hollow roller bearing

A roller bearing, hollow technology, applied in the field of bearings, can solve the problems of bearing damage, easy welding, loosening, etc., to achieve the effect of convenient installation, avoid easy welding, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

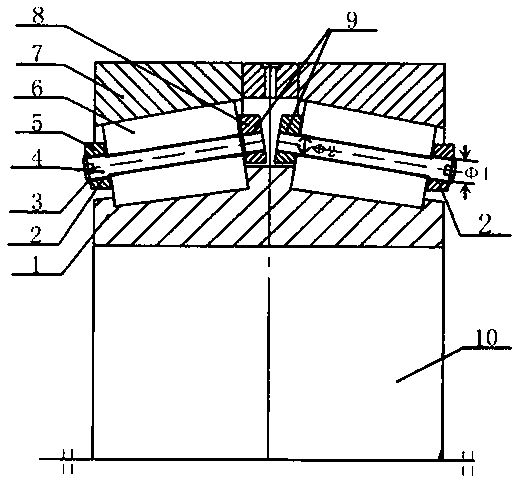

[0010] Embodiment one, with reference to the attached figure 1 , a hollow roller bearing, including a bearing inner ring 1 and a bearing outer ring 7, and a plurality of pairs of tapered rollers 6 are evenly distributed and symmetrically arranged between the bearing inner ring 1 and the bearing outer ring 7, and the tapered rollers 6 move freely Installed on the pillar 4, the thread one 2 at the outer end of the pillar 4 is threadedly connected with the small end cover 5 of the cage. 9 is threadedly connected with the large end cap 8 of the cage, the diameter Φ1 of the first thread is greater than the diameter Φ2 of the second thread, and its value is 1mm~20mm.

[0011] The center of the bearing inner ring 1 is provided with a shaft hole 10 for connecting with the shaft in the equipment.

[0012] When installing, insert the second thread diameter Φ2 of the pillar 4 from the first thread diameter Φ1, and weld the small end cover 5 of the cage with the pillar 4 through the weld...

Embodiment 2

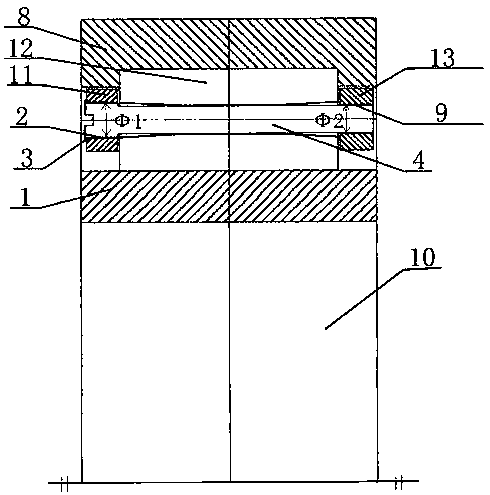

[0013] Embodiment two, referring to the attached figure 2 , the main technical features are exactly the same as those in Embodiment 1, except that the shapes of bearing inner ring 1 and bearing outer ring 7 are slightly different; only one cylindrical roller 12 is mounted on pillar 4, and cage end cover 2 11 is equivalent to the cage in Embodiment 1 The small end cap 5 and the cage end cap one 13 are equivalent to the cage big end cap 8 in the first embodiment; other structural features are the same.

[0014] When installing, insert the second thread diameter Φ2 of the pillar 4 from the first thread diameter Φ1, and after screwing the thread, weld the cage end cover 2 11 and the pillar 4 together through the welding spot 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com