An agricultural roller ring and a land packer comprising a set of such agricultural roller rings

A roller ring, an agricultural technology, applied in the field of compacting rollers, can solve problems such as short service life, cracking of spoke connection points, increased structural weight and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

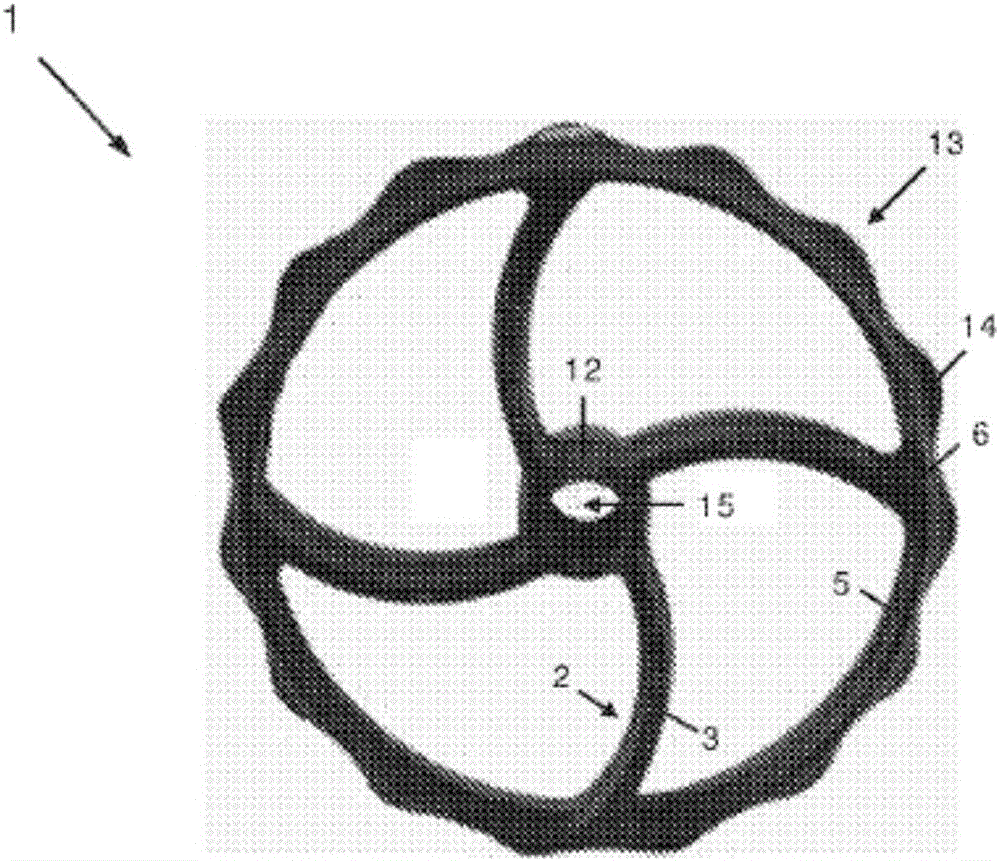

[0038] Figure 1 shows a prior art agricultural roll ring 1. The roller ring 1 includes: a hub portion 12 with a central hole 15 for receiving a shaft 9 (not shown in FIG. 1); a rim portion 13 with an outer surface 14 for compacting soil; and four spokes 2. Each spoke 2 has a body 3 connecting the hub portion 12 and the rim portion 13, and the connection point 6 of the body 3 and the rim portion 13 is located at the inner surface 5 of the rim portion 13.

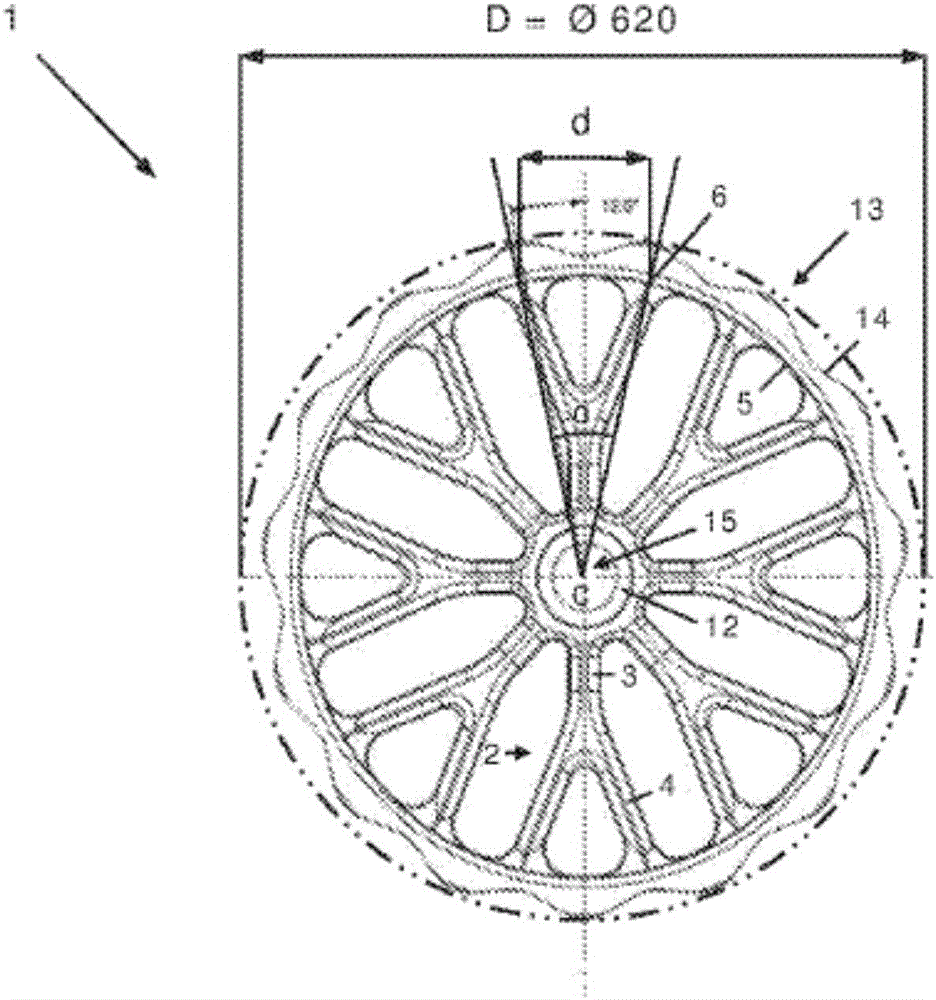

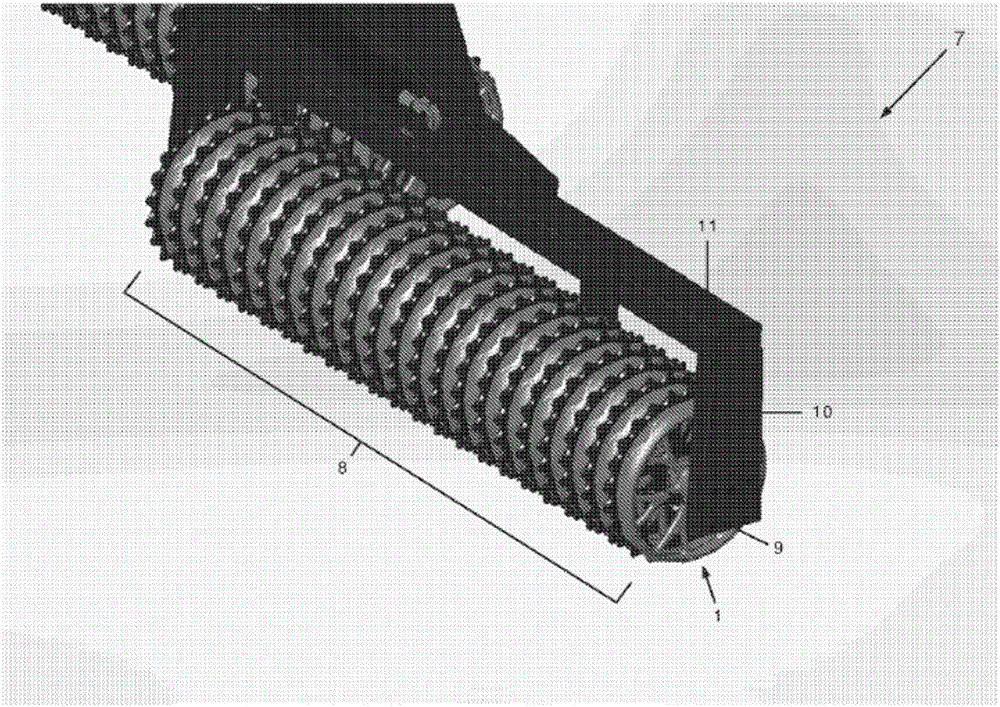

[0039] figure 2 The agricultural roll ring of the present invention is shown. The roller ring 1 includes a hub portion 12 having a central hole 15 for receiving a shaft 9 (refer to image 3 ), a rim portion 13 with an outer surface 14 for compacting soil, and eight spokes 2. Each spoke 2 is Y-shaped; in fact, each spoke 2 has a body 3 connecting the hub portion 12 and the rim portion 13. The body 3 is branched into multiple arms 4 in the direction toward the rim portion 13, so that the body 3 Connected to the inner surface 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com