Three-dimensional measuring support

A three-coordinate measurement, consistent technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to realize the full-scale three-coordinate measurement of parts, increase the workload of programming and measurement personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

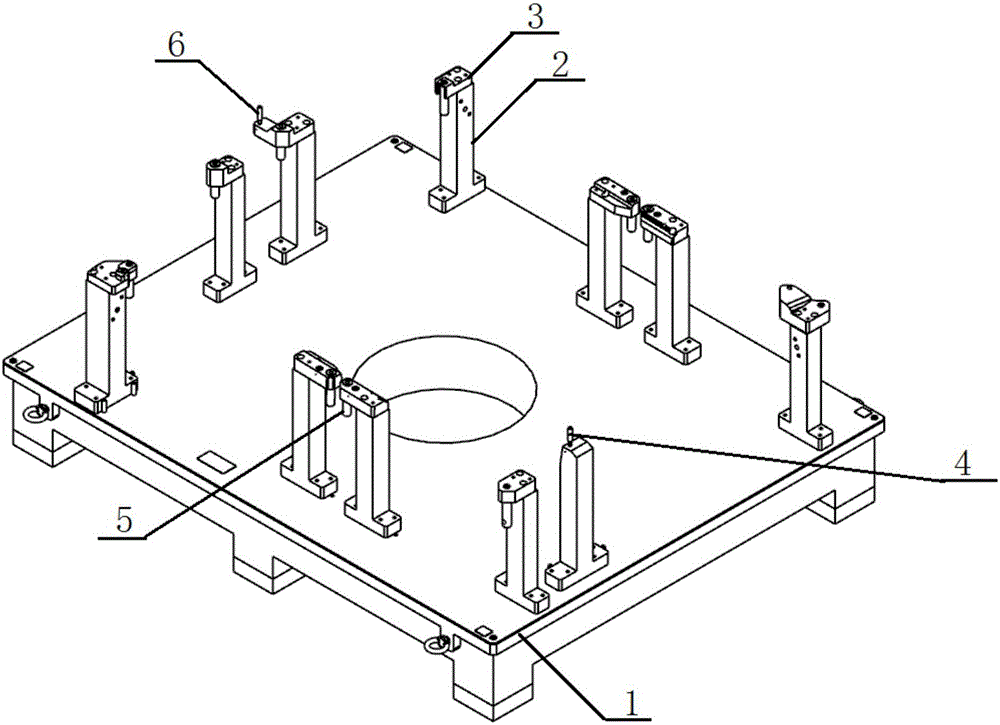

[0017] Such as figure 1 As shown, a three-coordinate measurement support includes a base plate 1 and a support column 2, and the support columns 2 are provided with at least three, and a plurality of the support columns 2 are vertically distributed and fixed on the base plate 1, and the support columns 2 The quantity and the position of the distribution on the bottom plate 1 are determined according to the structure of the part to be tested itself. A fixed block 3 is respectively installed on the top of each of the support columns 2, and one of the fixed blocks 3 is provided with a Y To the locating pin 4, the other fixed block 3 is provided with a XY locating pin 6, remove the Y locating pin 4 or the rest of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com