Battery with current automatic cut-off device

An automatic cut-off and battery technology, applied in secondary batteries, exhaust plug devices, battery pack components, etc., can solve the problems of increased safety hazards, easy welding, and inability to resist battery vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The invention provides a battery equipped with an automatic current cut-off device, the battery at least includes a vent hole, the vent hole also includes a sealing rubber ring, and the battery also includes:

[0064] The battery body, the stress structure, the power-off structure and the lever structure; the stress structure, the power-off structure and the lever structure are located in a casing above the location of the exhaust hole of the battery body;

[0065] One end of the power-off structure is connected to the terminal board through an elastic component, and the elastic component has conductivity;

[0066] The middle part of the power-off structure includes a circular concave structure;

[0067] The stress structure is connected to the lever structure; the bottom surface of the stress structure is in contact with the exhaust hole; the part where the bottom surface of the power-off structure is in contact with the stress structure includes at least one elastic s...

Embodiment 2

[0087] The invention provides a battery equipped with an automatic current cut-off device, the battery comprising:

[0088] The battery includes at least one vent hole, the vent hole also includes a sealing rubber ring, and the battery also includes:

[0089] A battery body, a stress structure, a power-off structure, and a lever structure; the stress structure, the power-off structure, and the lever structure are located in a housing above the location of the exhaust hole of the battery body;

[0090] The stress structure is connected to the lever structure; the bottom surface of the stress structure is in contact with the vent hole; the outer diameter of the stress structure is smaller than the inner diameter of the circular hole where the vent hole is located;

[0091] One end of the power-off structure is connected to the terminal board through an elastic component, the elastic component has conductivity, the power-off structure includes a connecting substructure; the elast...

Embodiment 3

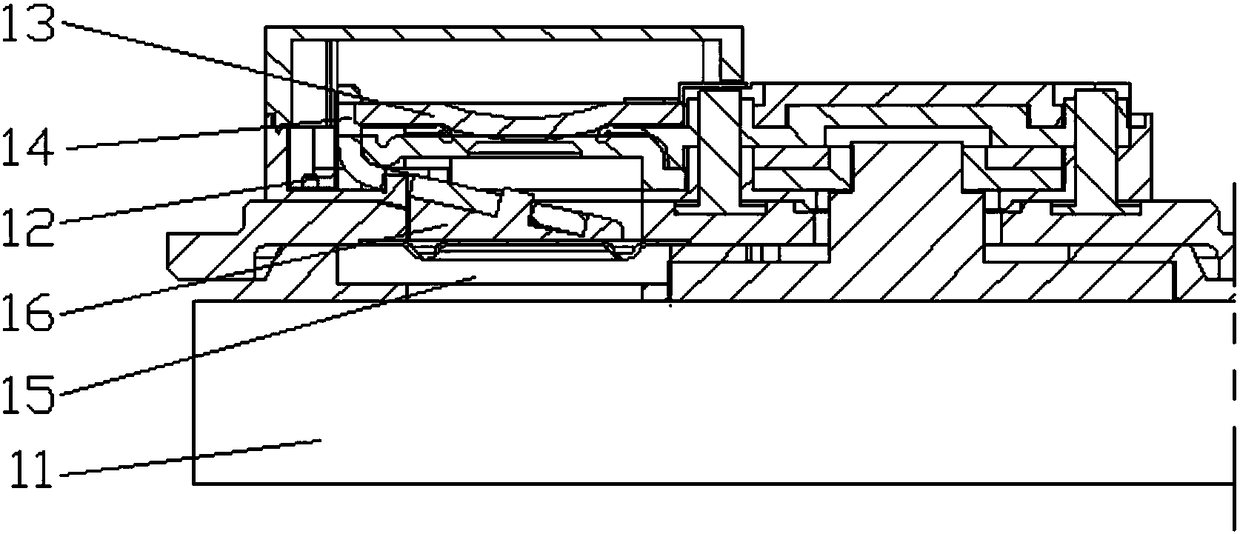

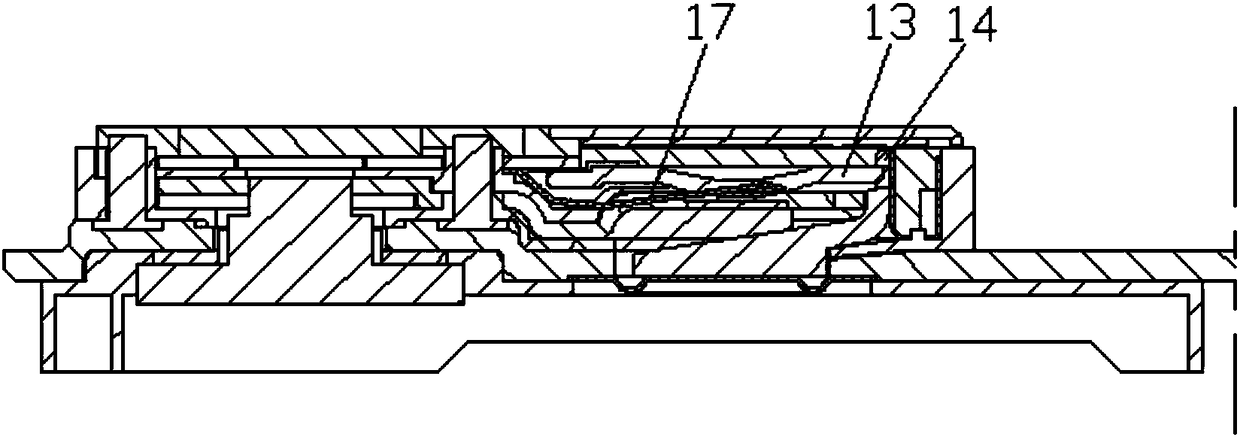

[0117] The invention provides a battery equipped with an automatic current cut-off device, referring to figure 1 As shown, the battery includes:

[0118] The battery includes at least one vent hole 15, and the vent hole 15 also includes a sealing rubber ring, and the battery also includes:

[0119]The battery body 11, the stress structure 12, the power-off structure 13, and the lever structure 14; the stress structure 12, the power-off structure 13, and the lever structure 14 are located in a casing above the location of the exhaust hole 15 of the battery body 11; the The connection method between the casing and the battery includes but is not limited to: in order to facilitate replacement or maintenance, the casing may also include a detachable connection part, which is detachably connected to the battery; at the same time, the detachable connection part may also include an adapter The adjustment device is convenient for matching batteries of various types and specifications...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com