Connector

A connector and connecting arm technology, which is applied in the direction of connection, fixed connection, and parts of the connection device, etc., can solve the problem of not imparting flexibility to the side joint piece 858.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

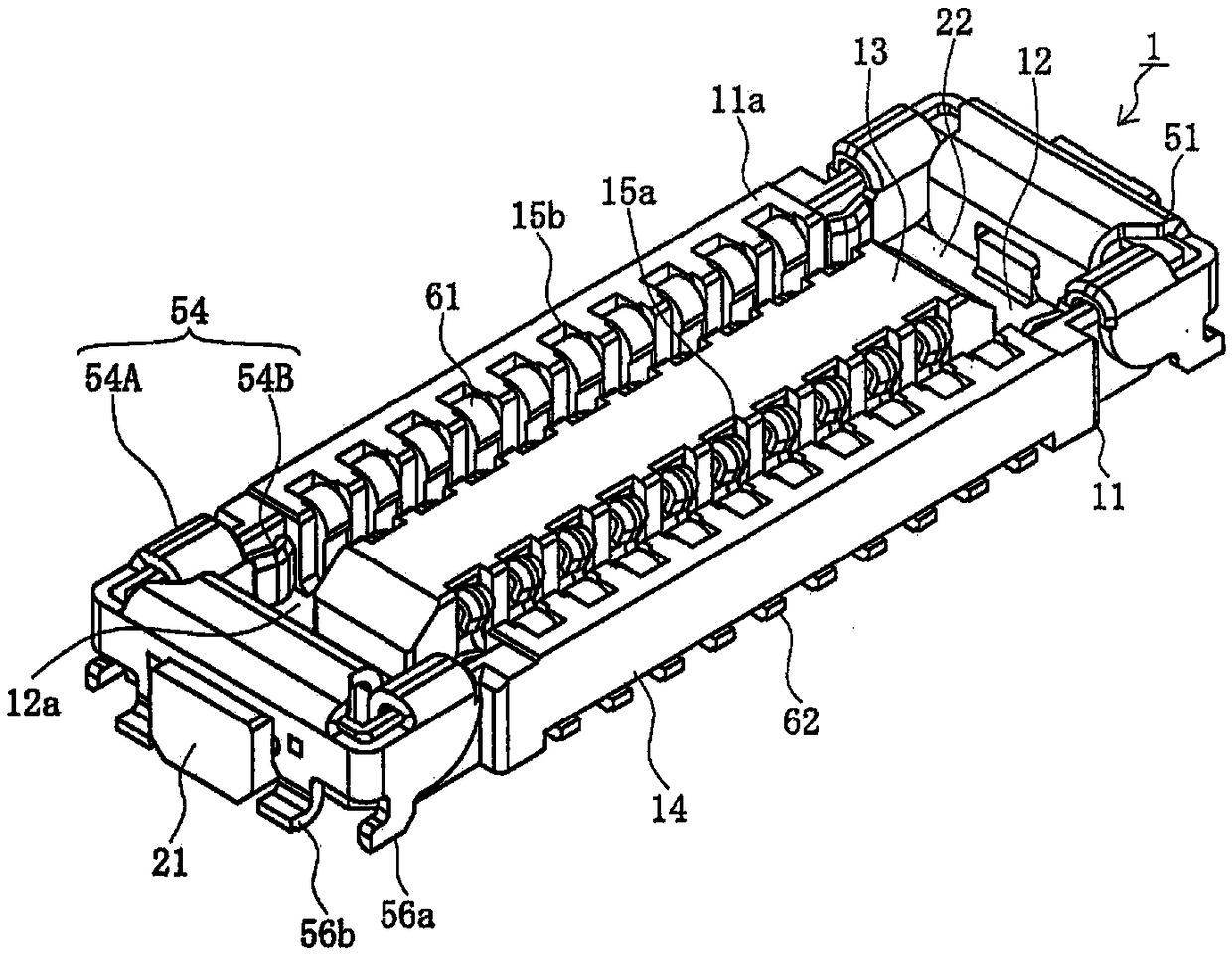

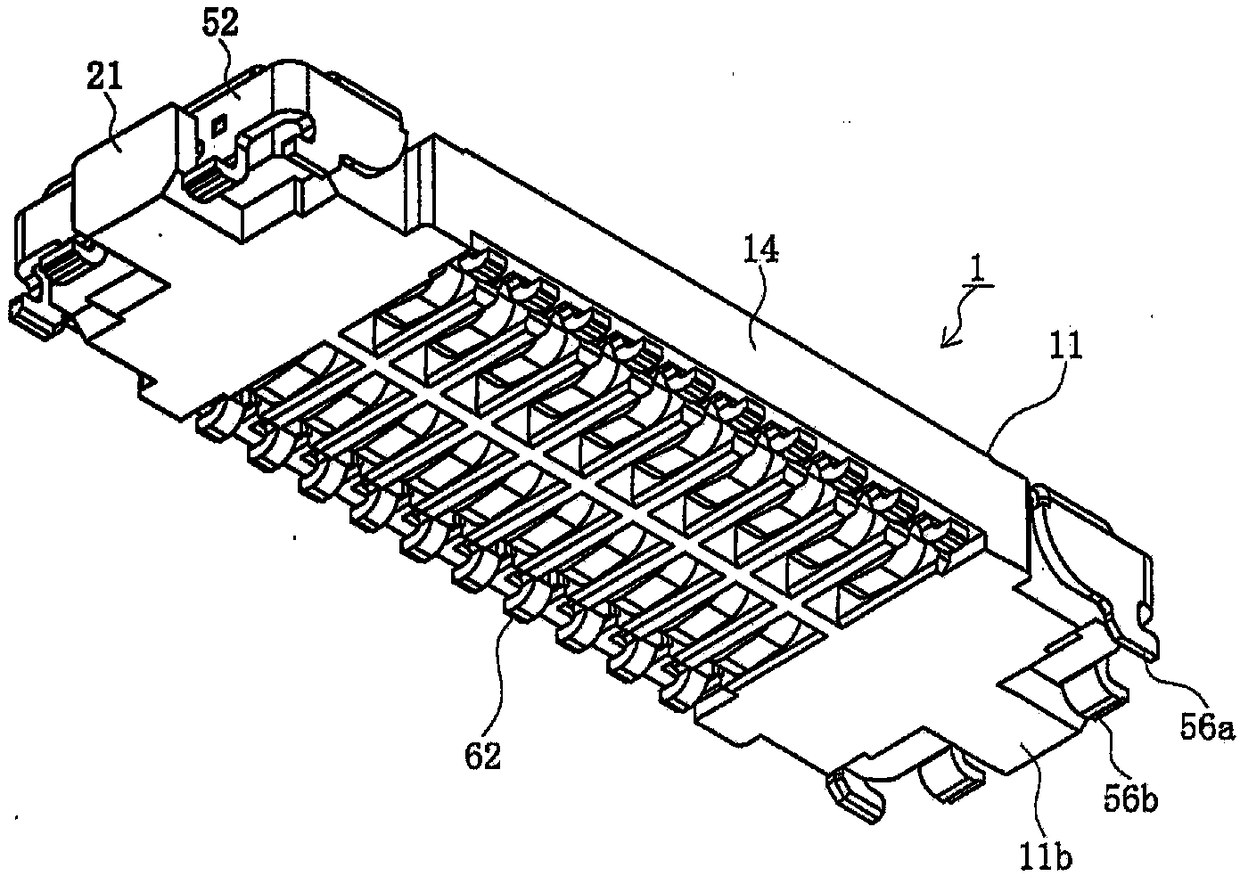

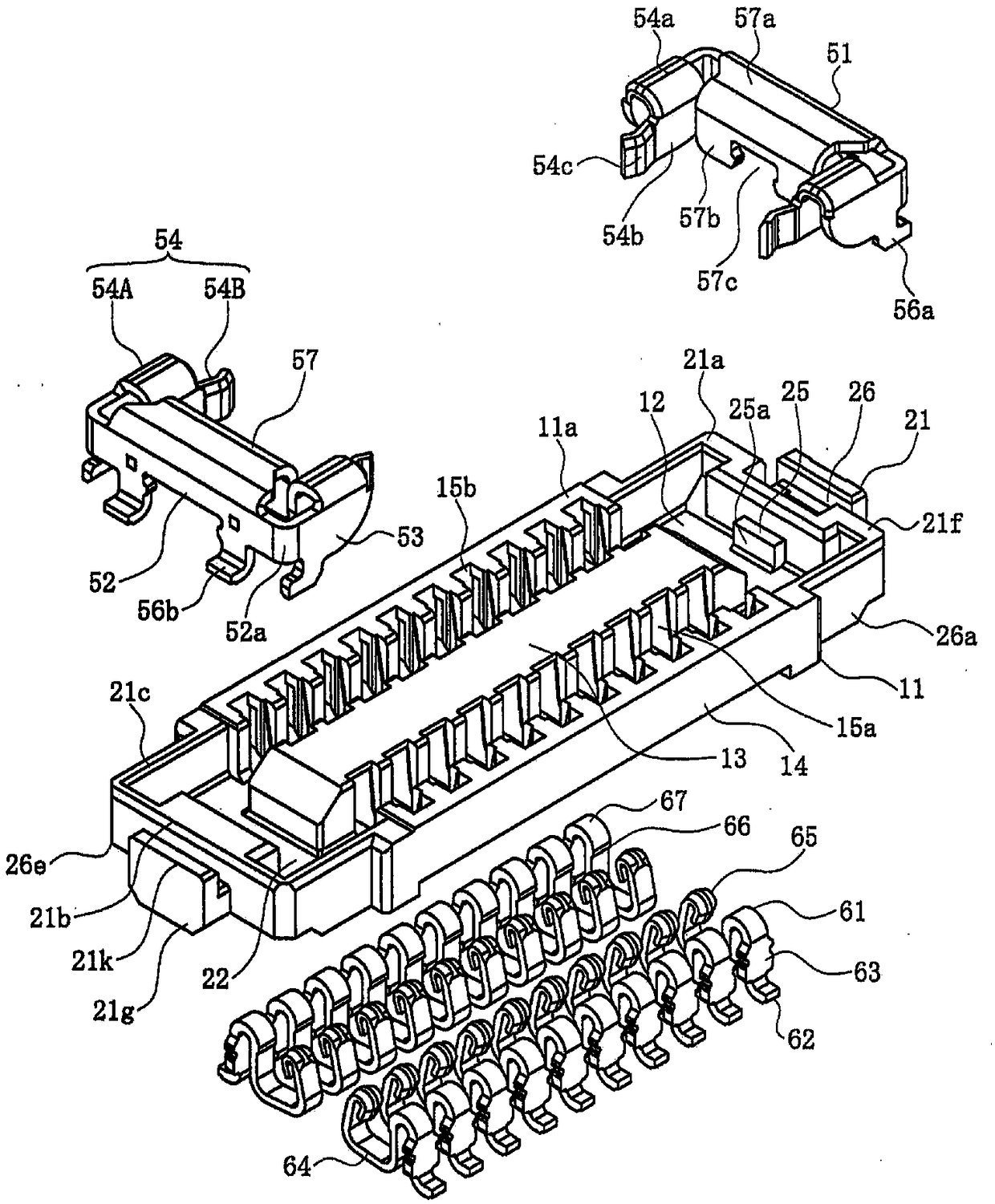

[0104] The following is a more detailed description of an embodiment of the invention with reference to the accompanying drawings.

[0105] FIG. 1 is a pair of perspective views of a first connector in an embodiment of the present invention. figure 2 is an exploded view viewed from above of the first connector in this embodiment of the present invention. image 3 is an exploded view viewed from below of the first connector in this embodiment of the present invention. Figure 4 is a side view of the first connector in this embodiment of the present invention. Figure 5 is six views of the first reinforcing metal fitting in this embodiment of the invention. In FIG. 1 , FIG. 1( a ) is a perspective view viewed from above, and FIG. 1( b ) is a perspective view viewed from below. In Fig. 5, Fig. 5 (a) is a front view, Fig. 5 (b) is a side view, Fig. 5 (c) is a rear view, Fig. 5 (d) is made along A-A among Fig. 5 (c) A cross-sectional view of Figure 5 (e) is a top view, and Figur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap