A Universal Bolt Locking Fixture

A technology of bolts and fixtures, which is applied in the field of fixtures, can solve the problems that affect the proofing cycle of new products, the processing parts cannot be used universally, and the manufacture of fixtures is cumbersome, etc., and achieve the effects of shortening the time of proofing, saving the cost of fixtures, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

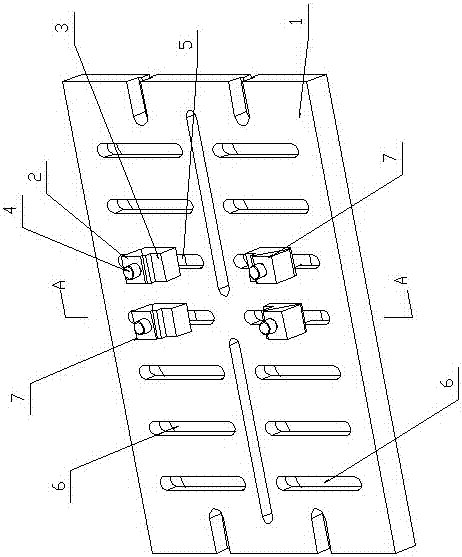

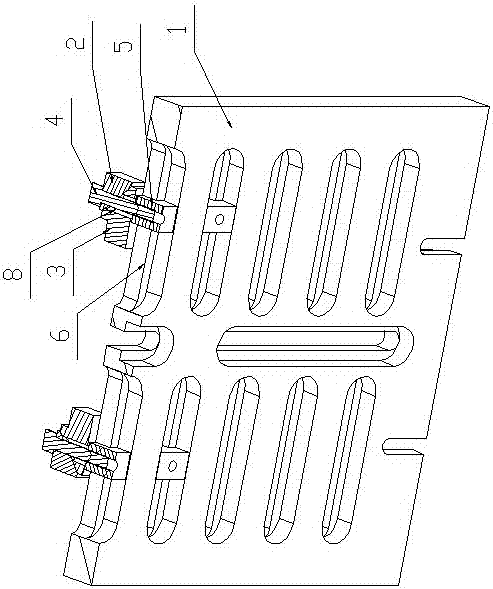

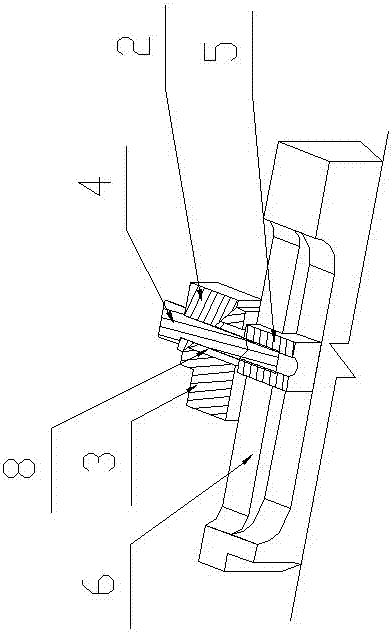

[0026] The structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1 to Figure 3 As shown, a general-purpose bolt-locking jig of the present invention includes a jig base plate 1, and at least two groups of long hole adjustment areas are arranged on the jig base plate 1 at intervals along the front and rear directions, and each set of elongated hole adjustment areas It includes a plurality of long holes 6 spaced left and right, and the long holes 6 of each group of long hole adjustment areas extend in the front and rear directions, and at least one bolt locking device 7 is provided in each of the two sets of long hole adjustment areas.

[0028] In this embodiment, two groups of long hole adjustment areas are arranged at intervals along the front and back directions on the bottom plate 1 of the forehead clamping fixture, and two bolt locking devices 7 are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com