Center adjusting method and device for multi-shafting mechanical equipment

A technology of mechanical equipment and center adjustment, which is applied in the direction of measuring devices, complex mathematical operations, instruments, etc., can solve the problems of small adjustable amount, on-site progress delay, low efficiency, etc., and achieve the effect of improving adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

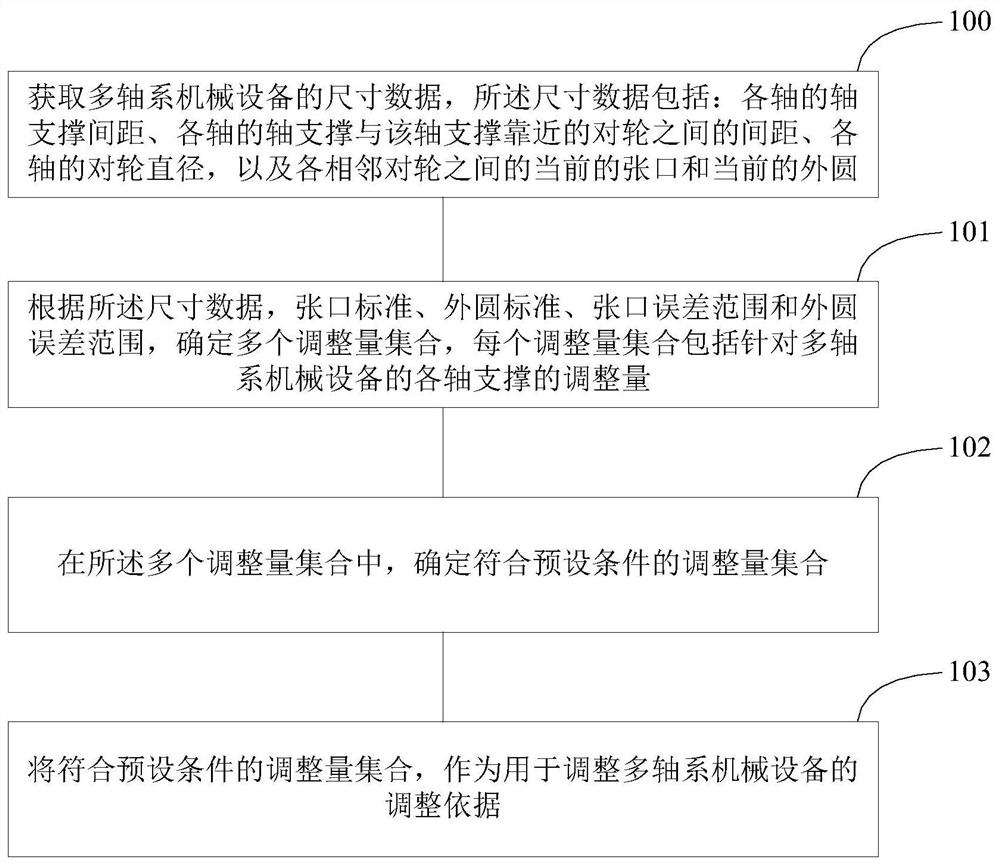

[0045] figure 1 It is a flow chart of a center adjustment method for multi-shaft mechanical equipment according to an exemplary embodiment. The method may be applied, for example, to a control device such as a notebook, a desktop computer, or a server, and the embodiment of the present disclosure does not limit the type of the control device. Such as figure 1 As shown, the method may include:

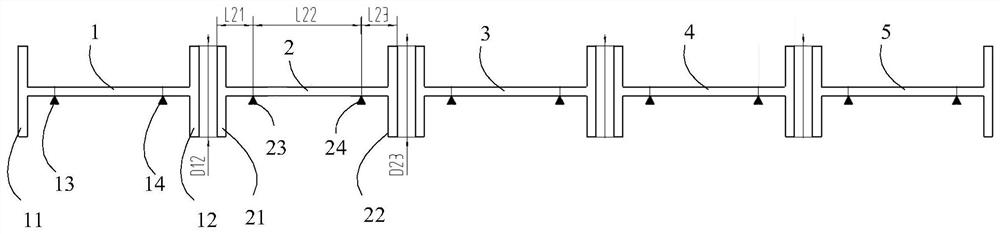

[0046] Step 100, obtain the dimensional data of the multi-shaft mechanical equipment, the dimensional data includes: the distance between the shaft supports of each shaft, the distance between the shaft support of each shaft and the opposite wheel close to the shaft support, and the diameter of the opposite wheel of each shaft , and the current opening and current outer circle between adjacent pairs of wheels;

[0047] Step 101, according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com