A Degraded Reliability Analysis Method Considering Measurement Error

A technology for measuring errors and analysis methods, applied in instruments, geometric CAD, calculations, etc., to solve problems such as processing, degraded data reliability theory and methods are not perfect

- Summary

- Abstract

- Description

- Claims

- Application Information

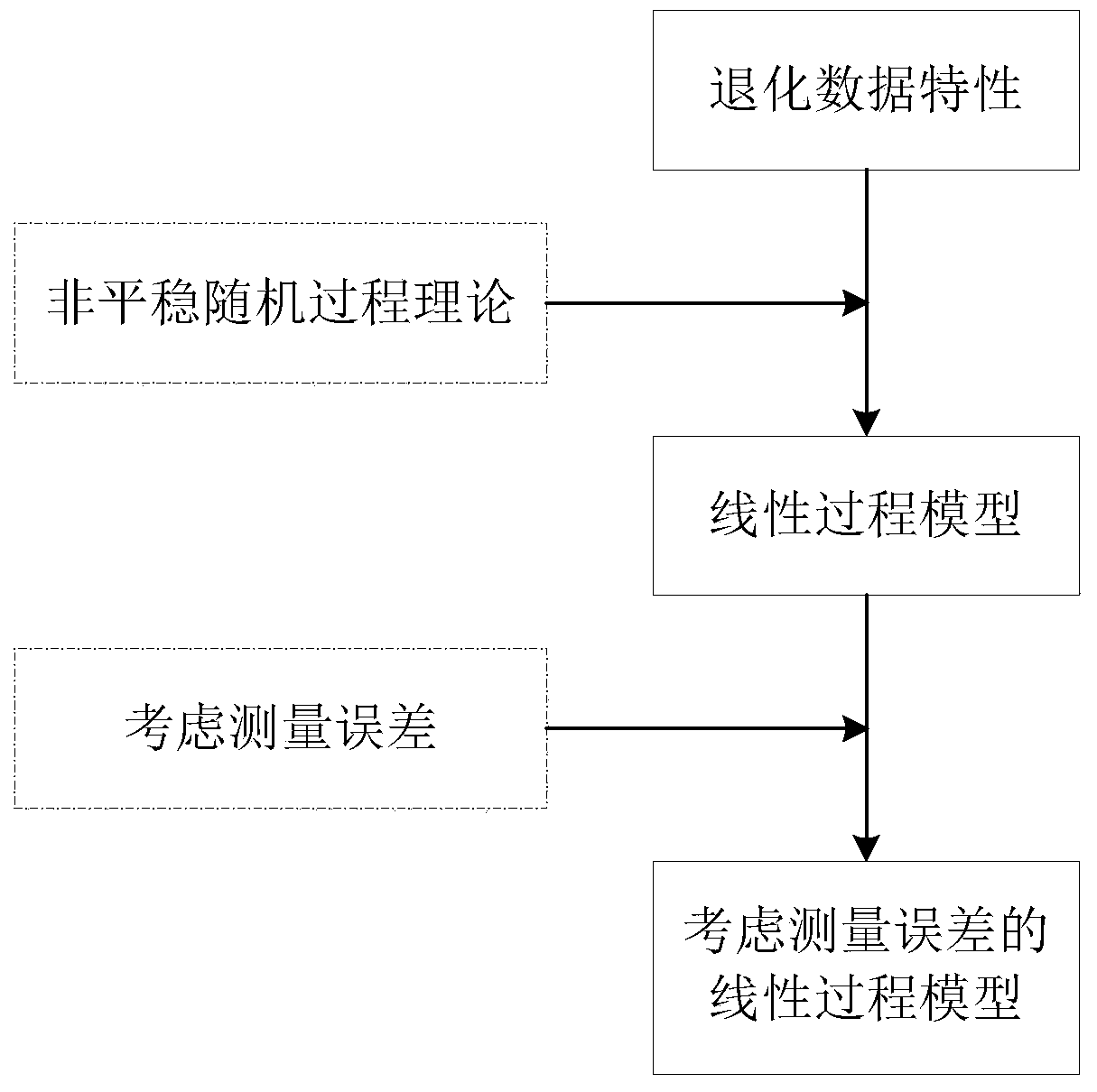

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in detail below in conjunction with specific data.

[0068] The present invention proposes a degradation reliability analysis method based on small sample reliability and non-stationary random process theory, which is specifically divided into the following steps:

[0069] Step 1: Select the appropriate degeneration parameters, so that it can be converted into a linear independent incremental process through appropriate transformation, record the ith specimen at time t j The performance degradation measure for z ij , i=1,2,...,m, j=1,2,...,n;

[0070] Among them, the selection of degradation parameters is carried out based on physical failure analysis.

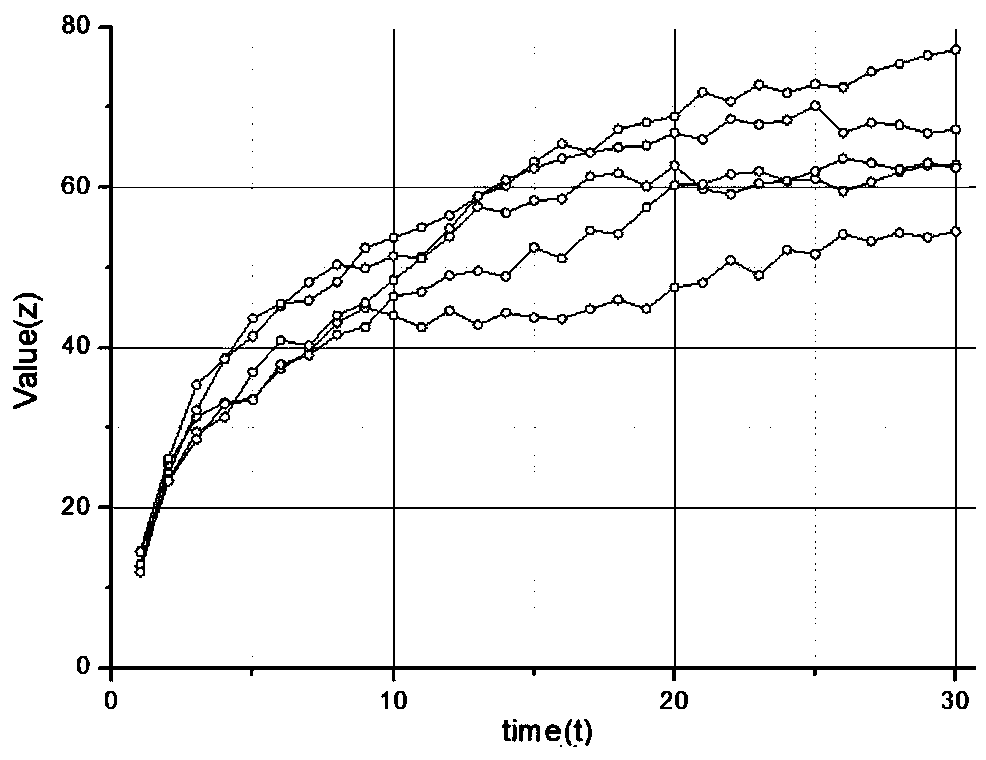

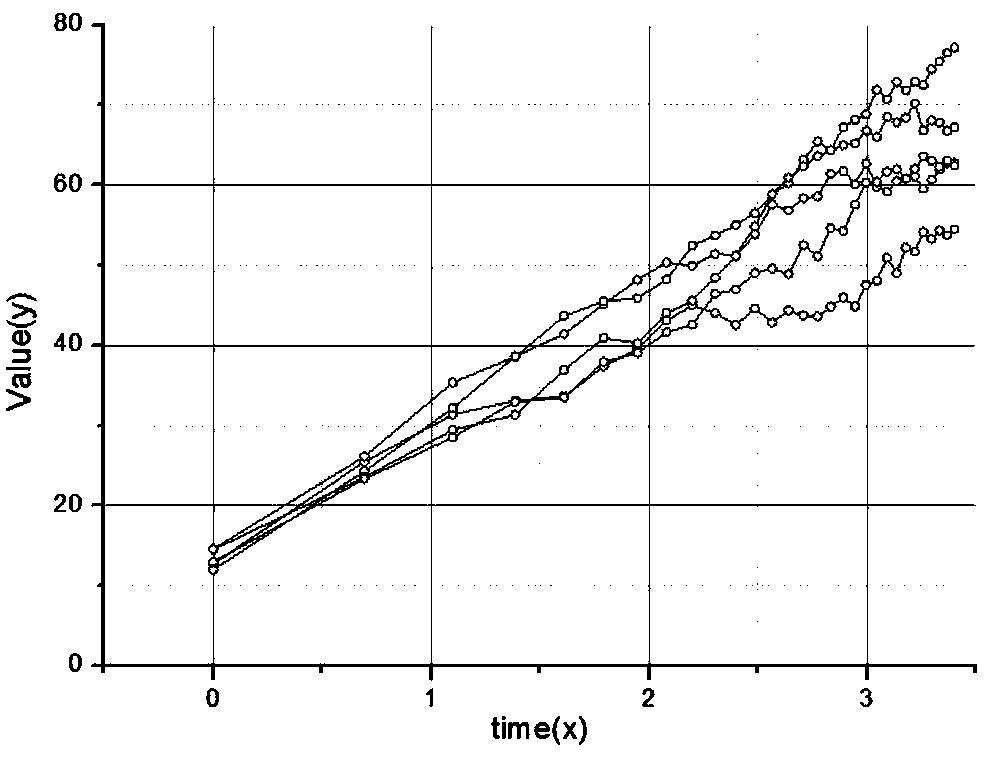

[0071] After determining the degradation parameters, the present invention takes a set of engineering measured data as an example, with a total of 30 test moments and 5 samples, such as Figure 2a shown. It is transformed x=ln t, y=z, the transformed x-y curve is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com