Adjusting mechanism of driving mechanism of AGV trolley

A technology of drive mechanism and adjustment mechanism, which is applied to power units, vehicle components, electric power units, etc., can solve the problems of AGV not suitable for dense storage areas, insufficient flexibility and stability, and achieve the effect of solving the problem of vehicle steering speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

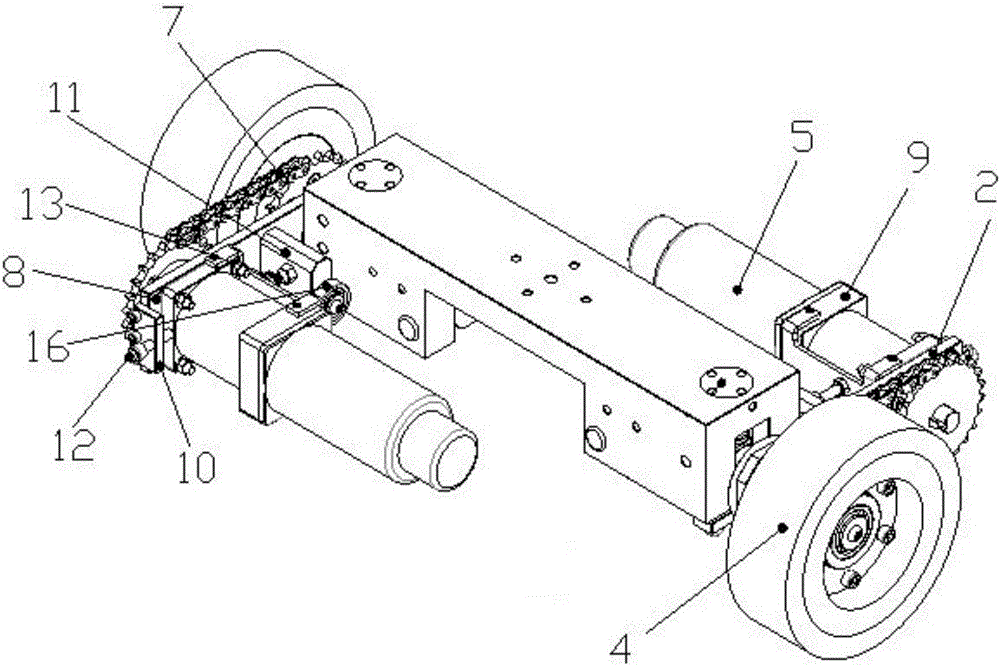

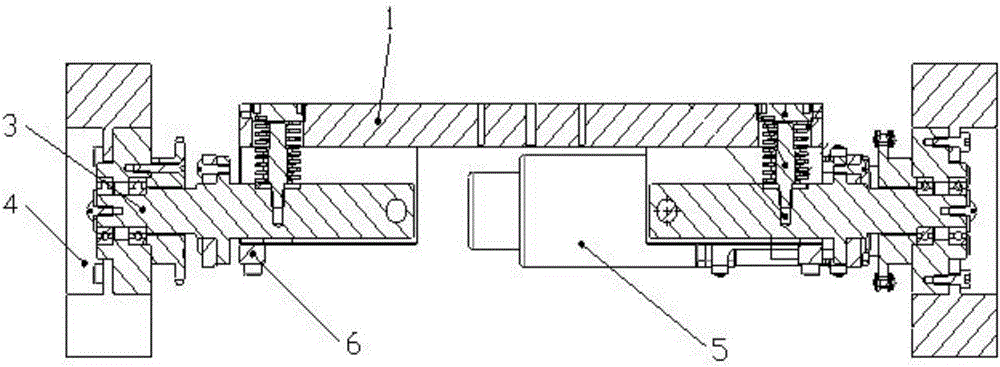

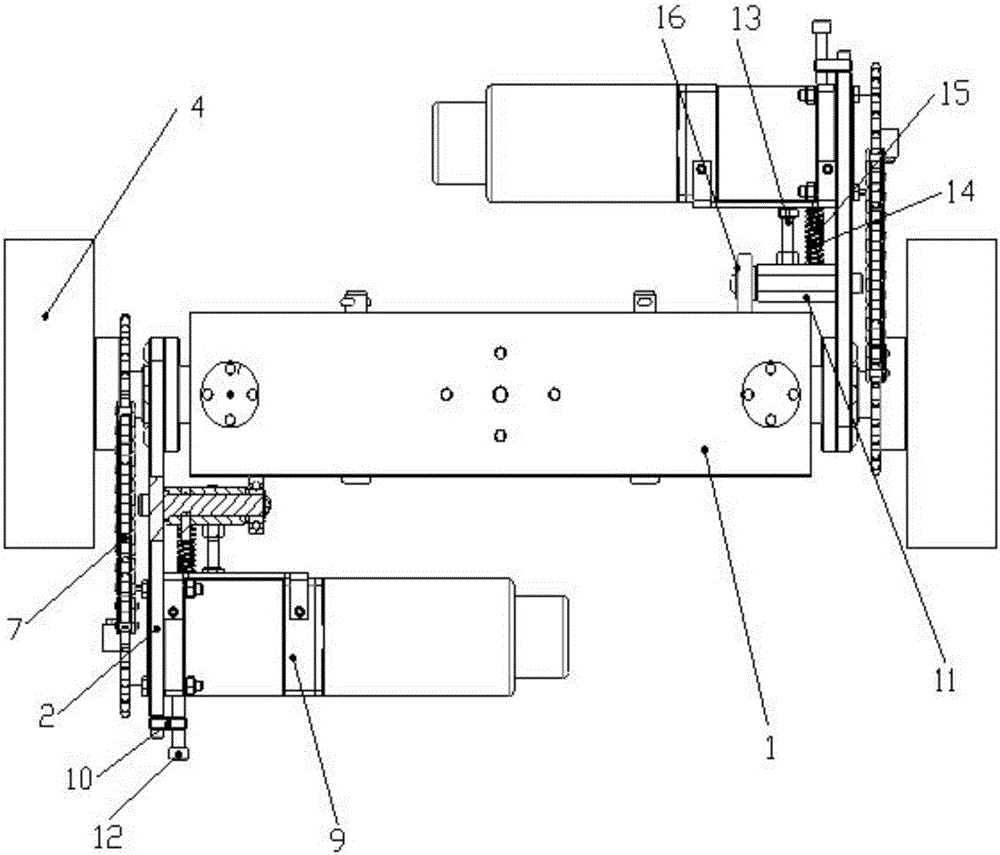

[0012] figure 1 Show the specific embodiment of the present invention: a kind of adjustment mechanism of AGV trolley drive mechanism, comprise drive mechanism base 1 and the fixed plate 2 that is arranged on drive mechanism base 1 two ends, be provided with drive mechanism on the fixed plate 2, described drive mechanism An adjusting mechanism is provided, and the driving mechanism includes a driving main shaft 3, a driving wheel 4 and a motor 5, the motor 5 is arranged on the fixed plate 2, the driving wheel 4 is arranged on the end of the driving main shaft 3, the two are connected in relative rotation, and the driving mechanism Both ends of the base 1 are provided with cavities, the drive spindle 3 is arranged in the cavity, the opening of the cavity is provided with a spindle baffle plate 6, and the drive wheel 4 and the motor 5 are connected by a chain assembly 7; the fixed plate 2 is provided with at least two parallel chutes 8, and the motor 5 is provided with a motor fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com