Robotic system with reconfigurable end effector assembly

A technology of robot system and manipulator, applied in the field of robot system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

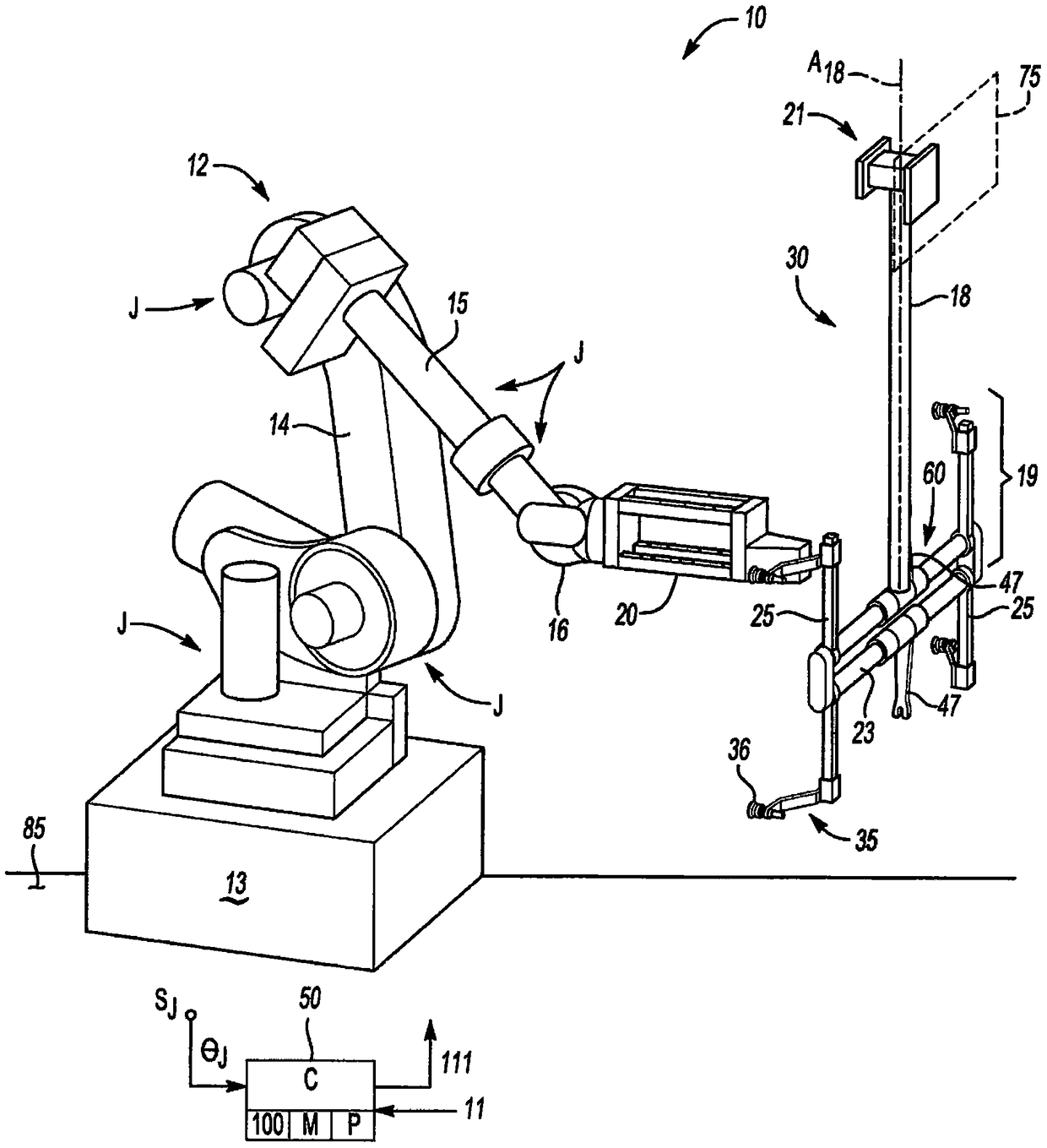

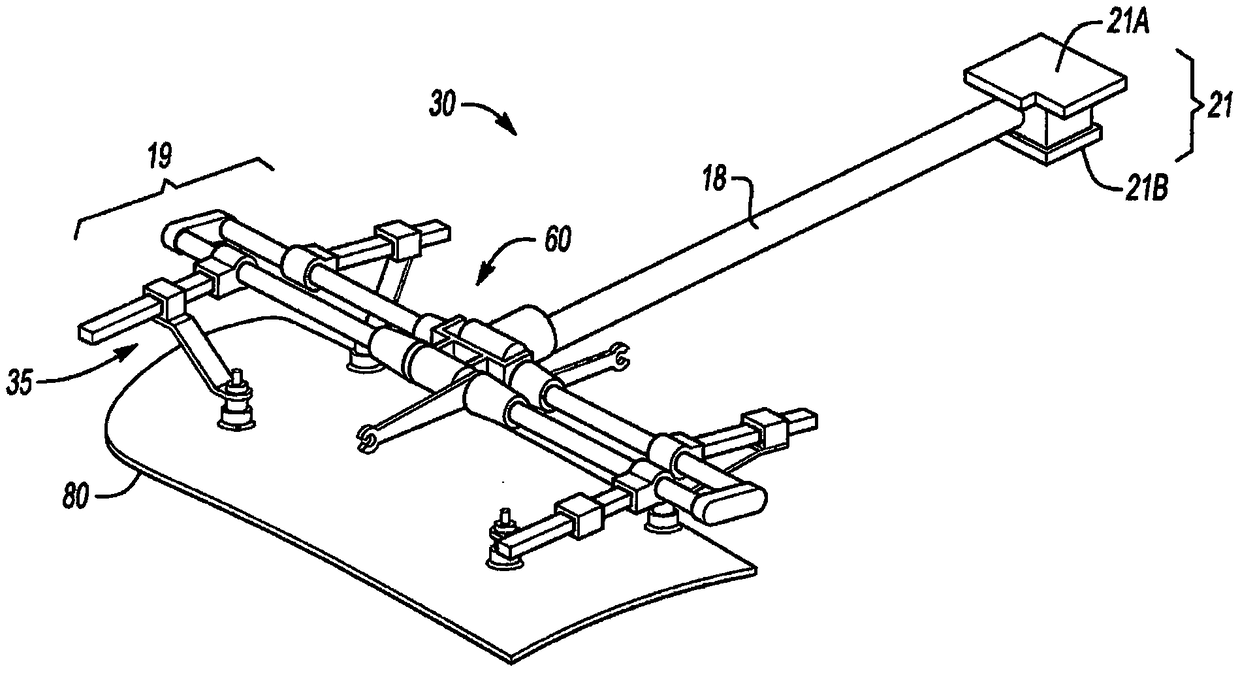

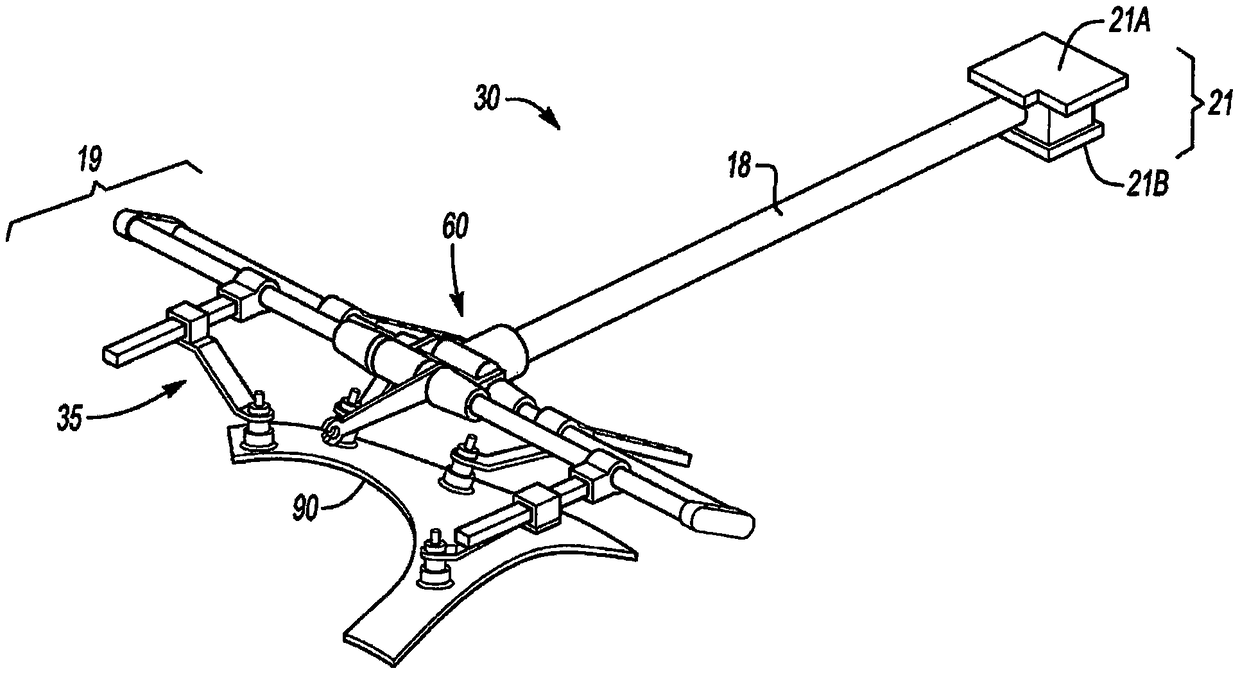

[0053] Referring to the drawings, wherein like reference numerals designate like parts throughout the several views, in figure 1 The robotic system 10 is schematically shown in . The robot system 10 includes a multi-axis industrial robot 12, Figure 5 and 6 The configuration tool 20 best shown in , and referenced below Figure 2A-4 and 7 describe the reconfigurable end effector assembly 30 in detail. Overall operational control of the robotic system 10 may be achieved by the controller (C) 50 via execution of the method 100, an example implementation of which is at Figure 8 shown in . Robotic system 10 may be included in Figure 9-11E The configuration rack 75, 175 described in detail in, the method 200 of using the configuration rack 75, 175 in Figure 12 shown in .

[0054] figure 1 The robot 12 may be implemented as a conventional 6-axis industrial robot as shown, and thus may include a fixed or moving base 13 and a plurality of robot joints J, at least some of whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com