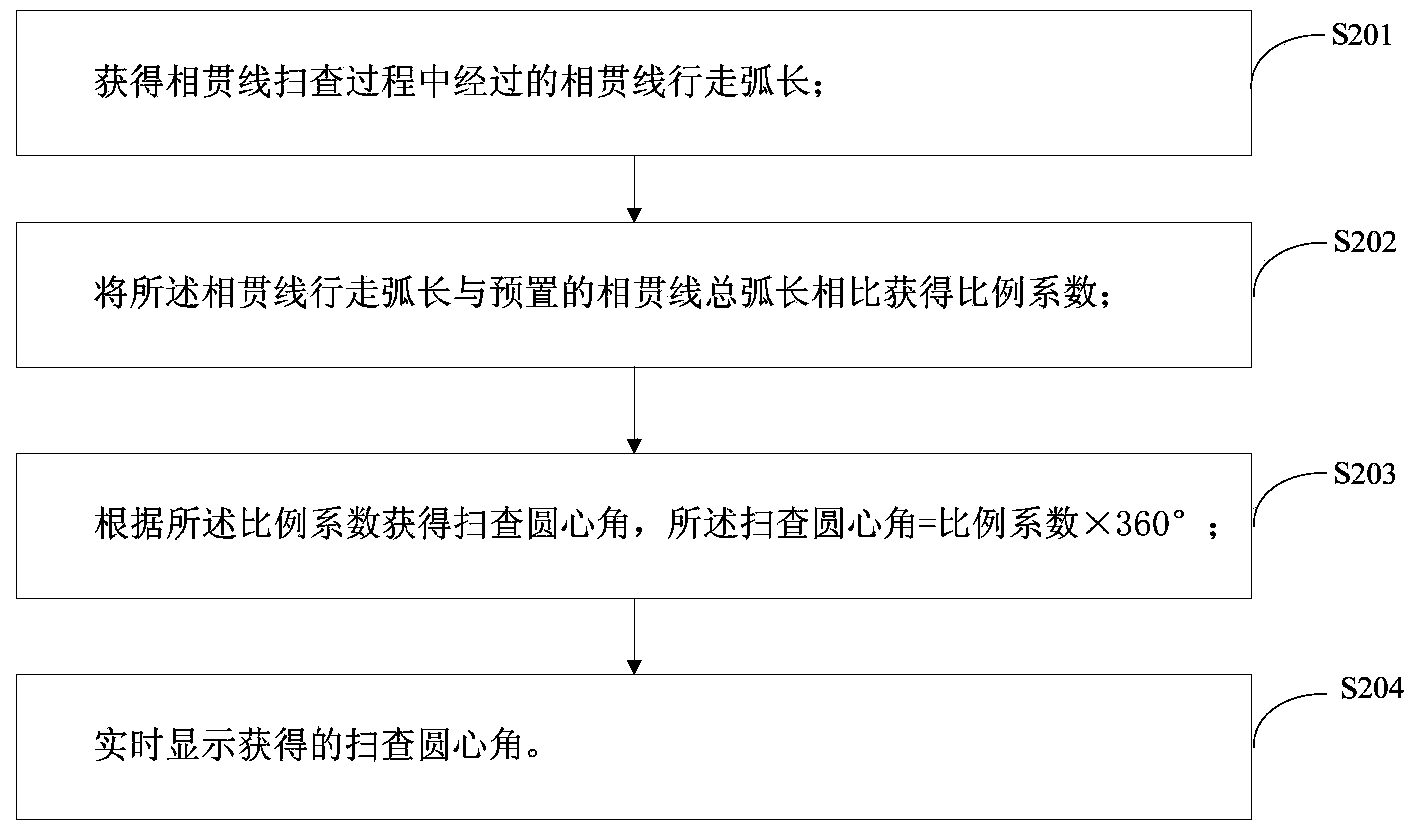

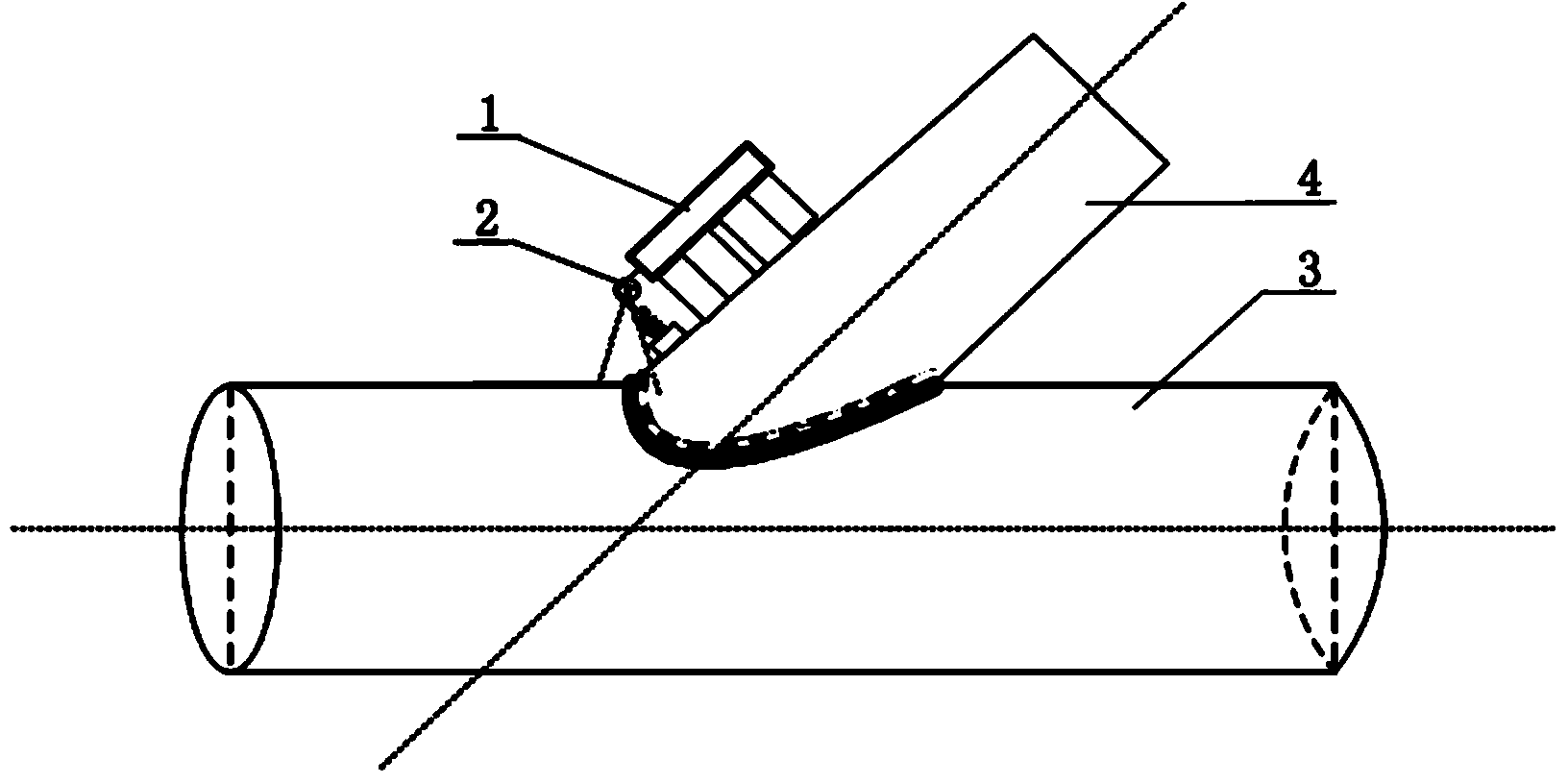

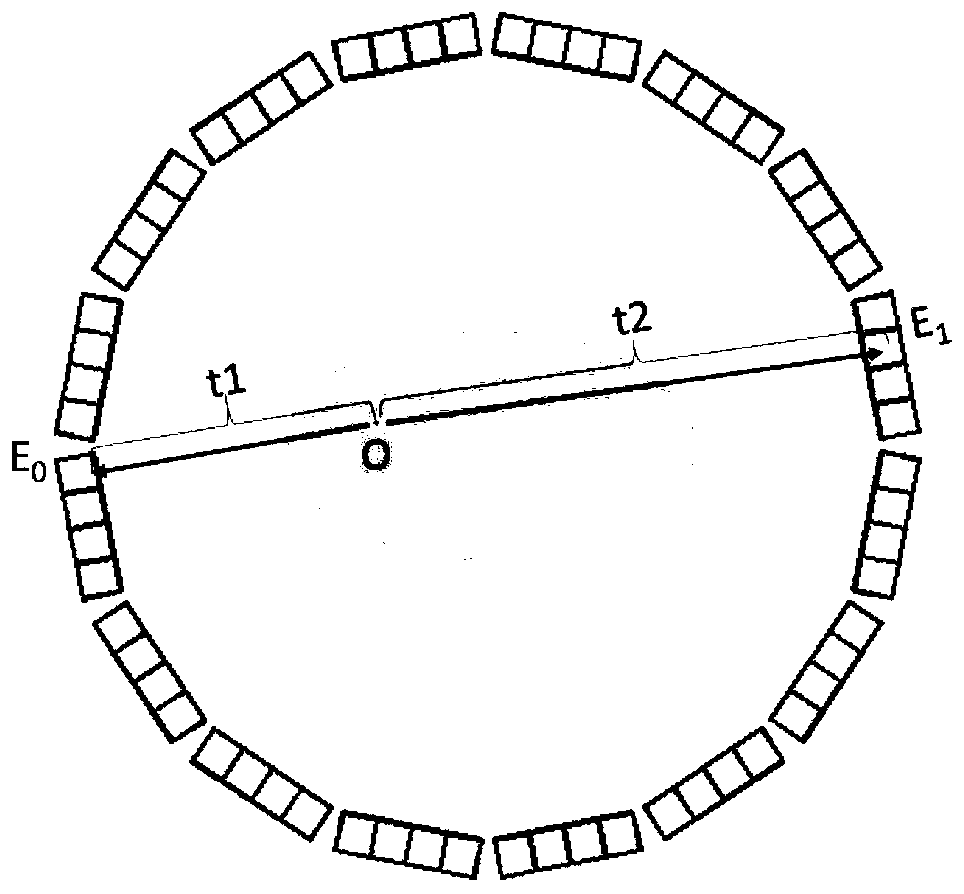

Method and device for determining intersecting line scanning central angle for pipe welding

ActiveCN104345089AOK real timeImprove reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringPipe welding

The invention relates to a method and a device for determining an intersecting line scanning central angle for pipe welding. The device comprises a traveling arc length acquisition module, a proportional coefficient acquisition module and a central angle acquisition module, wherein the traveling arc length acquisition module is used for acquiring an intersecting line traveling arc length in an intersecting line scanning process; the proportional coefficient acquisition module is used for comparing the intersecting line traveling arc length with a preset total intersecting line arc length to obtain a proportional coefficient; the central angle acquisition module is used for acquiring the scanning central angle according to the proportional coefficient; the scanning central angle is obtained by multiplying the proportional coefficient with 360 degrees. Therefore, according to the method and the device for determining the intersecting line scanning central angle for pipe welding, the proportional relation between the traveling arc length during intersecting line scanning and the total arc length of an intersecting line is converted into the scanning central angle, so that the intersecting line scanning central angle can be determined in real time, and the reliability of an ultrasonic flaw detection result is improved.

Owner:SENSE ENG SERVICES

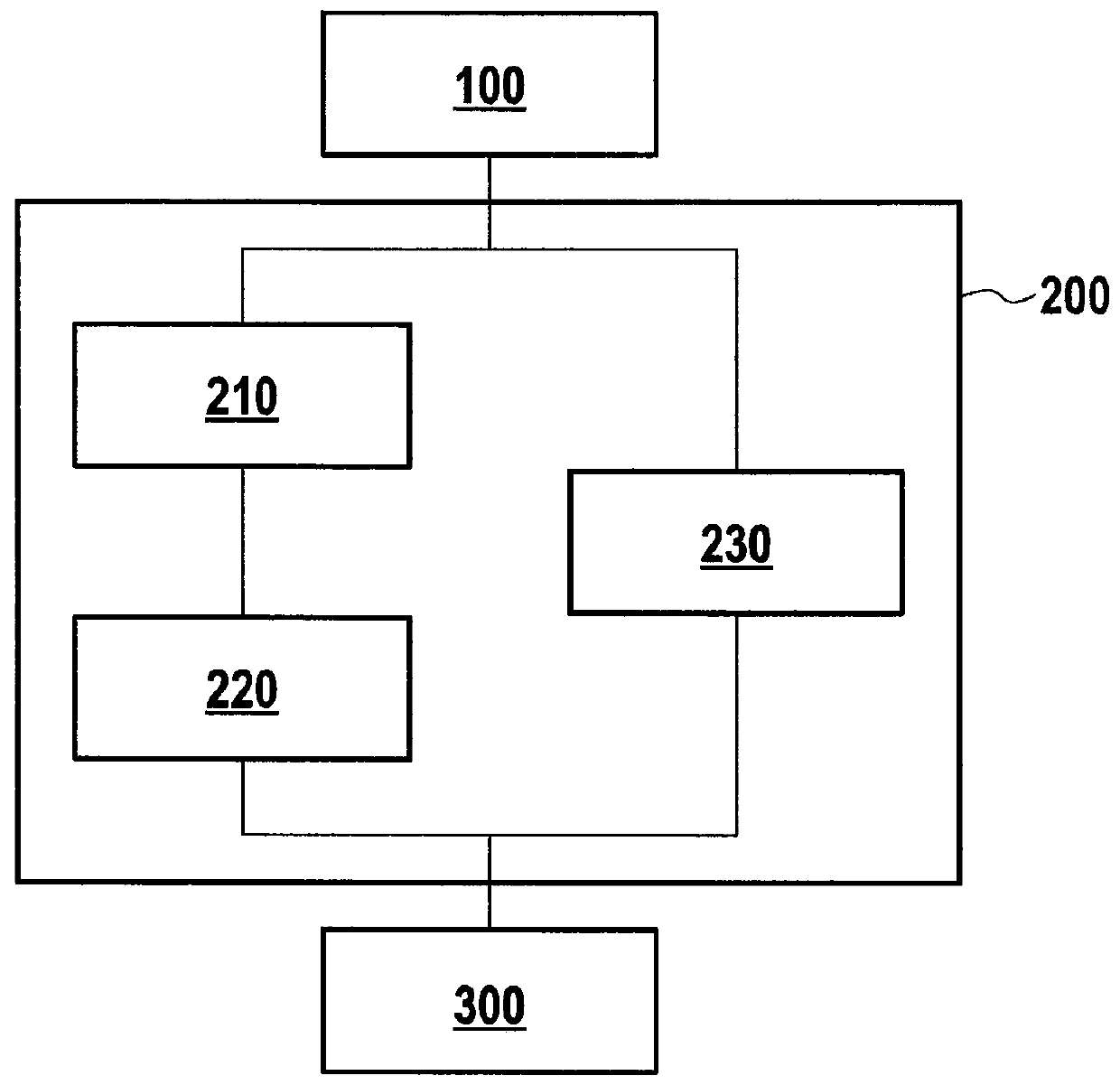

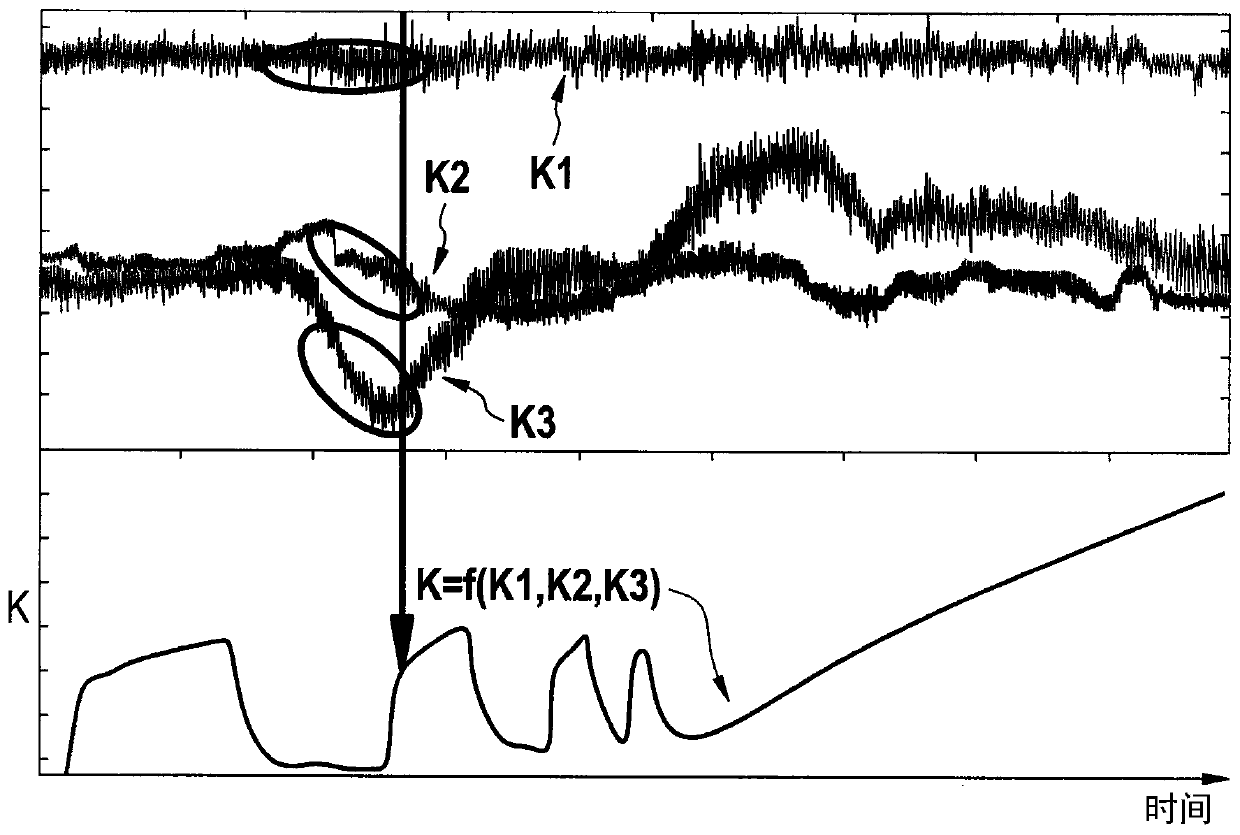

Method and device for determining a driving behaviour

ActiveCN110997441AReal-time driving behaviorOK real timeRegistering/indicating working of vehiclesExternal condition input parametersDriver/operatorOutput device

Owner:ROBERT BOSCH GMBH

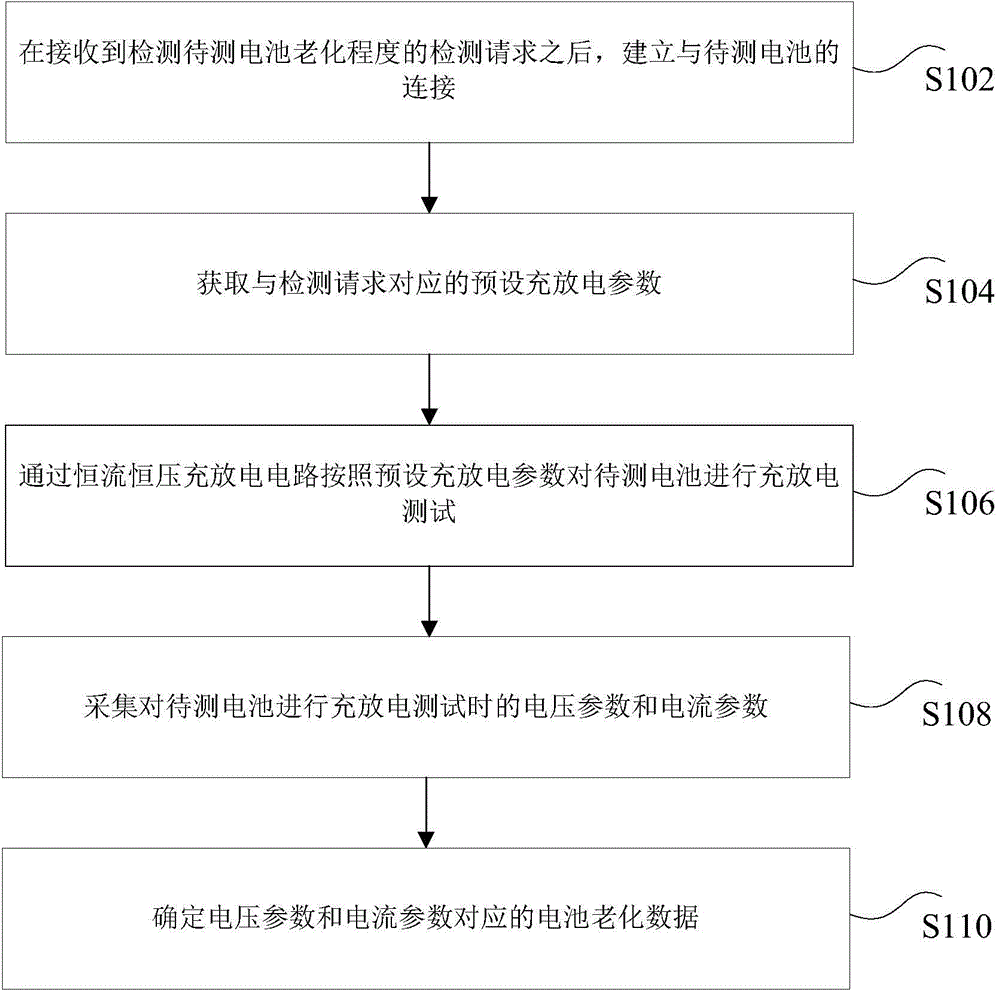

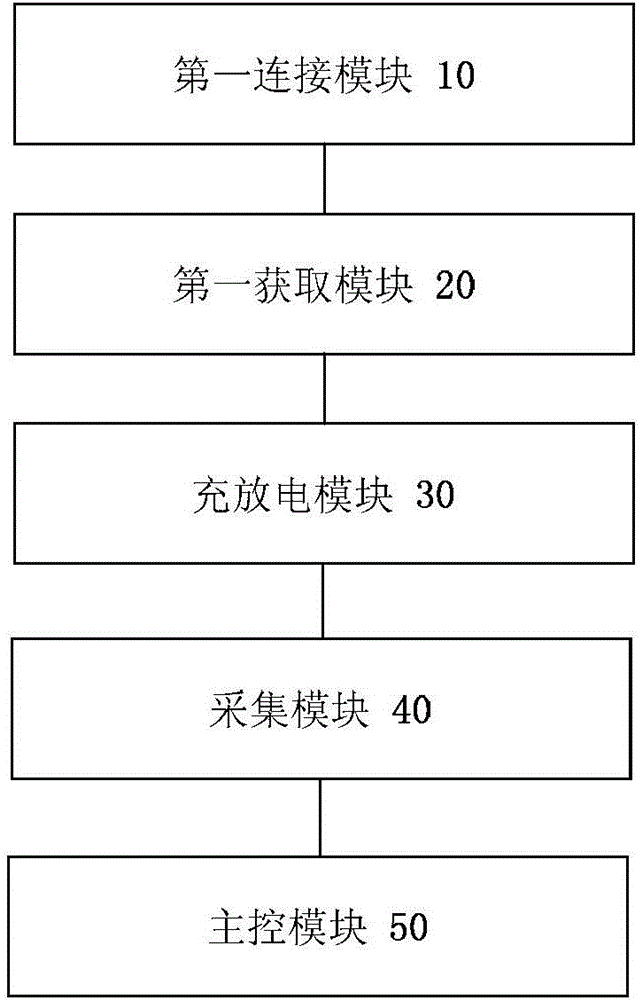

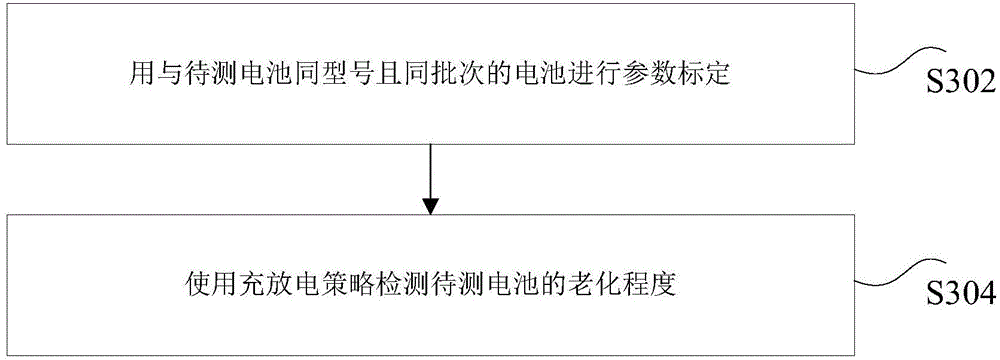

Aging detection method and device for individual battery

InactiveCN104569840AHigh-precision detectionImprove accuracyElectrical testingEngineeringElectrical current

The invention discloses an aging detection method and device for an individual battery. The method comprises the following steps: establishing a connection with a to-be-detected battery after receiving a detection request of detecting the aging degree of the to-be-detected battery; obtaining preset charge / discharge parameters corresponding to the detection request; performing a charge / discharge test on the to-be-detected battery according to the preset charge / discharge parameters through a constant-current constant-voltage charge / discharge circuit; acquiring a voltage parameter and a current parameter during the charge / discharge test of the to-be-detected battery; determining battery aging data corresponding to the voltage parameter and the current parameter. With the aging detection method and device, a problem of low detection speed of the aging degree of the battery in the prior art is solved and an effect of quickly and accurately detecting the aging degree of the individual battery is achieved.

Owner:STATE GRID CORP OF CHINA +4

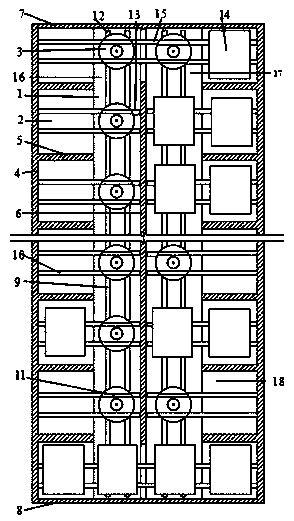

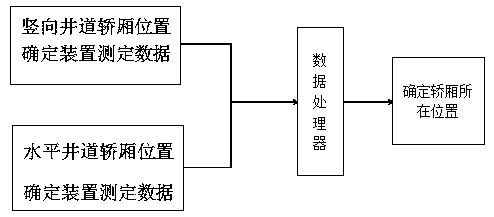

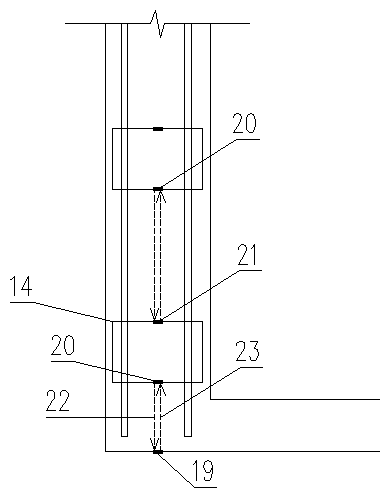

Car position determining method for multi-car elevator system

InactiveCN109205417AOK real timeHigh precisionUsing optical meansElevatorsElevator systemEngineering

The invention provides a car position determining method for a multi-car elevator system comprising a vertical hoistway car position determining device and a horizontal hoistway car position determining device. The car position determining method comprises the following steps: the vertical hoistway car position determining device and the horizontal hoistway car position determining device simultaneously work to measure data, the vertical hoistway car position determining device transmits the reflection time to a data processor, the horizontal hoistway car position determining device transmitsthe pressed position to the data processor, and the data processor determines real-time positions of all the cars in the hoistway. The beneficial effects of the invention are that the vertical hoistway car position determining device works simultaneously with the horizontal hoistway car position determining device, the positions of all the cars can be determined in real time, the accuracy and real-time performance of the plurality of car positions simultaneously determined are improved, and an elevator dispatch system is provided with more accurate real-time positions of the cars.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

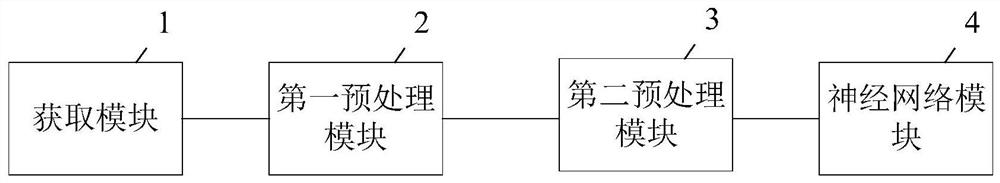

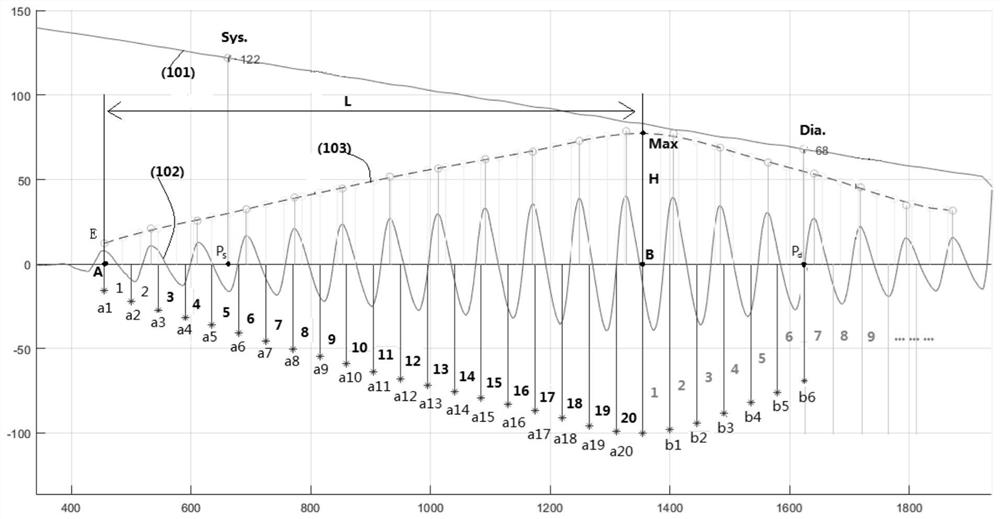

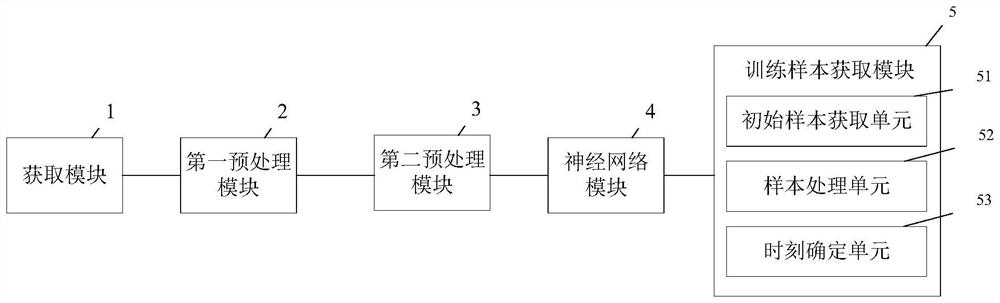

Pressure value determination system, method and device and readable storage medium

PendingCN114692668AOK real timeLearn in real timeEvaluation of blood vesselsCharacter and pattern recognitionNetwork modelPressure data

The invention discloses a pressure value determination system, method and device and a readable storage medium, and the system comprises an obtaining module, a first preprocessing module, a second preprocessing module and a neural network module which is used for inputting envelope difference waveform data and pressure change trend waveform data into a neural network model, the neural network model outputs diastolic pressure and systolic pressure of the to-be-measured pressure data; wherein the neural network model is specifically a neural network model obtained by training and learning pressure training samples, and the pressure training samples comprise envelope difference waveform samples and pressure change trend waveform samples corresponding to pressure data samples; a diastolic pressure sample and a diastolic pressure moment of the diastolic pressure sample on the pressure change trend waveform sample; systolic pressure samples and systolic pressure moments thereof on the pressure variation trend waveform samples. According to the method, the numerical values and positions of the diastolic pressure and the systolic pressure can be accurately judged according to the to-be-measured pressure data, and the method has the advantages of self-adaption, self-organization and real-time learning.

Owner:CONTEC MEDICAL SYST

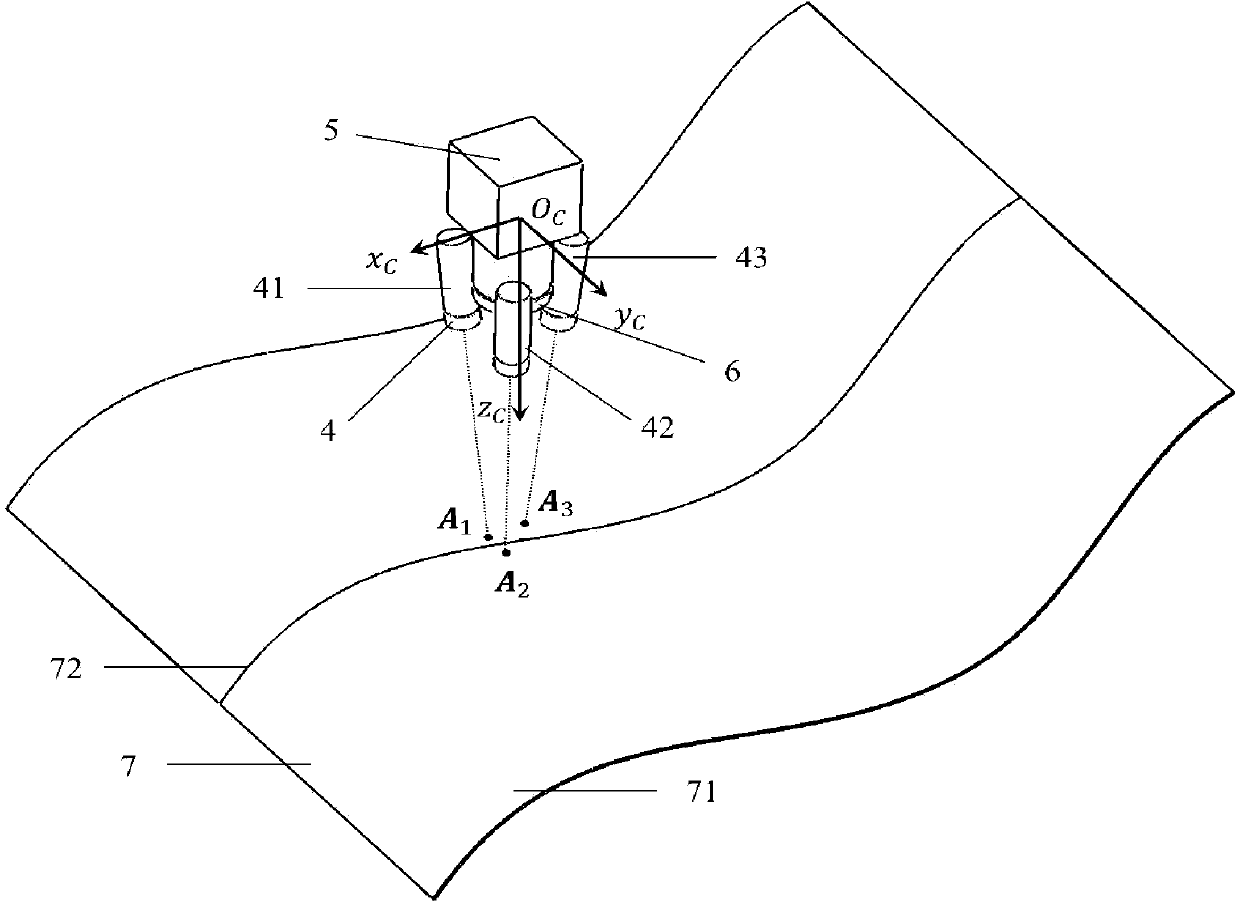

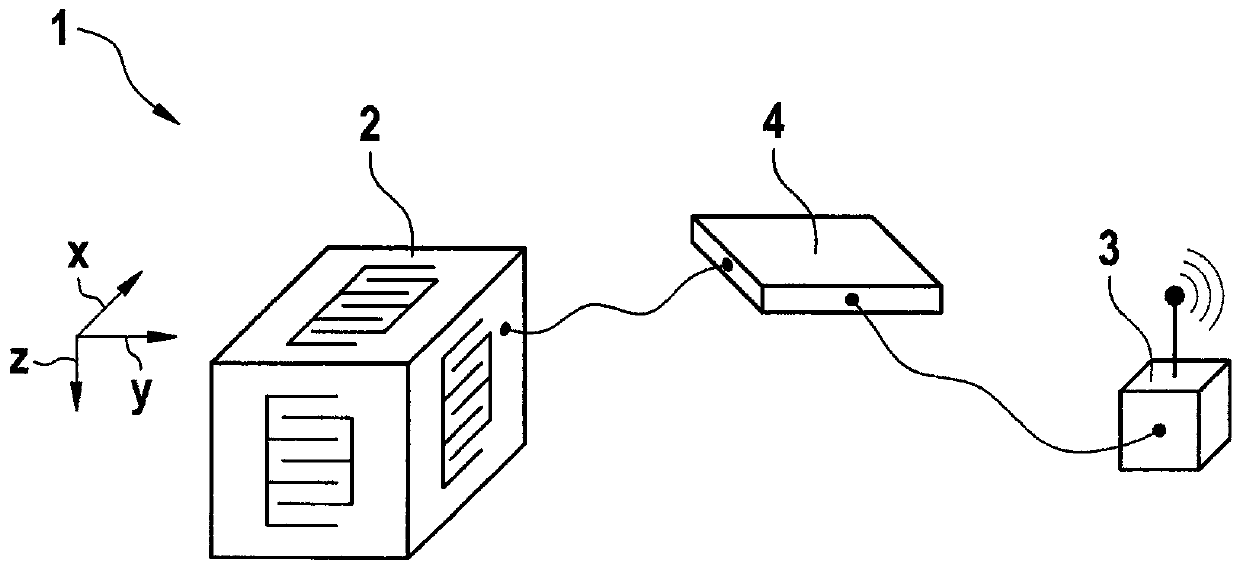

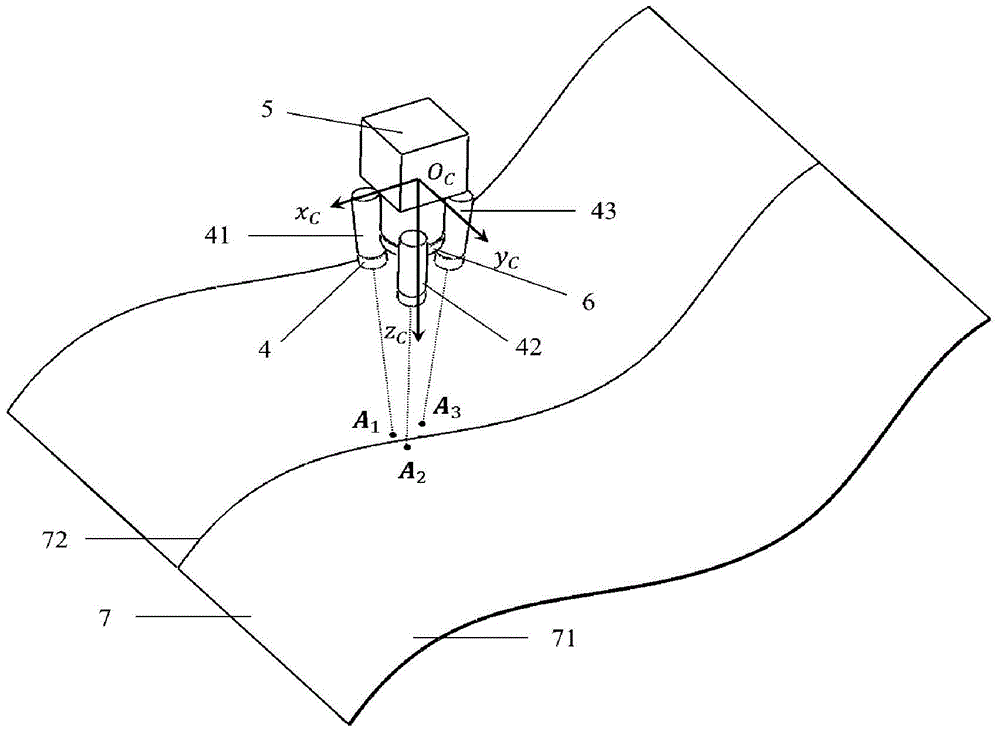

Thin and narrow groove detection device and method of strong specular reflection workpiece based on spherical light source

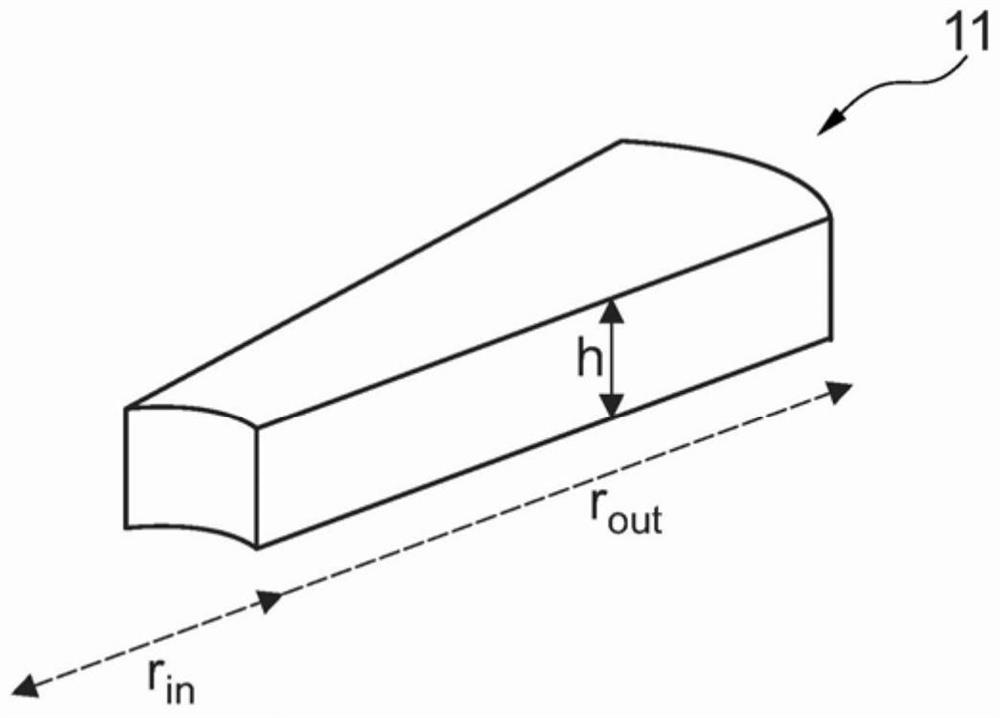

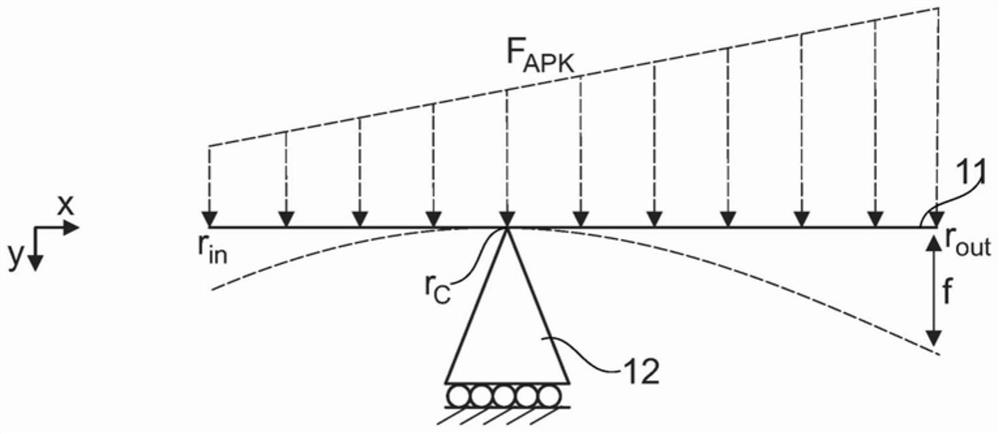

ActiveCN103954216BOK real timeAccurately determineArc welding apparatusUsing optical meansLaser arrayLaser light

An apparatus and a method for detecting a narrow groove (72) of a specular reflection workpiece are provided. The apparatus includes: a spherical light source (3) configured to generate a uniform illumination on a workpiece surface (7); a laser array (4) having at least three lasers and configured to emit a laser light onto the workpiece surface (7); an imaging unit (5) configured to sample a light from the workpiece surface (7) to generate an image thereof; and a control unit (1) configured to control the spherical light source (3) and the laser array (4) to illuminate the workpiece surface (7) alternately, to control the imaging unit (5) to sample the image of the illuminated workpiece surface (7) respectively, to calculate a pose of a welding torch (8) with respect to the workpiece and a position of a center point of the groove (72) according to the image.

Owner:TSINGHUA UNIV

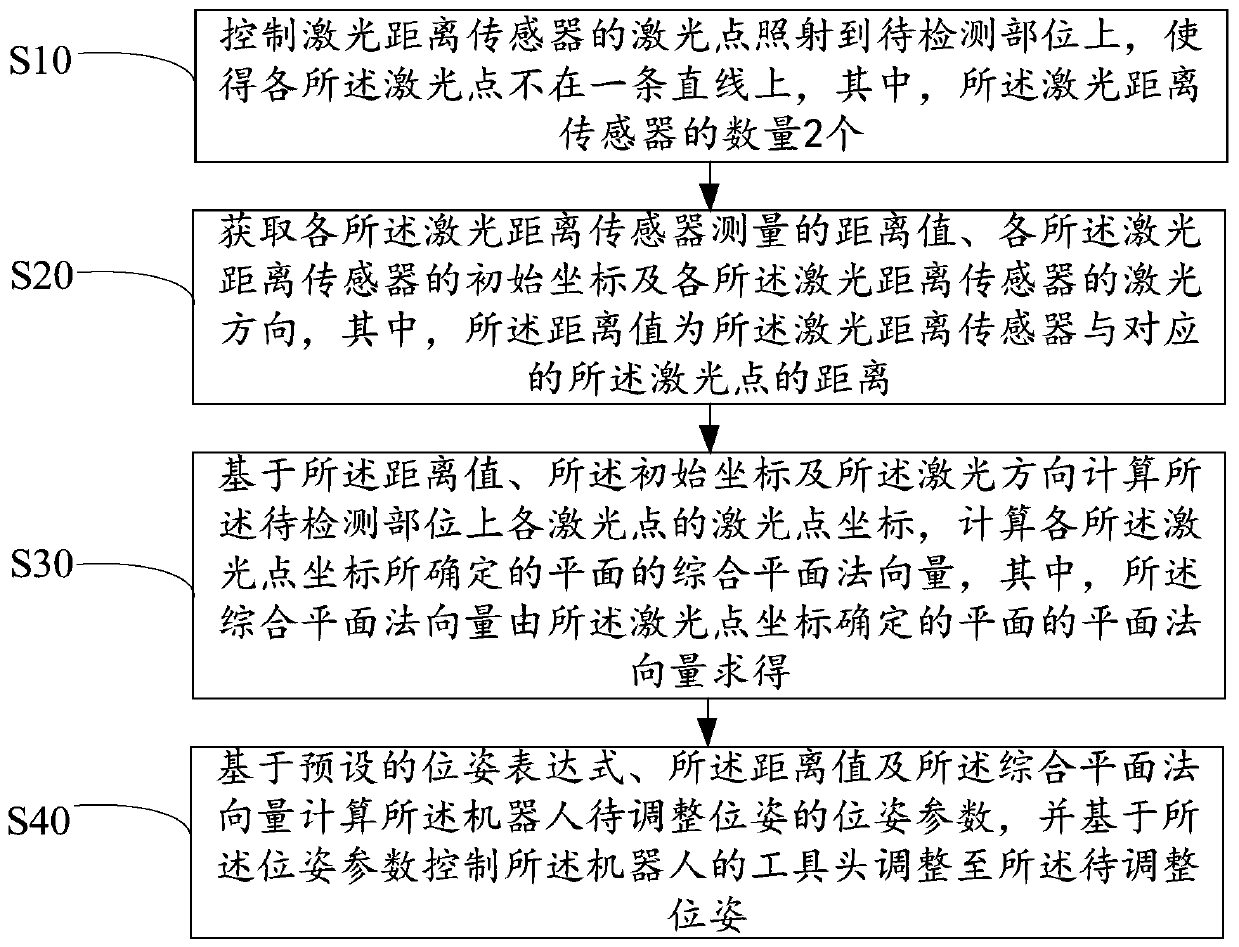

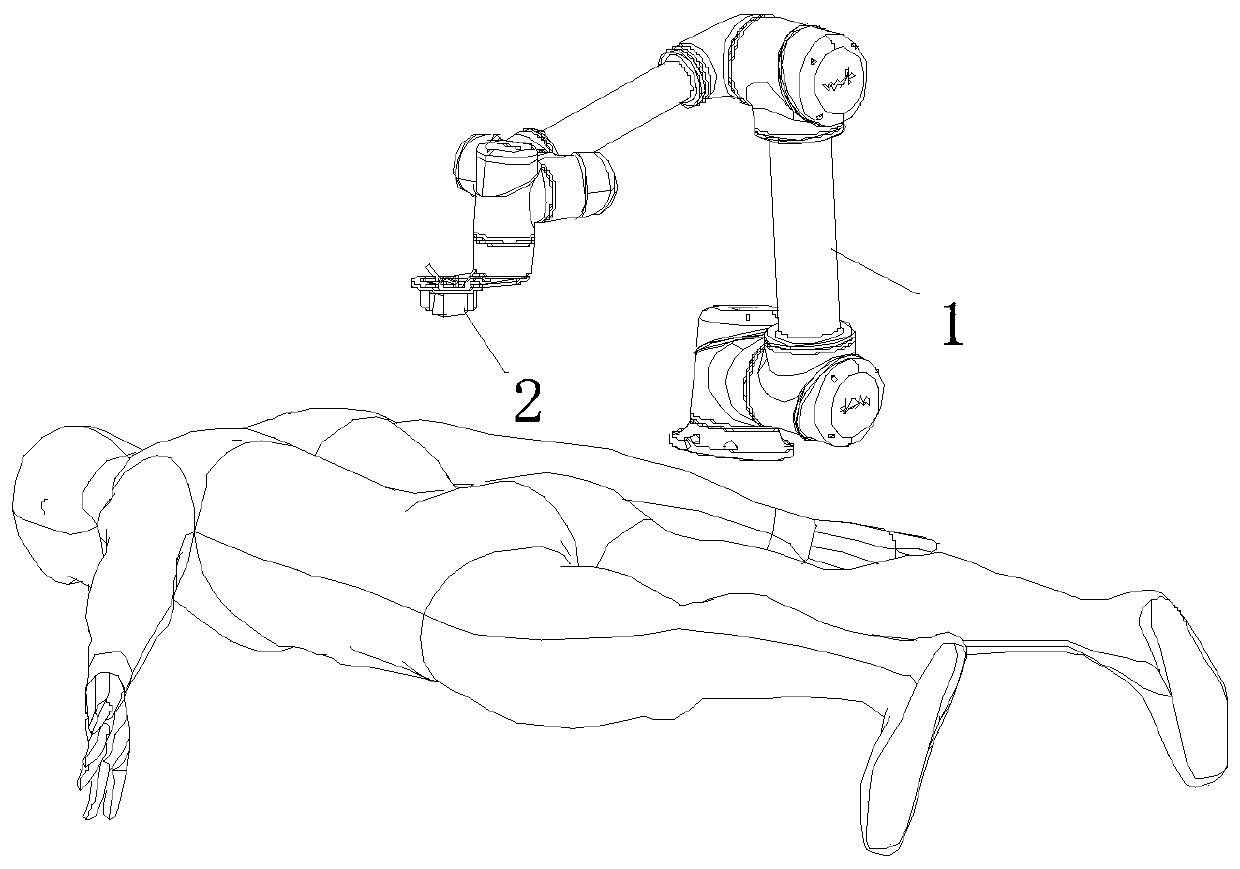

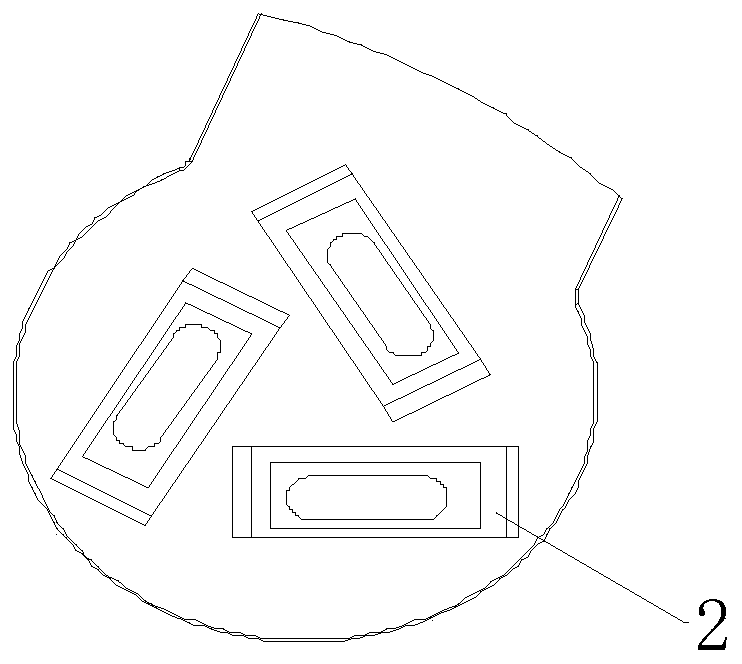

Tool head pose adjusting method and device and readable storage medium

ActiveCN111438689AEasy to adjustReal-time adjustmentProgramme controlProgramme-controlled manipulatorHuman bodyEngineering

The invention discloses a tool head pose adjusting method and device and a readable storage medium. Laser distance sensors are used for detecting the distance value of laser points, at least one planecan be constructed by the laser points, accordingly, various planes corresponding to to-be-detected parts can be determined, the comprehensive normal vector of various planes is calculated, pose parameters of a robot tool head are calculated through the pose expression, and accordingly the pose of the tool head is adjusted. By means of the tool head pose adjusting method and device and the readable storage medium, the pose parameters of the to-be-adjusted pose of the tool head can be accurately determined, and accordingly the operation efficiency of a moxa-moxibustion instrument is improved;and in addition, the cost of the laser distance sensors is low, when the robot operates, precision is high, real-time performance is high, and the robot can adapt to the tool head and human body contact type scene or the scene where a certain distance is kept from the human body.

Owner:ZHI MEI KANG MIN ZHUHAI HEALTH TECH CO LTD

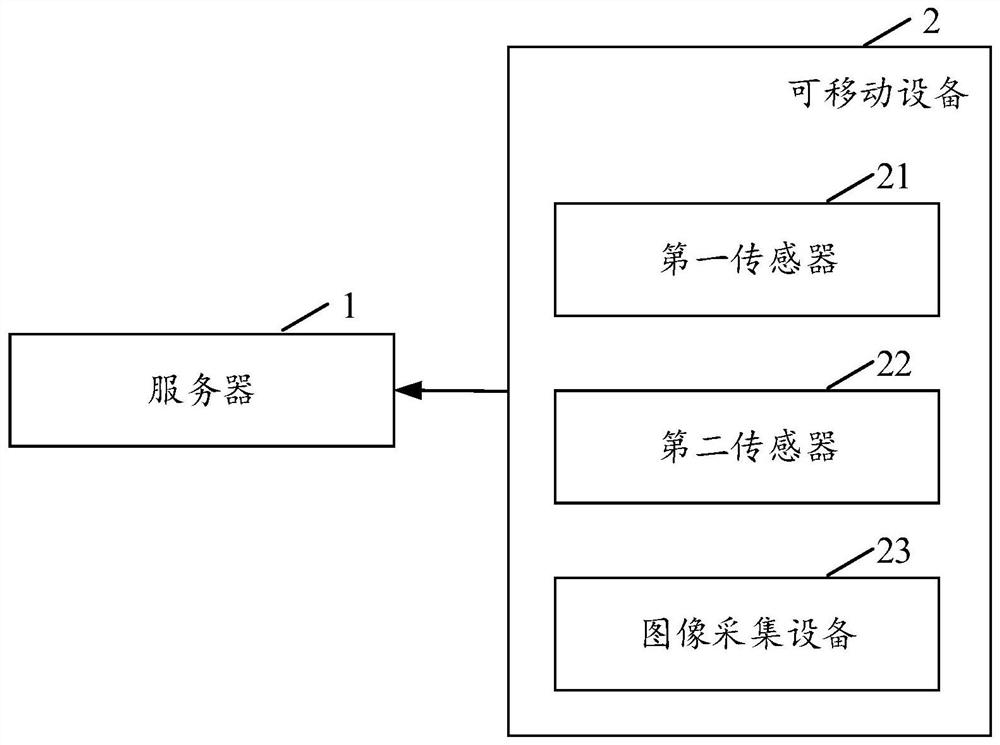

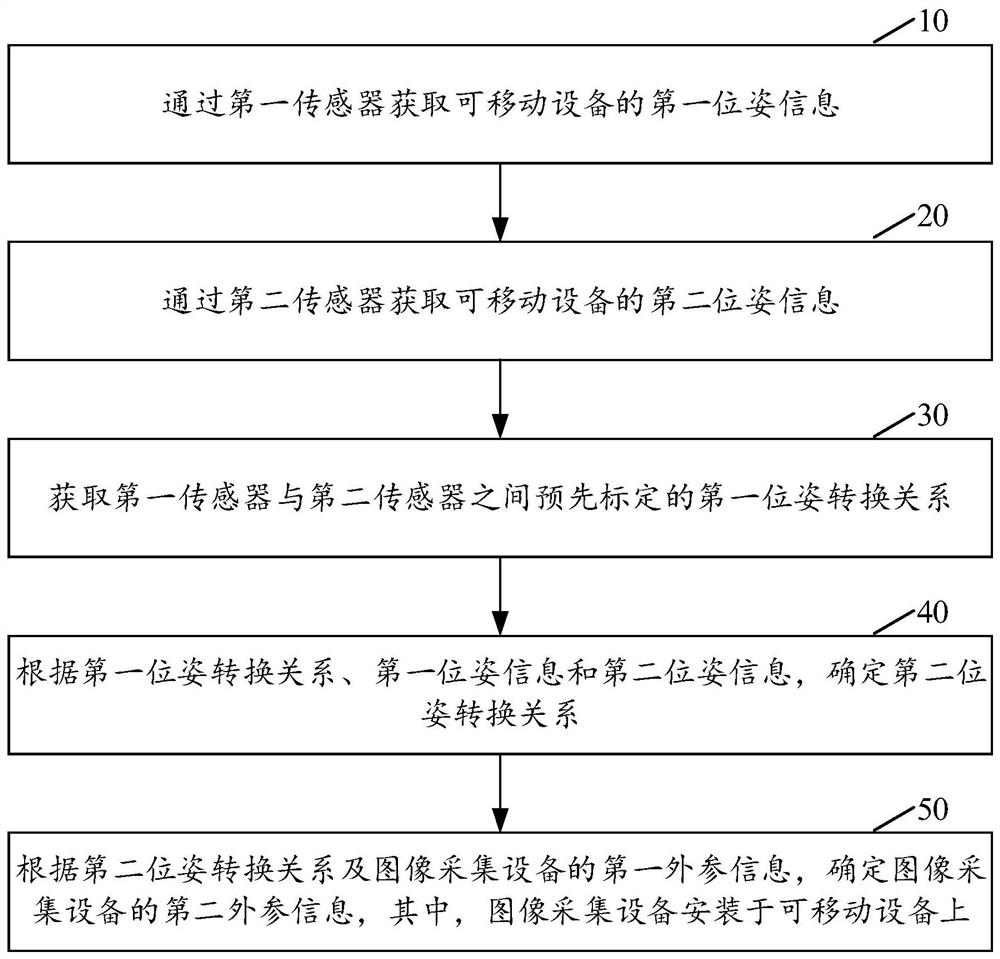

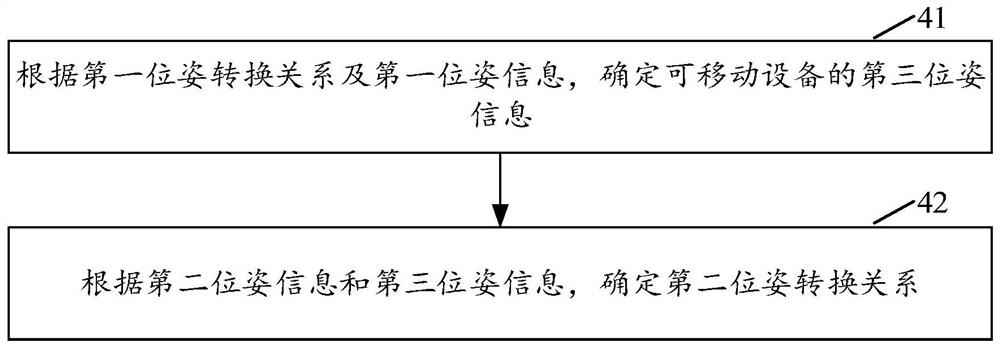

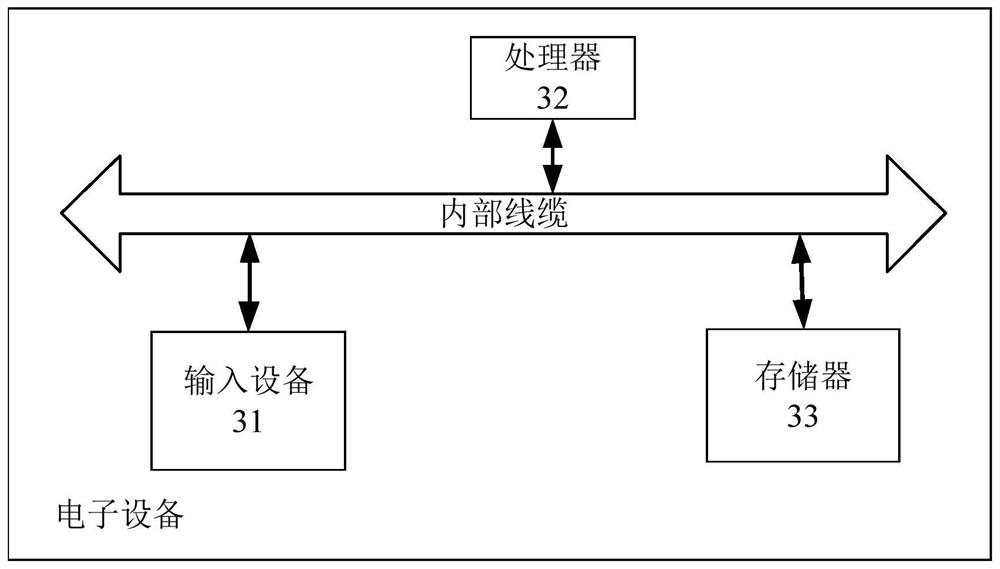

External parameter determination method, external parameter determination device and electronic equipment

The invention discloses an external parameter determination method, an external parameter determination device and electronic equipment. The external parameter determination method comprises the following steps: acquiring first pose information of mobile equipment through a first sensor; acquiring second pose information of the mobile device through a second sensor; obtaining a pre-calibrated first pose conversion relationship between the first sensor and the second sensor; determining a second pose conversion relationship according to the first pose conversion relationship, the first pose information and the second pose information; and determining second external parameter information of the image acquisition equipment according to the second pose conversion relationship and the first external parameter information of the image acquisition equipment, the image acquisition device being installed on the mobile equipment. Compared with an existing external parameter determination method of the image acquisition equipment, the external parameter determination method provided by the embodiment of the invention has the advantages of simple calculation mode, high calculation efficiency and the like, and the purpose of determining the external parameters of the image acquisition equipment in real time can be achieved.

Owner:BEIJING HORIZON ROBOTICS TECH RES & DEV CO LTD

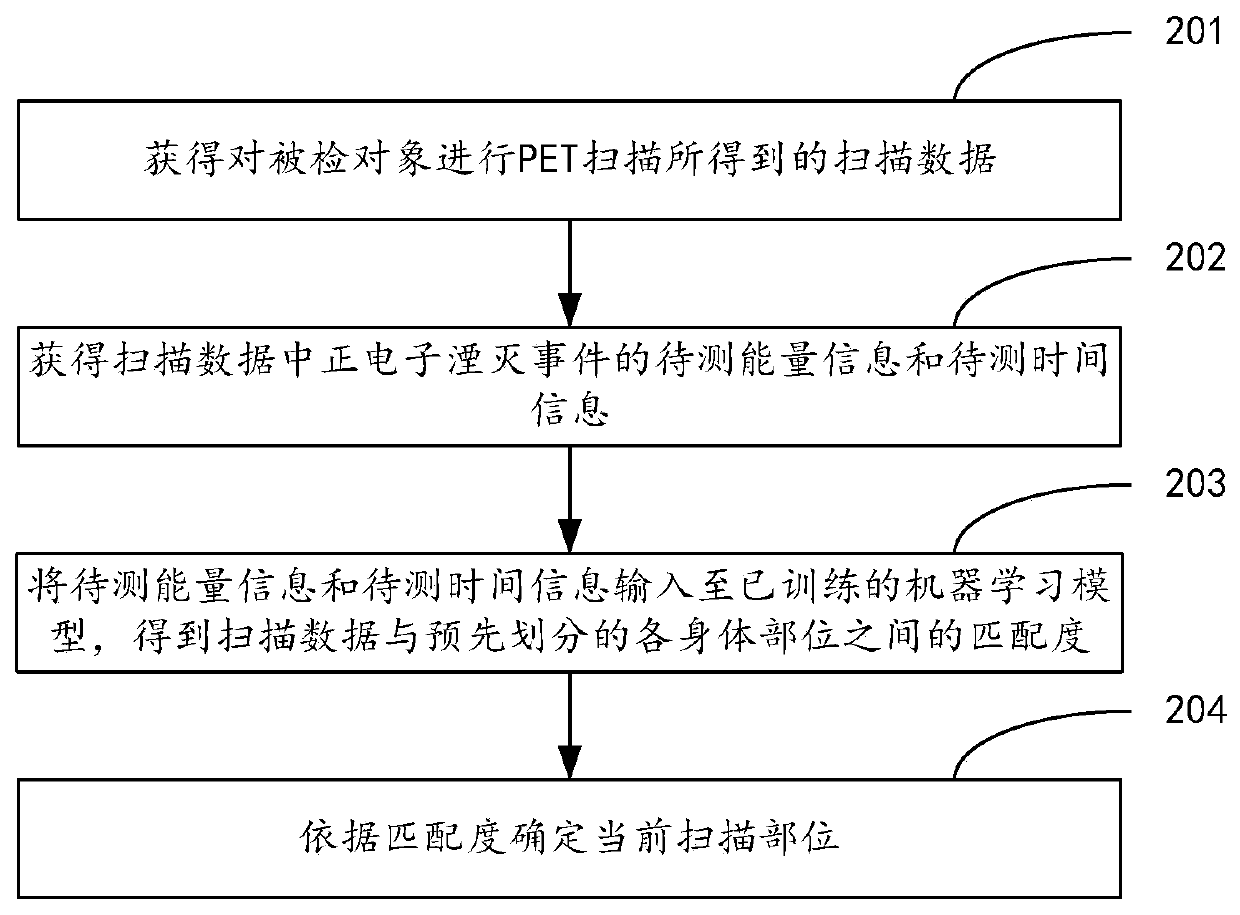

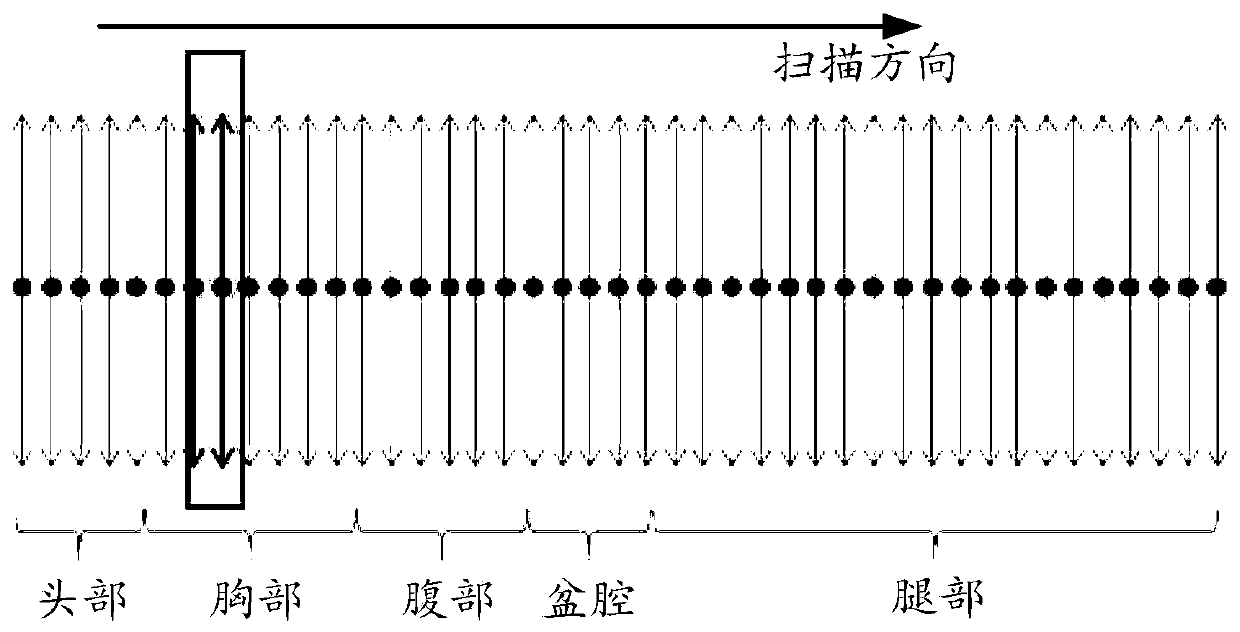

Method and device for determining scanning part and terminal equipment

ActiveCN110313930ARealize OKOK real timeRadiation diagnostic image/data processingNuclear energy generationTime informationBody area

The invention provides a method and device for determining a scanning part and terminal equipment. The method comprises the steps that scanning data obtained by performing PET scanning on a detected object is obtained; to-be-measured energy information and to-be-measured time information of a positron annihilation event in the scanning data are obtained; the to-be-measured energy information and the to-be-measured time information are input to a trained machine learning model to obtain matching degrees between the scanning data and pre-divided body parts; according to the matching degrees, thecurrent scanning part is determined. The method has the advantages that the corresponding body parts can be determined by using the image data of PET itself, and the current scanning part can be determined in real time when PET scanning is performed on the detected object.

Owner:SHENYANG INTELLIGENT NEUCLEAR MEDICAL TECH CO LTD

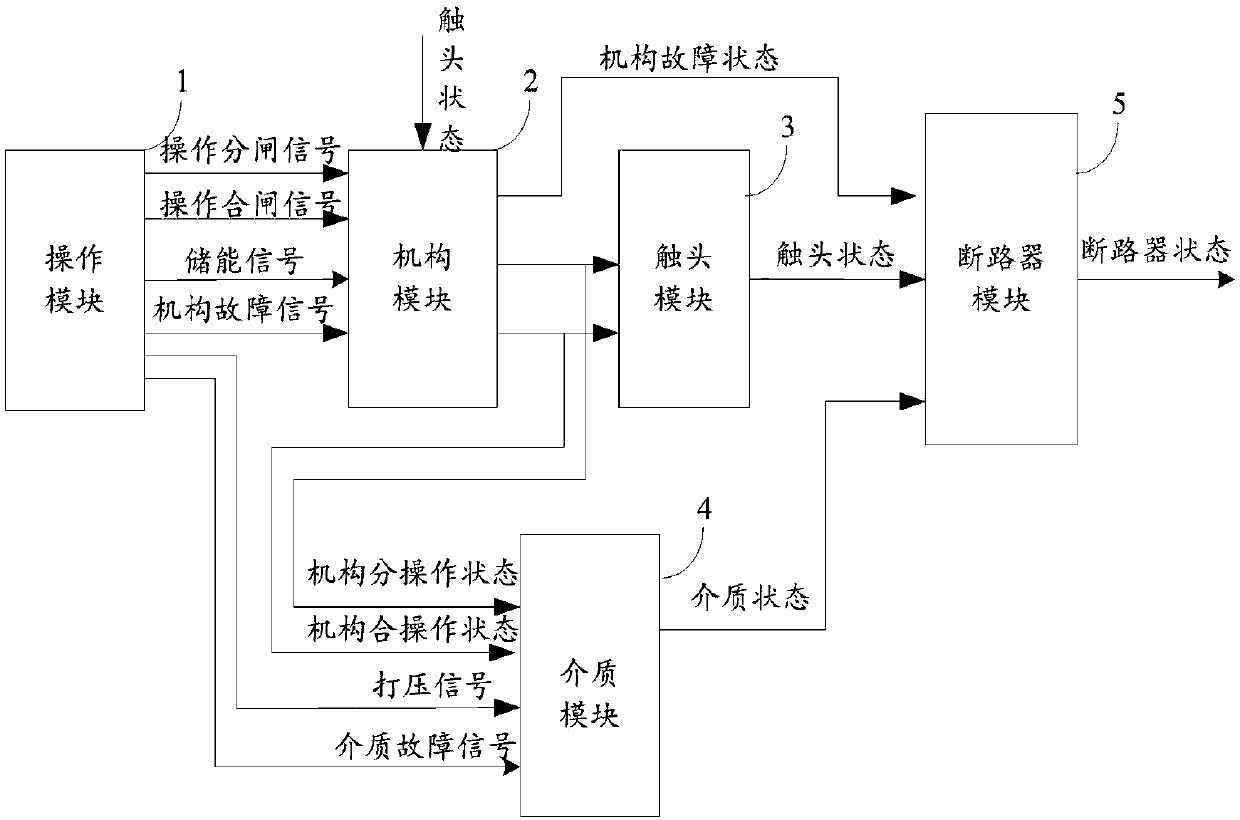

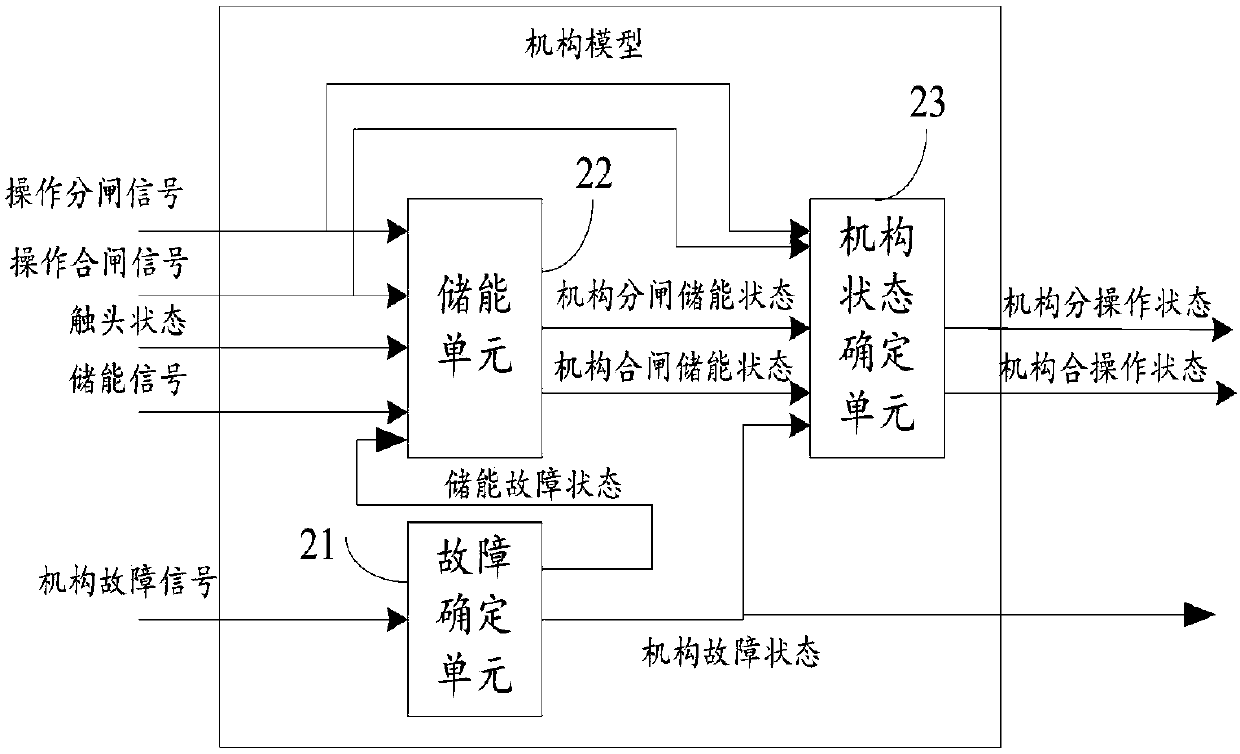

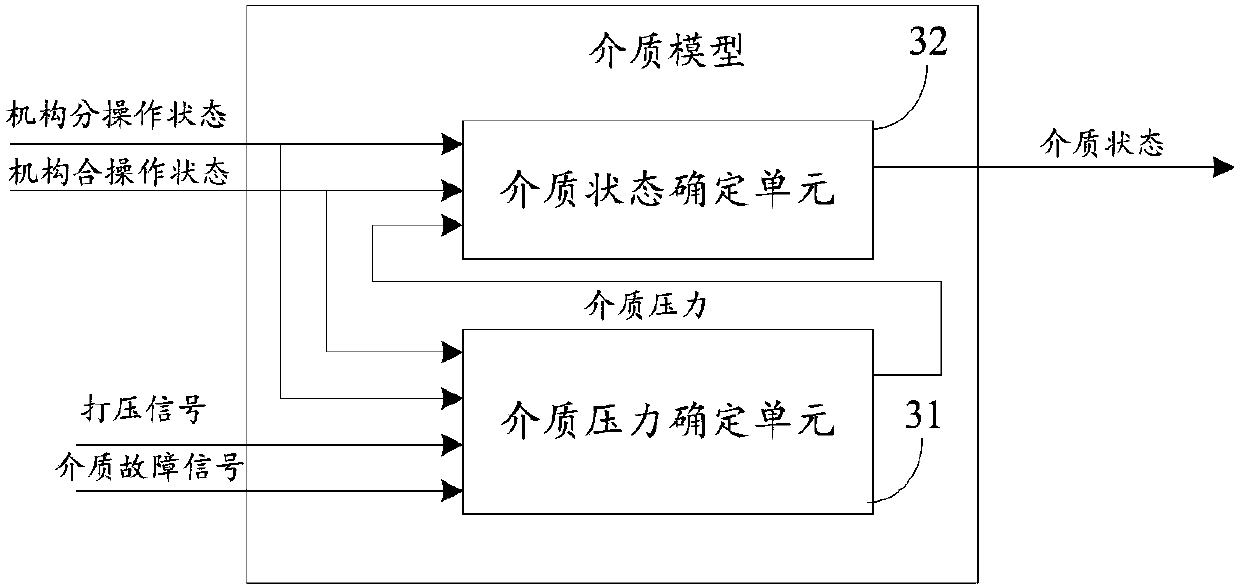

Circuit breaker digital simulation device and method

InactiveCN108039102AEasy and AccurateOK real timeEducational modelsSimulation trainingEnergy storage

The invention discloses a circuit breaker digital simulation device and method. The device comprises an operation module which generates an operation opening signal, an operation closing signal, an energy storage signal, a mechanism failure signal, a medium fault signal, and a pressing signal; a mechanism module which is used for determining the mechanism sub-operating state, the mechanism combined operating state, and the mechanism fault state according to the operation opening signal, the operation closing signal, the energy storage signal, the mechanism failure signal, and the contact state; a contact module which is used for determining the contact state according to the mechanism sub-operating state and the mechanism combined operating state; a medium module which is used for determining the medium state based on the medium failure signal and the pressing signal, the mechanism sub-operating state and the mechanism combined operating state; and a circuit breaker module which is used for determining the circuit breaker state according to the mechanism failure state, the contact state and the medium state. The working process of the circuit breaker is simply and accurately described in real time in the simulation training, and the problems that a traditional simulation result is easy to dissipate, and the real-time performance is difficult to meet the requirements are solved.

Owner:CHINA THREE GORGES UNIV

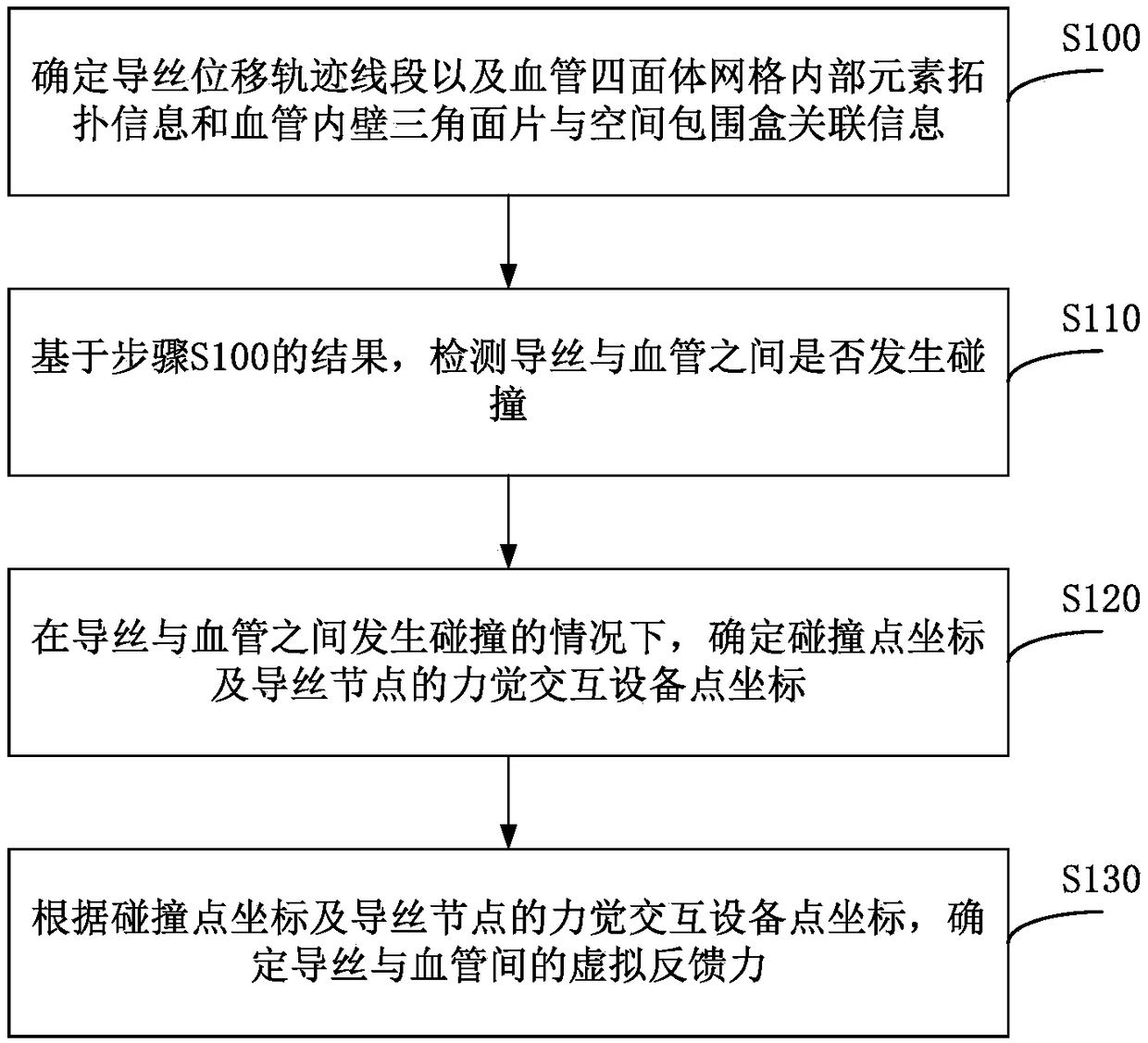

Method and system for determining feedback force in virtual cardiovascular interventional surgery training system

The invention discloses a method and system for determining a feedback force in a virtual cardiovascular interventional operation training system. The method includes the following steps that: displacement trajectory segments of a guide wire, topologic information of inner elements of the tetrahedral meshes of a blood vessel, and associated information of the triangular patches of the inner wall of the blood vessel and a space bounding box are obtained; based on the above results, whether the guide wire and the blood vessel collide is judged; if the guide wire and the blood vessel collide, the coordinates of a collision point and the coordinates of a force sense interaction device of a guide wire node are determined; and a virtual feedback force between the guide wire and the blood vessel is determined according to the coordinates of the collision point and the coordinates of the force sense interaction device of the guide wire node. With the method and system provided by the embodiments of the invention adopted, technical problems in accurately determining a virtual feedback force between a guide wire and a blood vessel in real time can be solved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

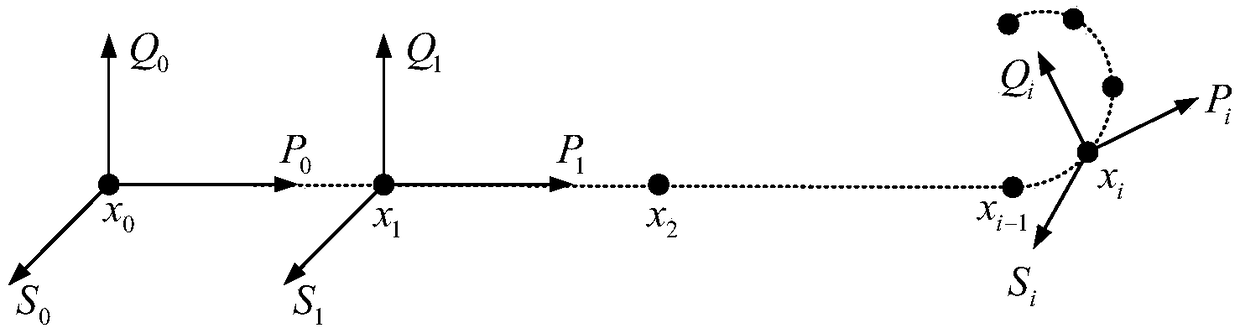

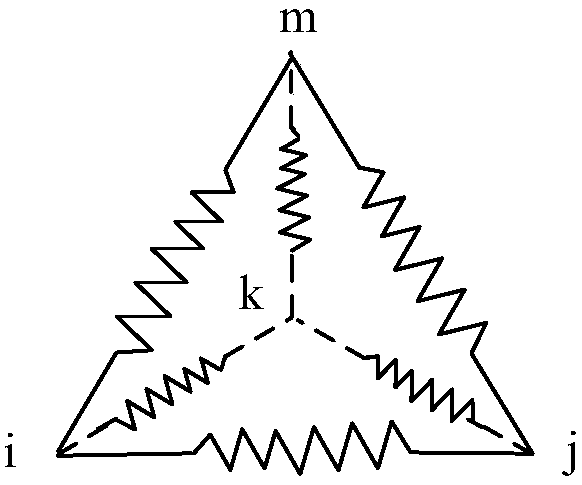

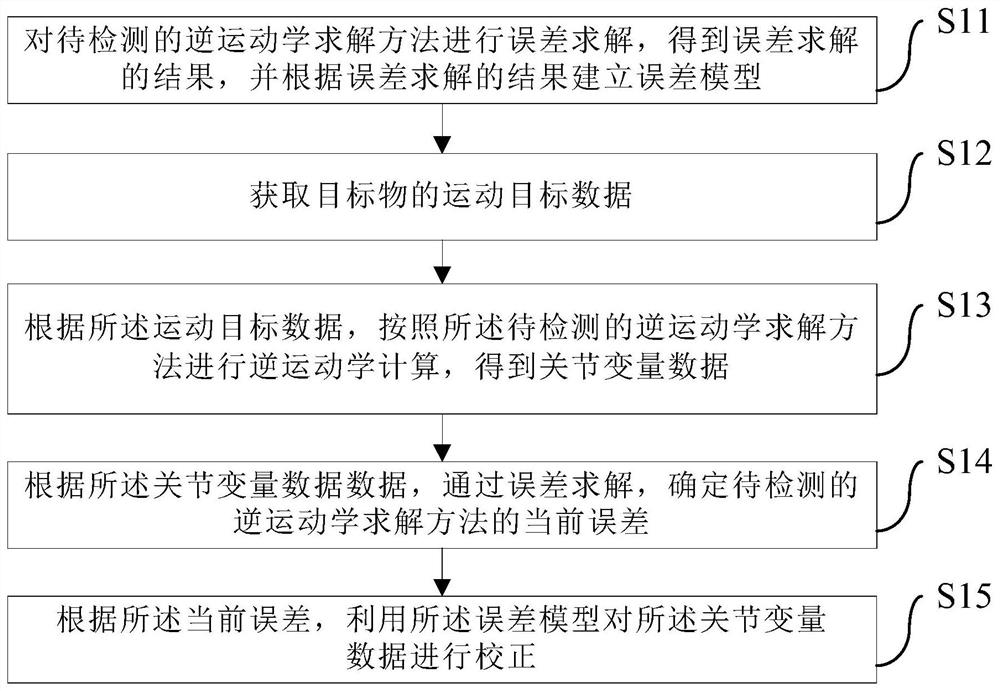

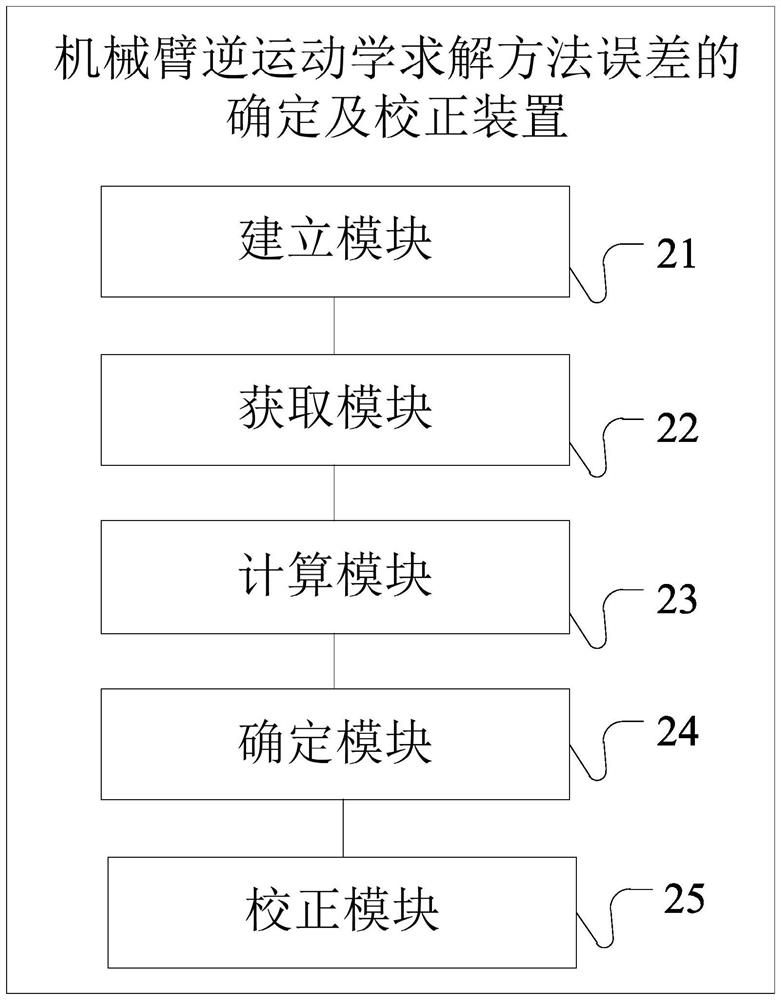

Method and device for determining and correcting error of inverse kinematics solution method of manipulator

ActiveCN107553496BReal-time correctionOK real timeProgramme-controlled manipulatorAlgorithmData error

Owner:NANJING AVATARMIND ROBOT TECH CO LTD

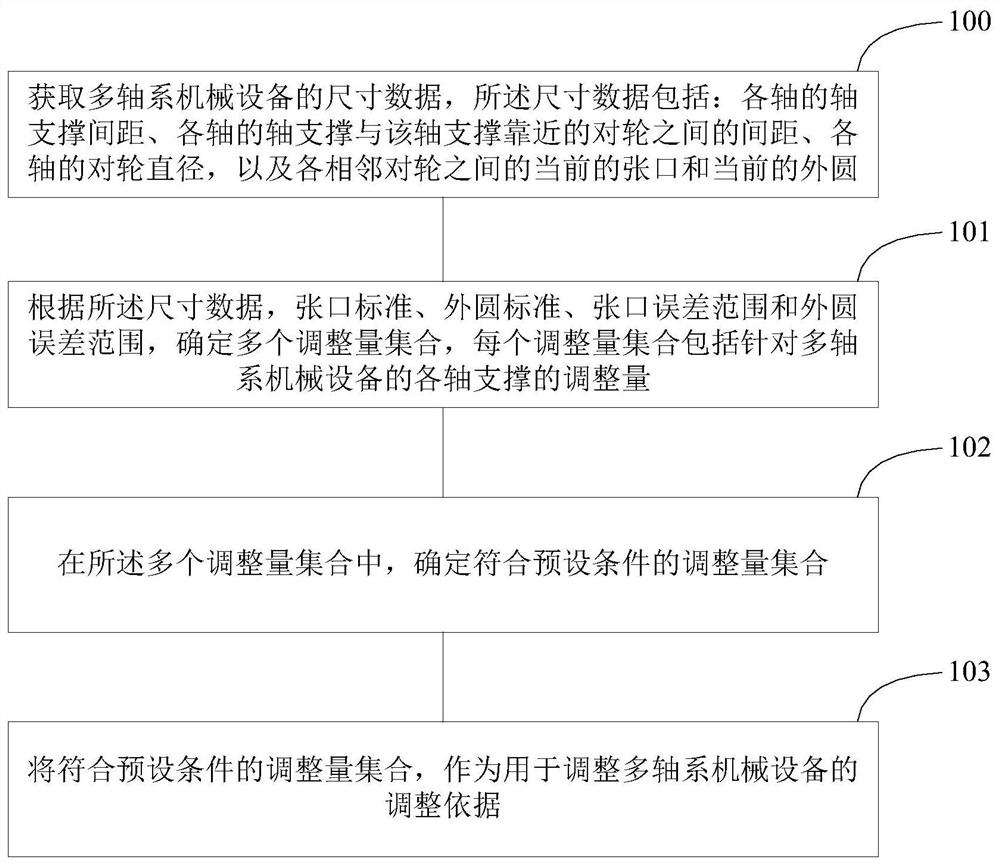

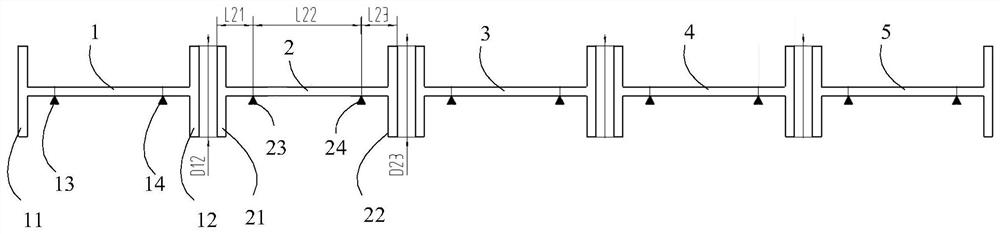

Center adjusting method and device for multi-shafting mechanical equipment

ActiveCN111693014AOK real timeAccurately determineMeasurement devicesComplex mathematical operationsNuclear powerProcess engineering

The invention belongs to the technical field of nuclear power maintenance, and particularly relates to a center adjusting method and device for multi-shafting mechanical equipment. According to the embodiment of the invention, through collecting the size data of the multi-shafting mechanical equipment, depending on size data, opening error range and excircle error range, the multiple adjustment amount sets are determined, and the adjustment amount set meeting the preset condition is determined from the multiple adjustment amount sets and serves as the adjustment parameter for adjusting the multi-axis mechanical equipment, so that the optimal scheme capable of meeting the field error condition can be accurately determined in real time, and the equipment adjustment efficiency is improved.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

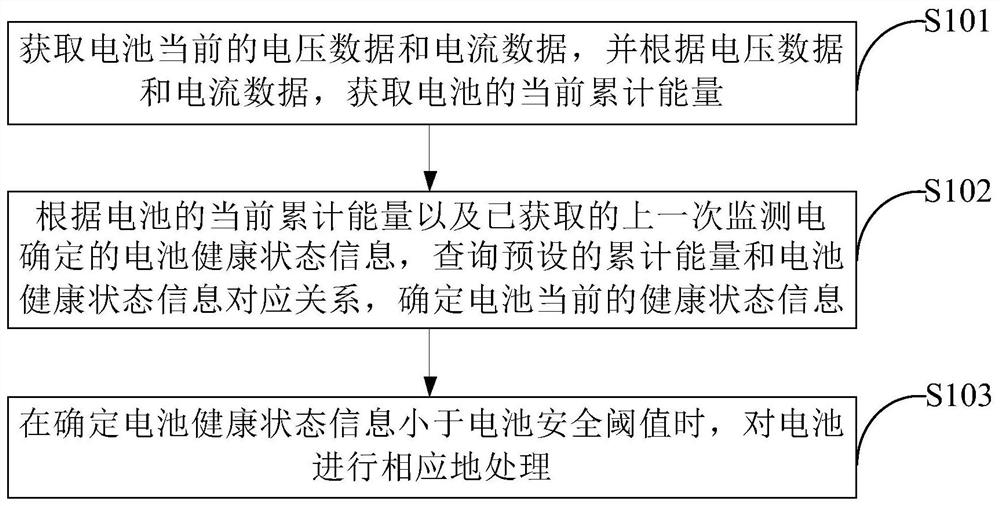

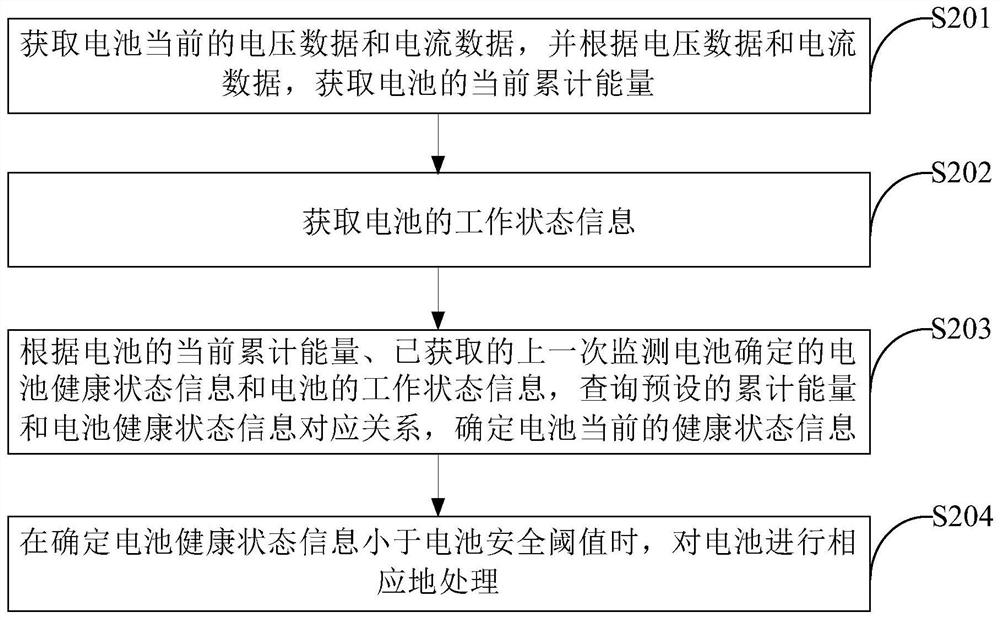

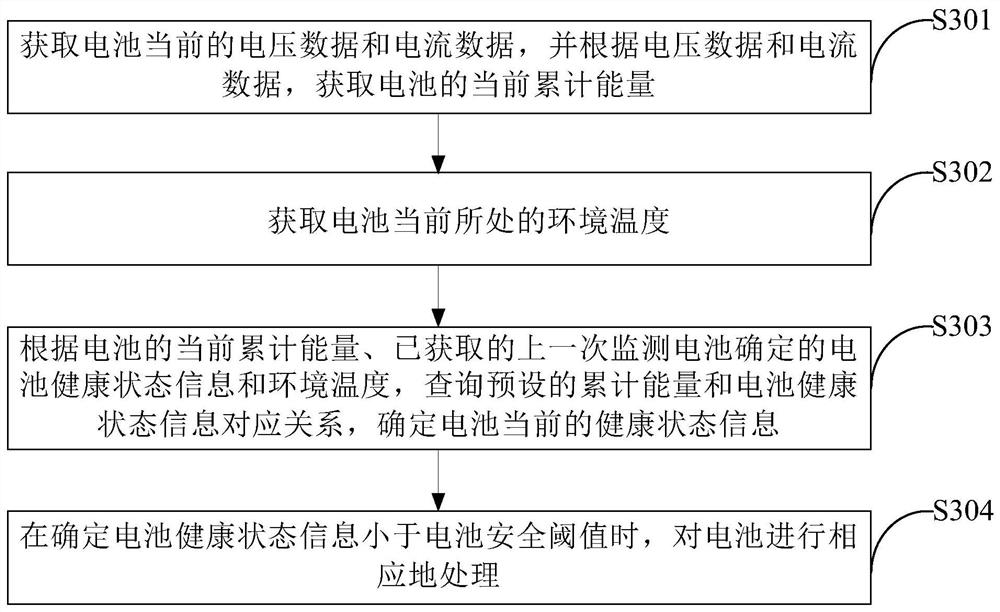

Processing method and device based on battery, electronic equipment and storage medium

The invention provides a processing method and device based on a battery, electronic equipment and a storage medium, and the method comprises the steps: obtaining the current accumulated energy of the battery and the battery health state information determined by monitoring the battery last time, and according to the current accumulated energy of the battery and the battery health state information determined by monitoring the battery last time, querying a preset corresponding relationship between the accumulated energy and the battery health state information, determining the current health state information of the battery, and performing corresponding processing on the battery when determining that the health state information of the battery is smaller than a battery safety threshold value. By inquiring the corresponding relation between the accumulated energy of the battery and the health state information of the battery, the health state information of the battery can be accurately calculated and monitored in real time, so that the battery can be correspondingly processed more timely when the health state of the battery is smaller than a safety threshold value.

Owner:BEIJING HYPERSTRONG TECH

Processing method and device

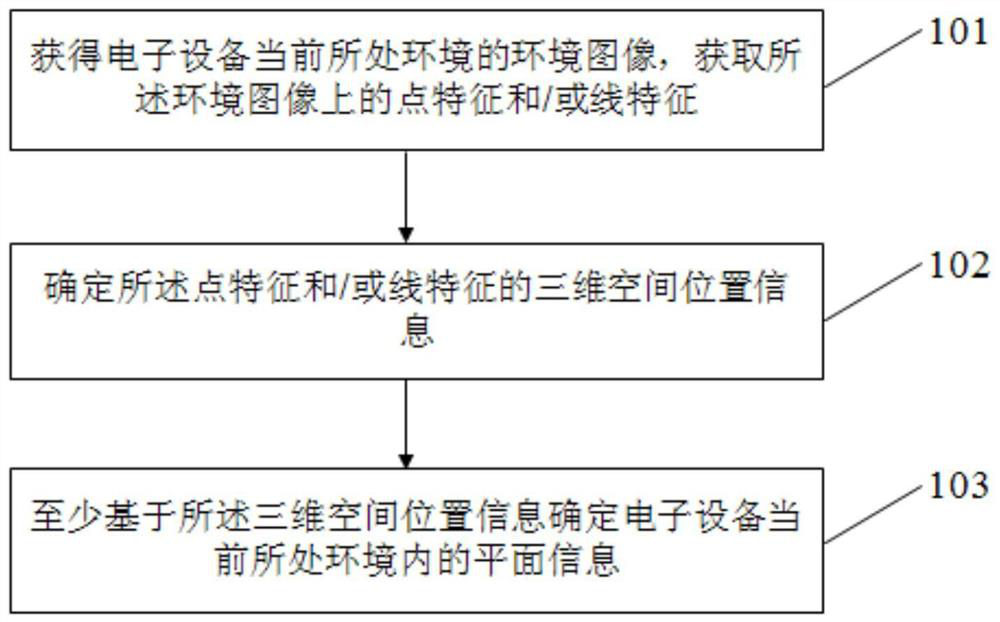

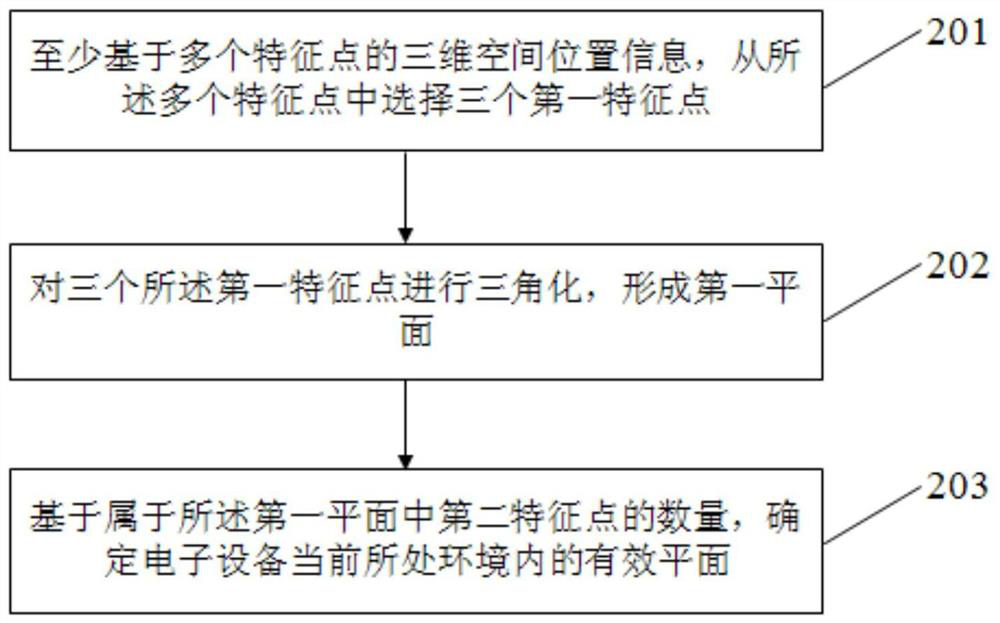

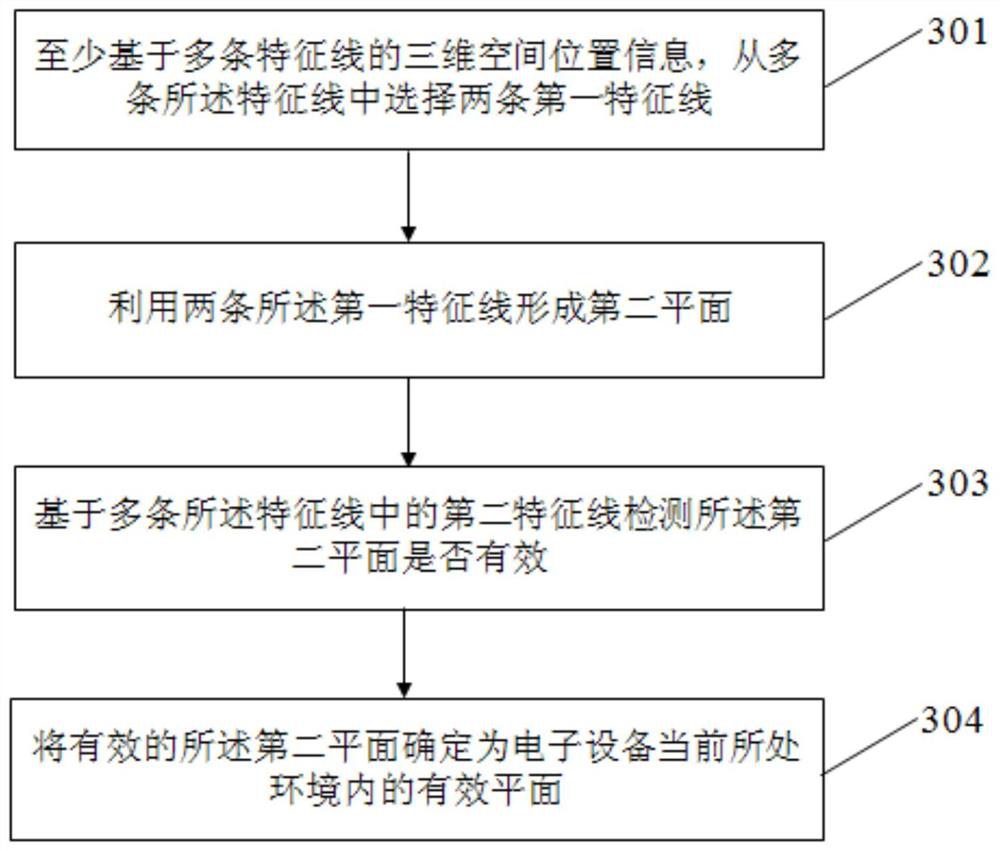

PendingCN113052977AAccurately determineOK real time3D modellingView cameraComputer graphics (images)

The invention relates to a processing method and device, and the method comprises the following steps:obtaining an environment image of an environment where electronic equipment is located at present, and obtaining point features and / or line features on the environment image; determining three-dimensional space position information of the point features and / or the line features; and determining plane information in the current environment of the electronic equipment at least based on the three-dimensional space position information. The processing method provided by the embodiment of the invention can accurately and comprehensively detect the plane information in the current environment of the electronic equipment without depending on a depth camera, and is wide in application range and relatively low in cost. According to the method, the plane information in the current environment of the electronic equipment can be determined by adopting a universal monocular or multi-view camera, the operation is convenient, a depth camera does not need to be used, and the universality is high; and meanwhile, the plane information of the current environment of the electronic equipment can be accurately and comprehensively detected, the plane information can also be accurately determined in the environment with few textures, and good robustness is achieved.

Owner:LENOVO (BEIJING) LTD

Method for determining temperature-dependent performance of a friction clutch

InactiveCN106015377BFriction power determination or estimationOK real timeMachine part testingFriction clutchesEngineeringClutch

The invention relates to a method for determining the temperature-dependent behavior of a friction clutch having at least two disks carrying friction surfaces in the form of at least one counter pressure disk and at least one pressure disk, wherein The temperature model estimates the clutch temperature at least by means of energy input into the friction clutch. In order to further improve the temperature dependence of the function of the friction clutch, the temperature-dependent friction power is determined from the temperature estimated from the temperature model and from the properties of the geometry of the at least two disks.

Owner:SCHAEFFLER TECH AG & CO KG

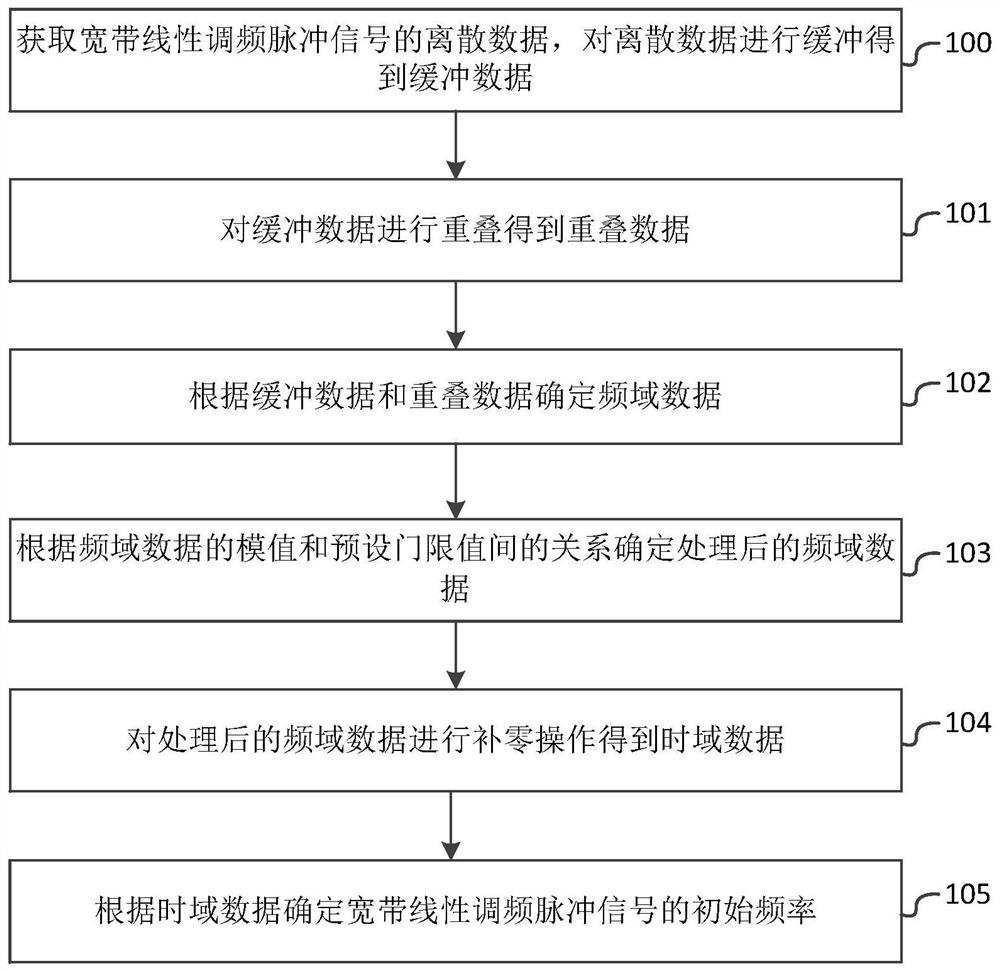

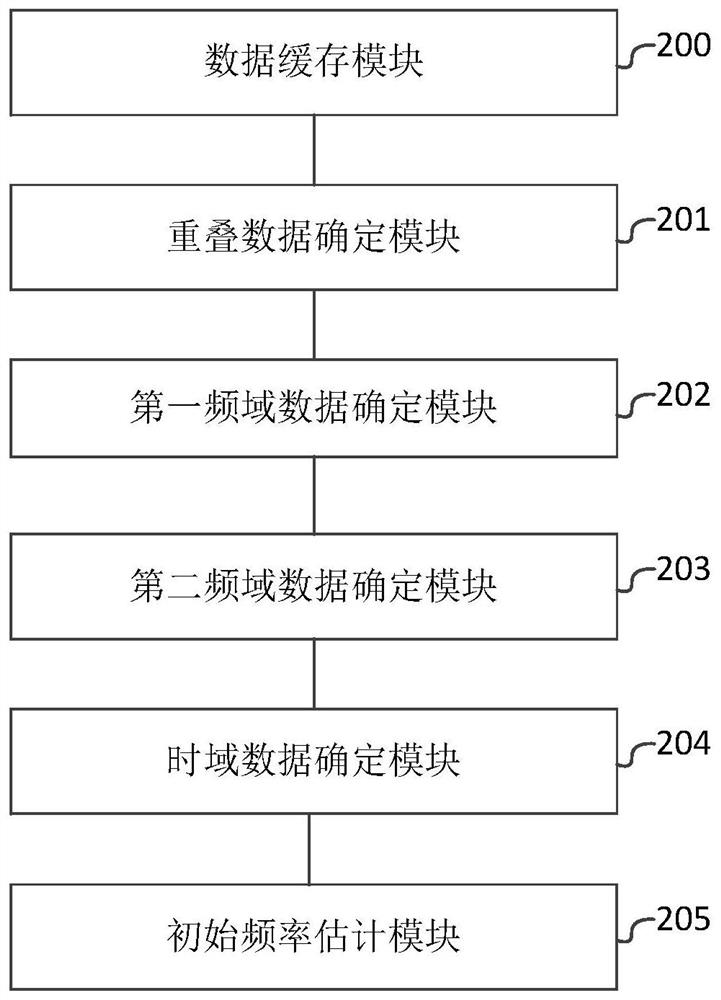

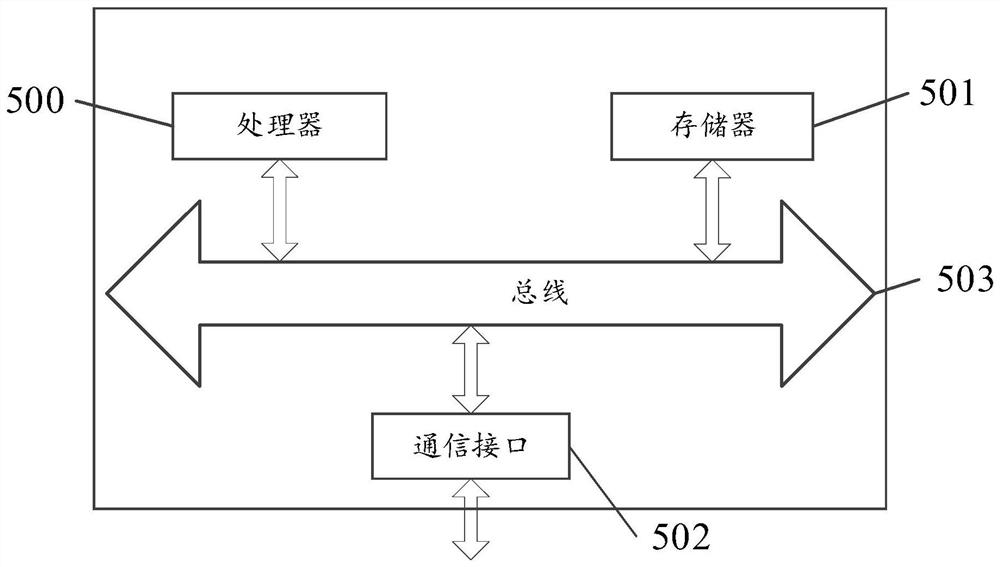

Method and system for determining initial frequency of broadband linear frequency modulation pulse signal

The invention discloses a broadband linear frequency modulation pulse signal initial frequency determination method and system. According to the method for determining the initial frequency of the broadband linear frequency modulation pulse signal, after discrete data of the broadband linear frequency modulation pulse signal are obtained, the discrete data are buffered to obtain buffered data, a continuous pulse signal can be converted into the discrete signal, after the cached data are preprocessed to obtain time domain data, under the condition that the center frequency of the broadband linear frequency modulation pulse signal is known and the frequency modulation slope is unknown, the initial frequency of the broadband linear frequency modulation pulse signal can be determined in real time according to the time domain data, and then problems that a common linear frequency modulation pulse signal initial frequency estimation method is large in calculation amount and cannot process in real time are solved.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

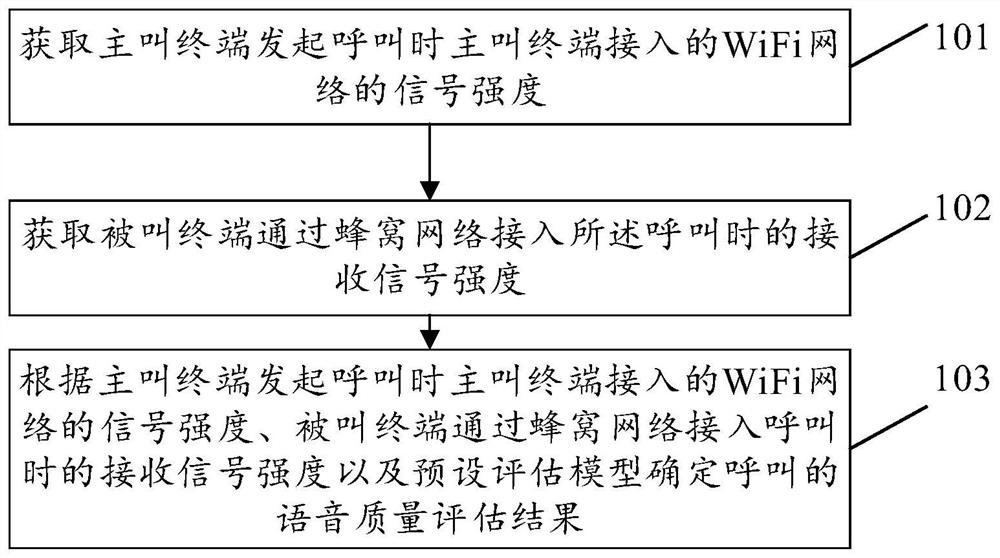

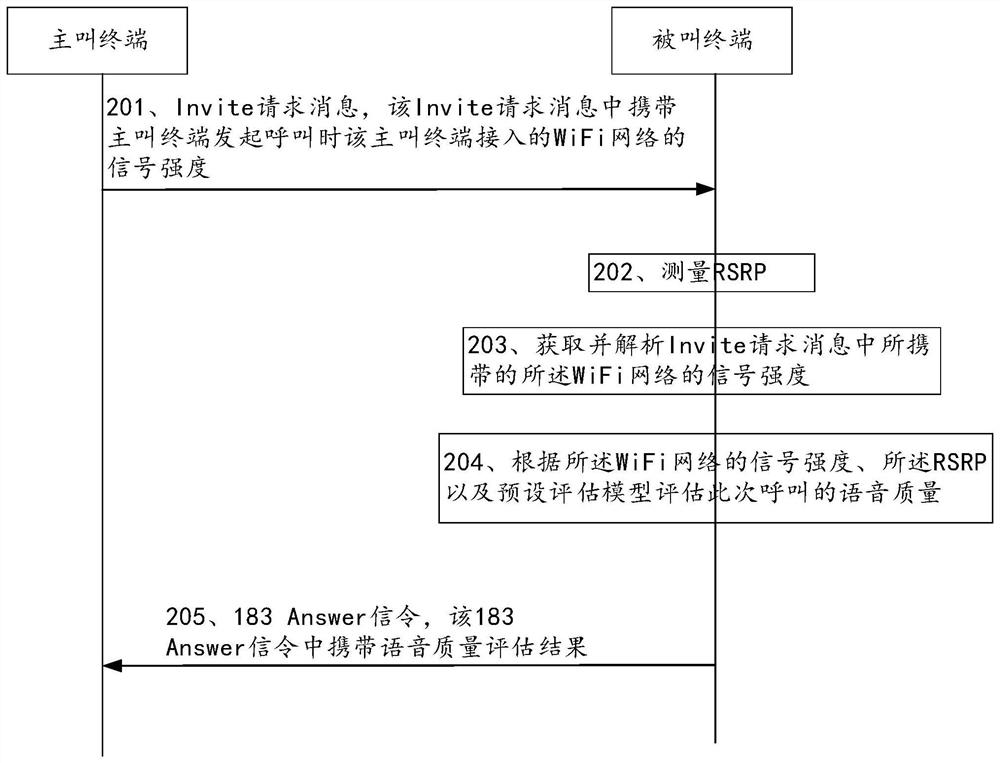

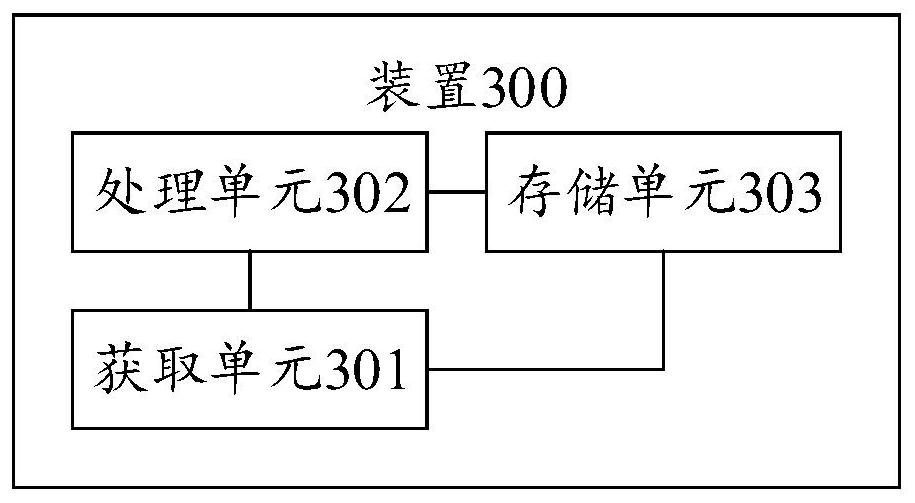

Speech quality assessment method and device

ActiveCN108882291BOK real timeImprove accuracySpeech analysisTransmission monitoringAccess networkEvaluation result

The embodiment of the present application discloses a voice quality assessment method, which relates to the field of communication technology and is invented to solve the problems existing in the prior art that the voice quality of the network cannot be assessed in real time and the accuracy of the assessment result is poor. The method is applied in a VoWiFi scenario. In a VoWiFi scenario, a calling terminal accesses a WiFi network and initiates a call through the WiFi network, and a called terminal accesses a call through a cellular network. The method includes: acquiring the signal strength of the WiFi network accessed by the calling terminal when the calling terminal initiates a call. Obtain the received signal strength when the called terminal accesses the call through the cellular network. The voice quality evaluation result of the call is determined according to the signal strength of the WiFi network accessed by the calling terminal when the calling terminal initiates the call, the received signal strength when the called terminal accesses the call through the cellular network, and a preset evaluation model.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

Thin and narrow groove detection device and method of strong specular reflection workpiece based on strip light source

The invention provides a strong specular reflection workpiece thin and narrow groove detection device and method based on strip-shaped light sources, and belongs to the field of welding automation. According to the device and the method, a strip-shaped light source array irradiates the surface of a workpiece so that a workpiece surface image with the uniform gray level can be obtained, and the automatic detection on a strong specular reflection workpiece thin and narrow groove is achieved by determining the relative position and the posture between a welding gun and the workpiece through a laser array. According to the device and the method, the strip-shaped light source array irradiates the surface of the strong specular reflection workpiece so that the uniform-illumination workpiece surface image can be obtained, the characteristics of the groove in the image are obvious, the center position of the groove is conveniently and accurately extracted, and the detection accuracy can reach 0.03 mm; the relative position and the posture between the workpiece and the welding gun can be rapidly and accurately obtained through the laser array; the system structure is simple, the detection accuracy is high, instantaneity is high, cost is low, and the strong specular reflection workpiece thin and narrow groove detection device and method can be applied to automatic detection of the groove of the strong specular reflection workpiece surface and are particularly suitable for the occasion of high-energy beam welding automatic tracking of the thin and narrow groove workpiece with the groove gap smaller than 0.1 mm.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com