Thin and narrow groove detection device and method of strong specular reflection workpiece based on spherical light source

A spherical light source and specular reflection technology, which is used in measuring devices, optical devices, manufacturing tools, etc., can solve the problems of difficulty in accurately determining the relative position and orientation of the welding torch and the workpiece, uneven image grayscale, and limited detection accuracy. Low cost, uniform image grayscale, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

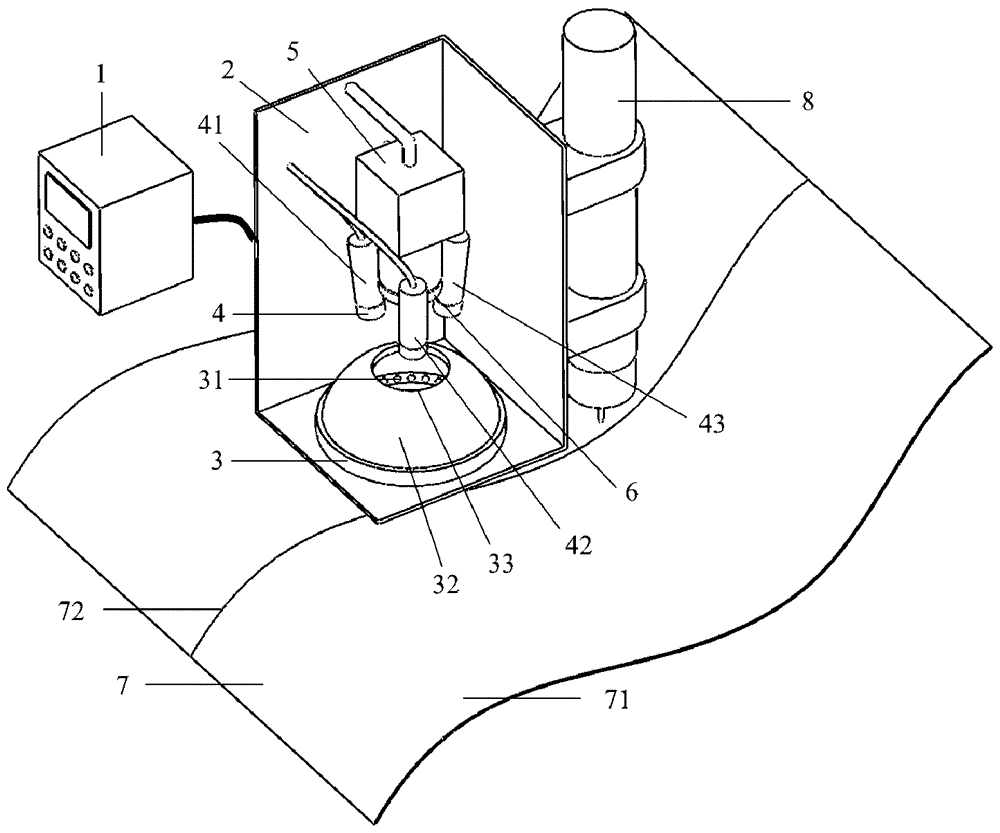

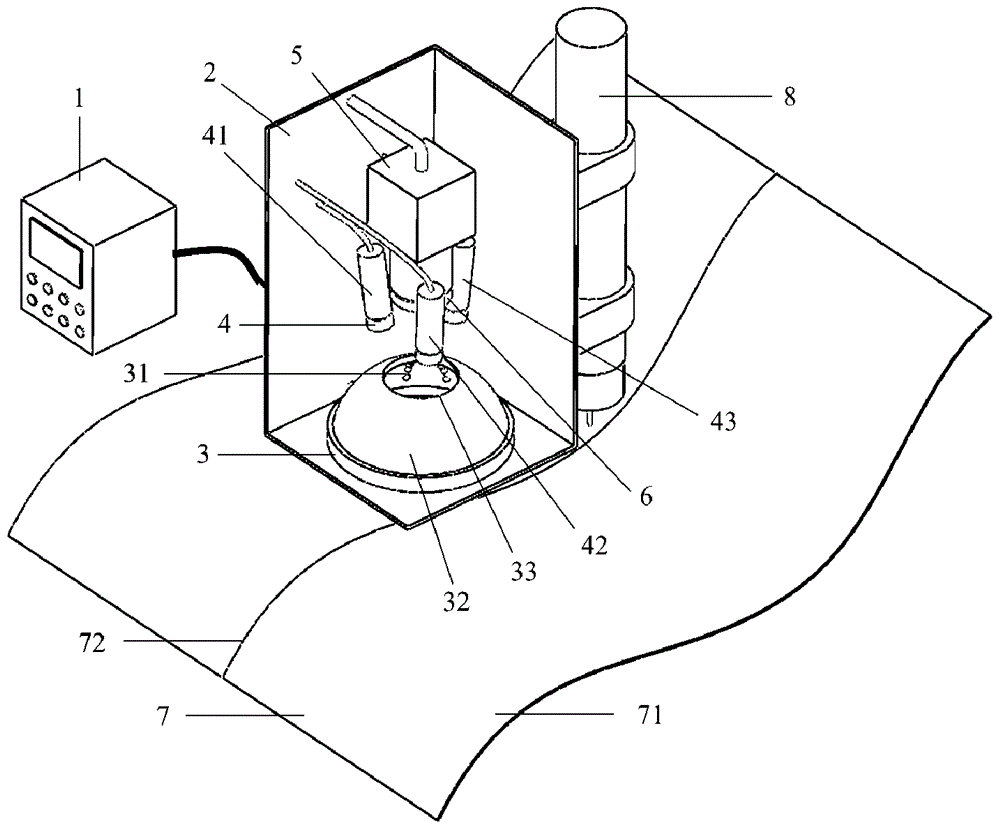

[0040] figure 1 It is a schematic diagram of the structure principle of the first embodiment of the device and method for detecting thin and narrow grooves of workpieces with strong specular reflection based on spherical light sources proposed by the present invention, including a control unit 1, a sensor housing 2, a spherical light source 3, a laser array 4, and an imaging element 5 and filter element 6. The control unit 1 is connected to the spherical light source 3, the laser array 4 and the imaging element 5 through wires; the control unit 1 sends a trigger signal to make the spherical light source 3 and the laser array 4 flash alternately, and the imaging element 5 is synchronized Collect surface images of the workpiece 7 illuminated by different light sources; the sensor housing 2 is consolidated with the welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com