Mean-line-based blade front and back edge fitting and section line smooth reconstruction method

A section line, leading and trailing edge technology, applied in the field of blade leading and trailing edge fitting based on the mid-arc line and smooth reconstruction of section lines, can solve the problems of poor practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

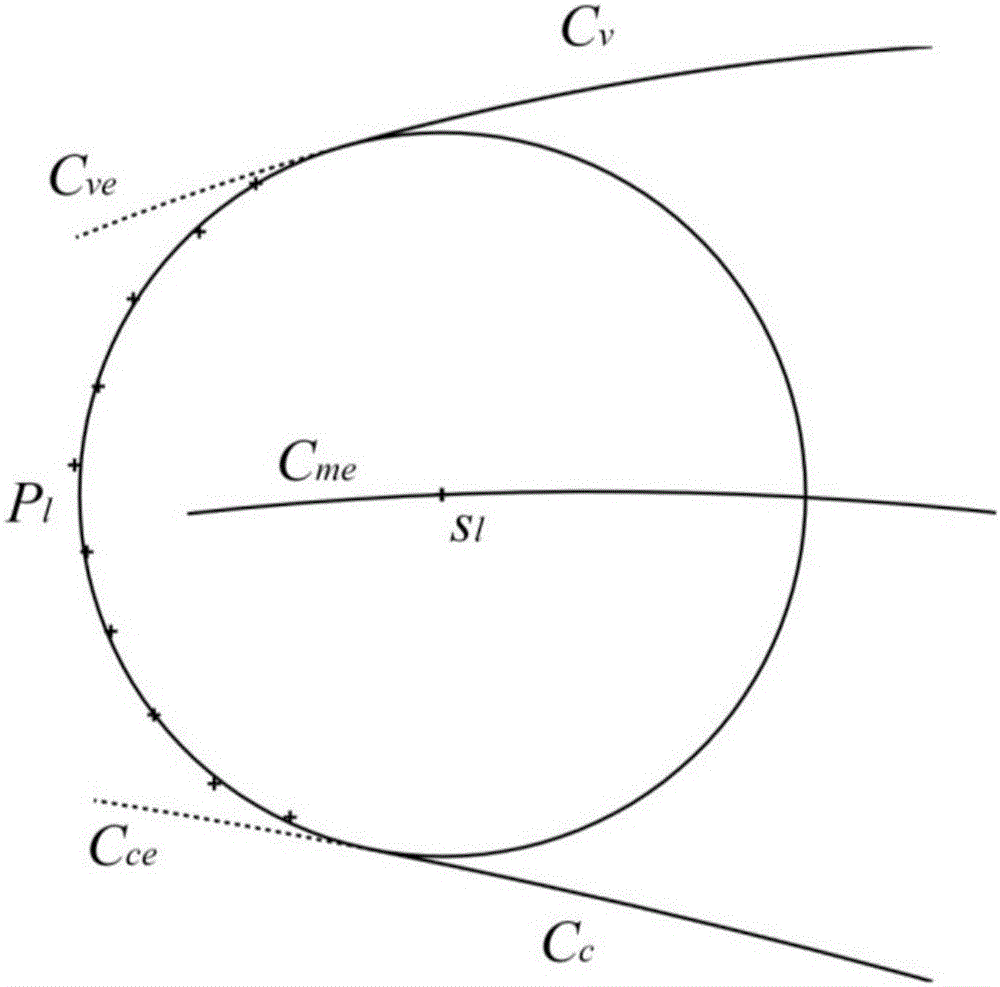

[0023] refer to figure 1 . The specific steps of the method for fitting the front and rear edges of the blade based on the center arc and the smooth reconstruction of the section line in the present invention are as follows:

[0024] Step 1. Select a certain section line measurement point of the blade as the research target, where the leading edge point set P l is the fitting object. Select the original leaf back curve C v and leaf pot curve C c is the auxiliary curve.

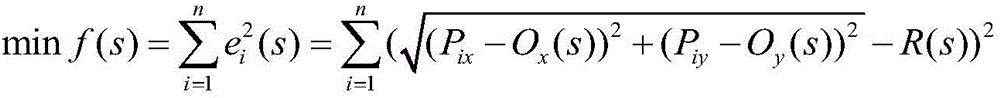

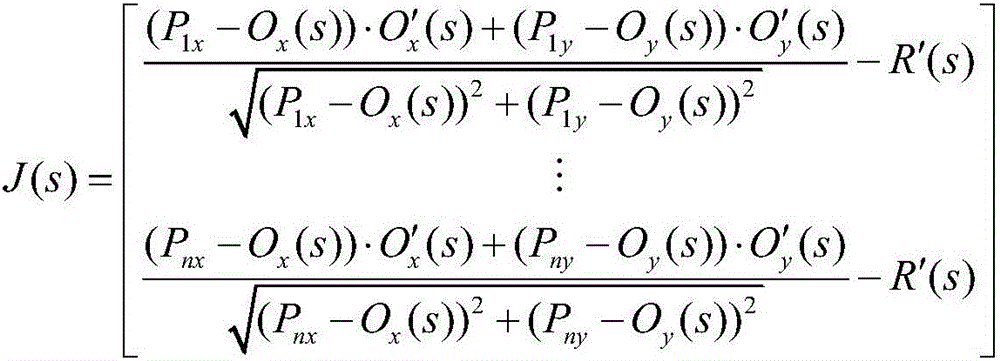

[0025] Step 2. On the leaf back curve C v and leaf pot curve C c On the basis of , use the middle arc and Gauss-Newton method to calculate the leading edge point set P l Fitting is carried out to obtain the leading edge curve C that satisfies the smooth connection between the leaf pot, the leaf back and the leading edge l , the specific process is as follows:

[0026] ① For the initial leaf back curve C v and leaf pot curve C c Apply the middle arc extraction algorithm to get the initial middle arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com