A mobile phone frame parts processing jig

A mobile phone frame and component technology, which is applied to manufacturing tools, metal processing, workpiece clamping devices, etc., can solve the problems of low work efficiency, long operation time for jig replacement, and insufficient manual fixation and positioning accuracy, and achieve the clamping effect. Good, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

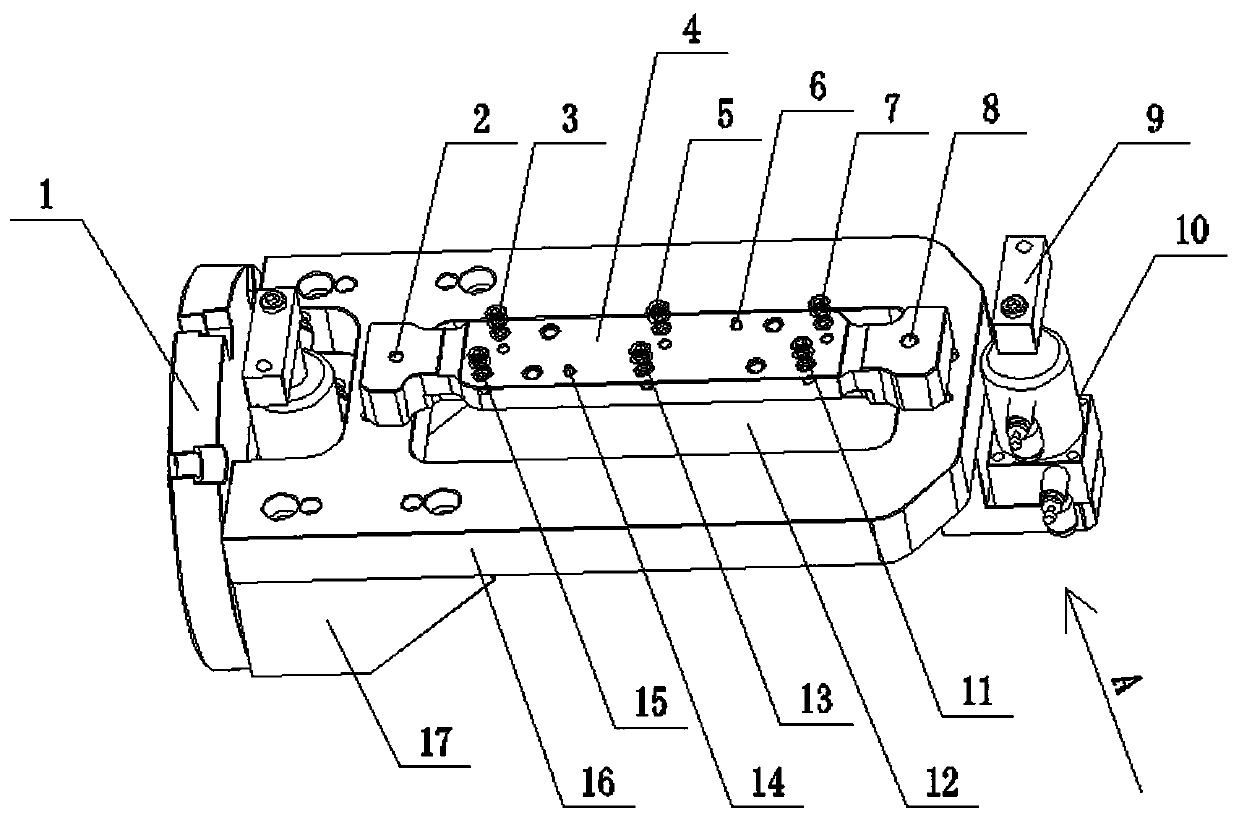

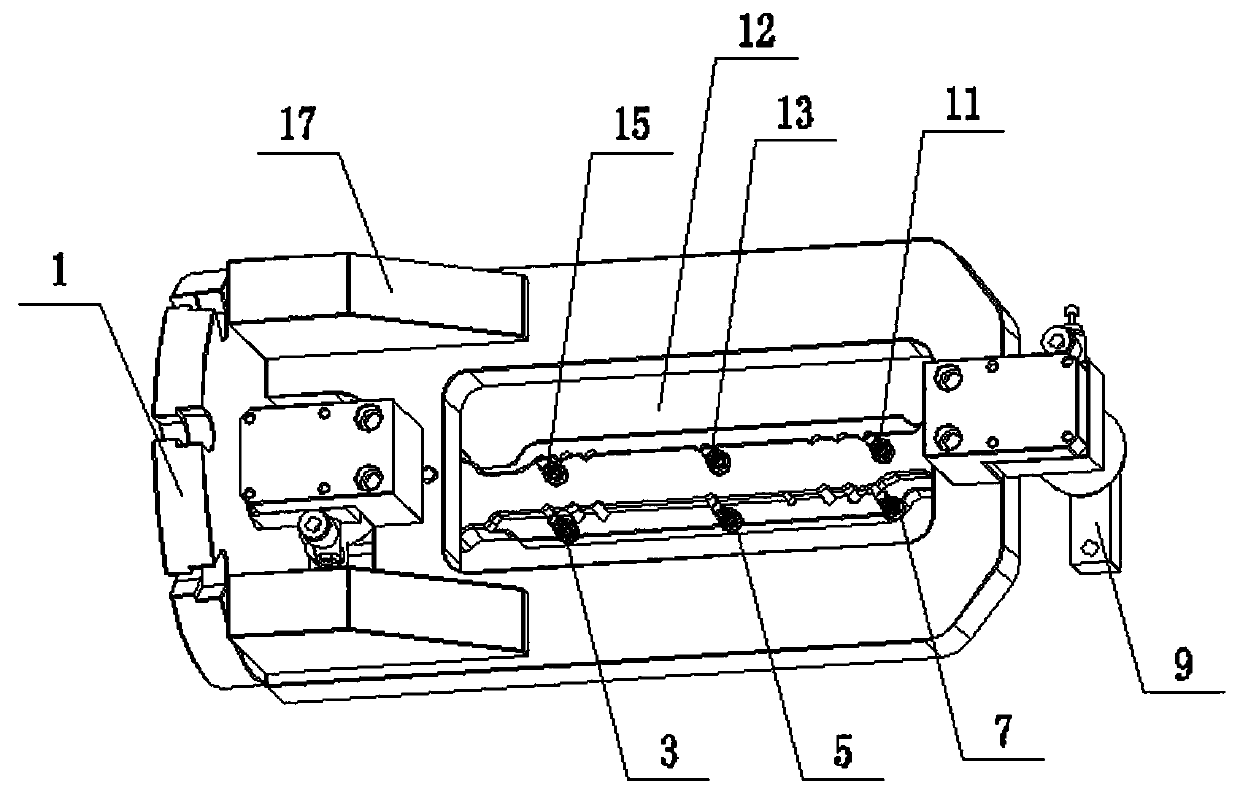

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 and figure 2 As shown, the present invention includes a vertically arranged flange 1, a support arm 17 is provided on the right side plane of the flange 1, and a positioning base plate 16 is fixedly connected to the top of the support arm 17 by bolts, and the positioning base plate The right end of 16 extends out of the support arm 17 to the right, and a rectangular hollow 12 is arranged in the middle of the positioning base plate 16. Component fixing plate 4, the left end of the component fixing plate 4 is fixed on the positioning base plate 16 by the first pin 2, and the right end of the component fixing plate 4 is fixed on the positioning base plate 16 by the second pin 8, the first pin 2 and The diameters of the second pin 8 are not equal, and the positioning bottom plate 16 is provided with threaded holes matched with the first pin 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com