A new type of vibration isolation pad for precision instruments

A technology of precision instruments and vibration isolation pads, applied in the field of new vibration isolation pads, can solve the problems of difficulty in isolation, affecting the service life of optical drives, low vibration isolation accuracy, etc. simple form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

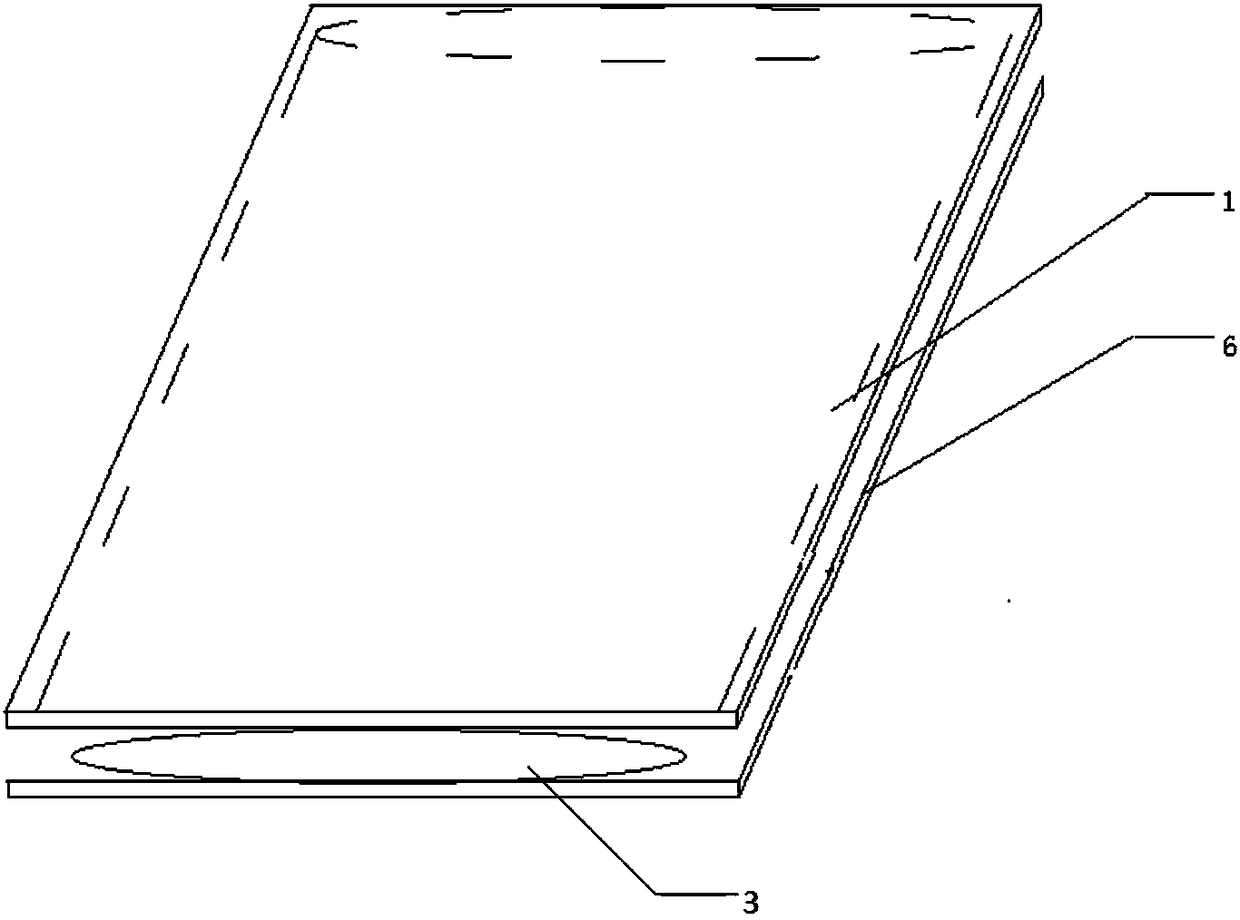

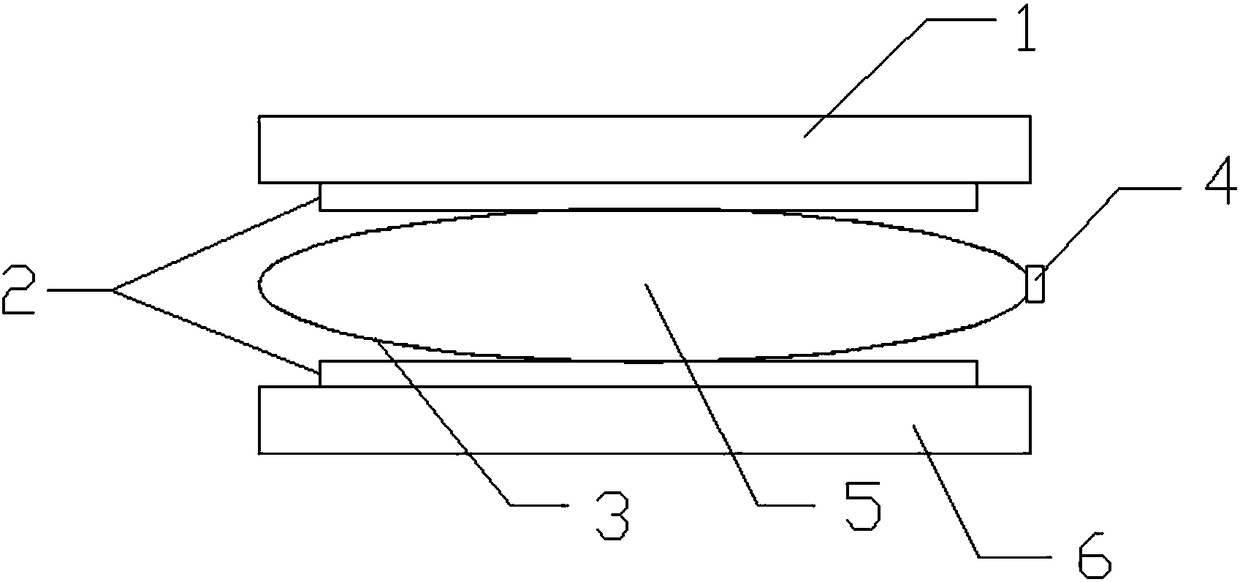

[0021] A precision instrument vibration isolation pad includes an upper support plate alloy 1, a nanomaterial coating 2, a soft vibration isolation energy-absorbing container 3, an air valve type liquid injection hole 4, viscous engine oil 5, and a lower support alloy plate 6.

[0022] The upper support alloy plate 1 and the lower support alloy plate are made of a nickel-titanium memory alloy, which has a slight shape memory function and can achieve a certain vibration isolation effect through its own deformation and energy absorption characteristics. The upper top surface and the lower bottom surface play the role of the first vibration isolation.

[0023] The nano-material coating 2 is arranged between the nickel-titanium alloy support plate 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com