A handling robot based on elastic driving wheels

A handling robot and elastic drive technology, which is applied in the field of handling robots, can solve the problem of large energy consumption at the moment of starting the load of the motor safely handling the robot, and achieve the effect of avoiding stalled current and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

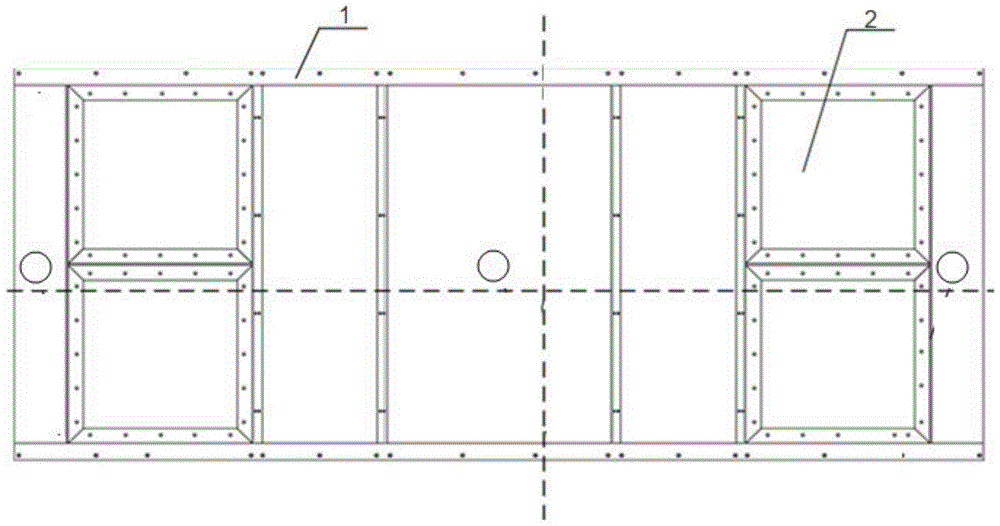

[0025] A handling robot based on elastic driving wheels, such as figure 1 As shown, it includes the AGV car body 1 and four elastic drive units installed under the AGV car body. The four elastic drive units are symmetrically distributed along the longitudinal axis and the transverse axis of the car body and installed on the drive units made at the front and rear ends of the AGV car body. Install in slot 2.

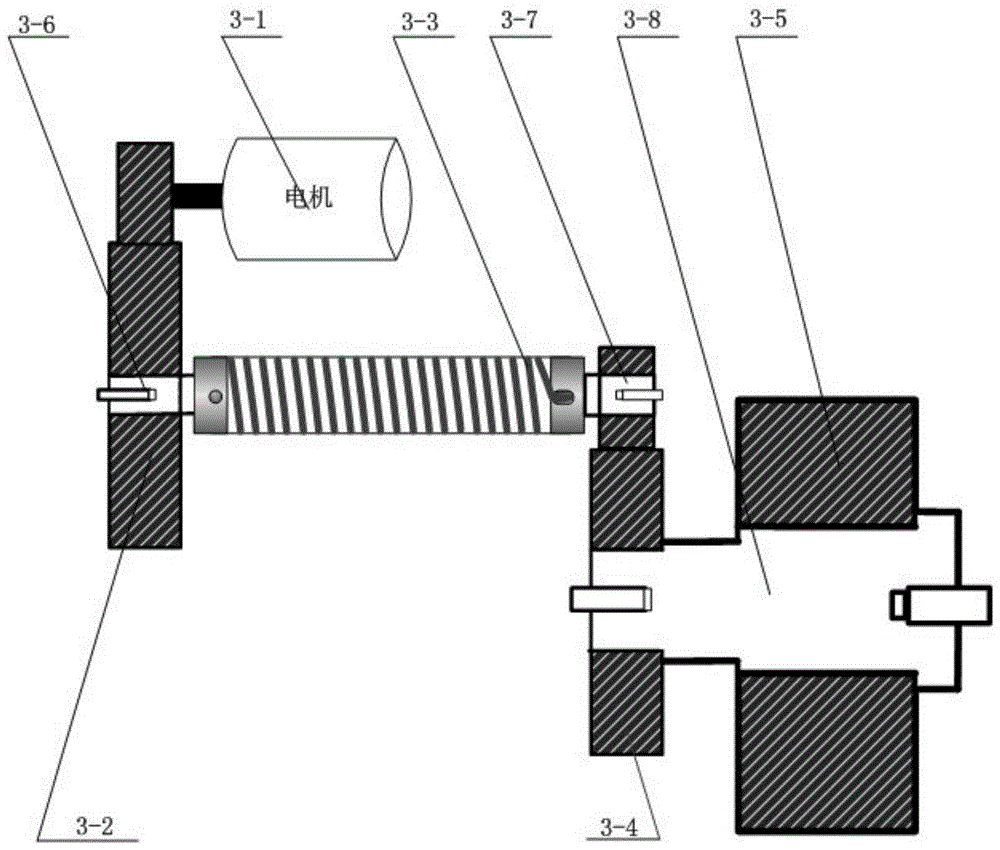

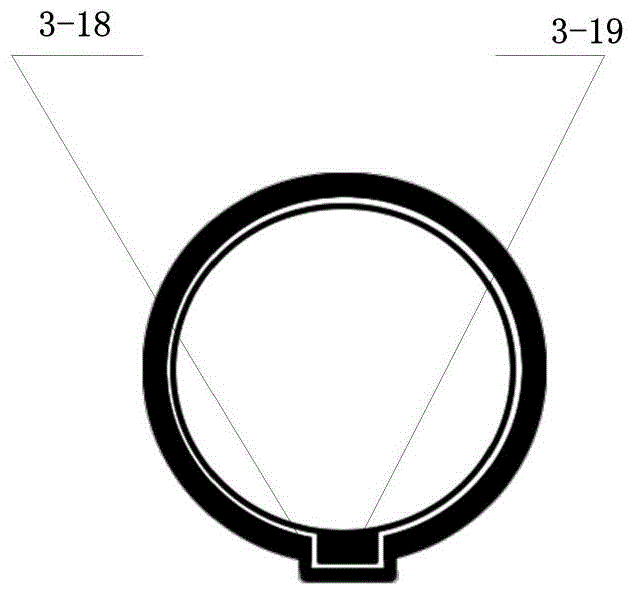

[0026] The elastic drive unit is a two-wheel drive unit using elastic drive wheels. Such as figure 2 As shown, the elastic drive wheel includes a motor 3-1, an input speed change mechanism 3-2, an output speed change mechanism 3-4 and a wheel 3-5, and the motor 3-1 and the input end speed change mechanism 3- 2 are connected together to form a power input end, and the output end speed change mechanism 3-4 is connected with the wheels 3-5 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com