Special clamping jaw for transmission cases

A gearbox and housing technology, applied in the field of special clamping jaws for gearbox housings, can solve the problems of low processing efficiency, backward fixing methods of gearboxes, inconvenient production, etc., and achieve the effect of protecting the cutter head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

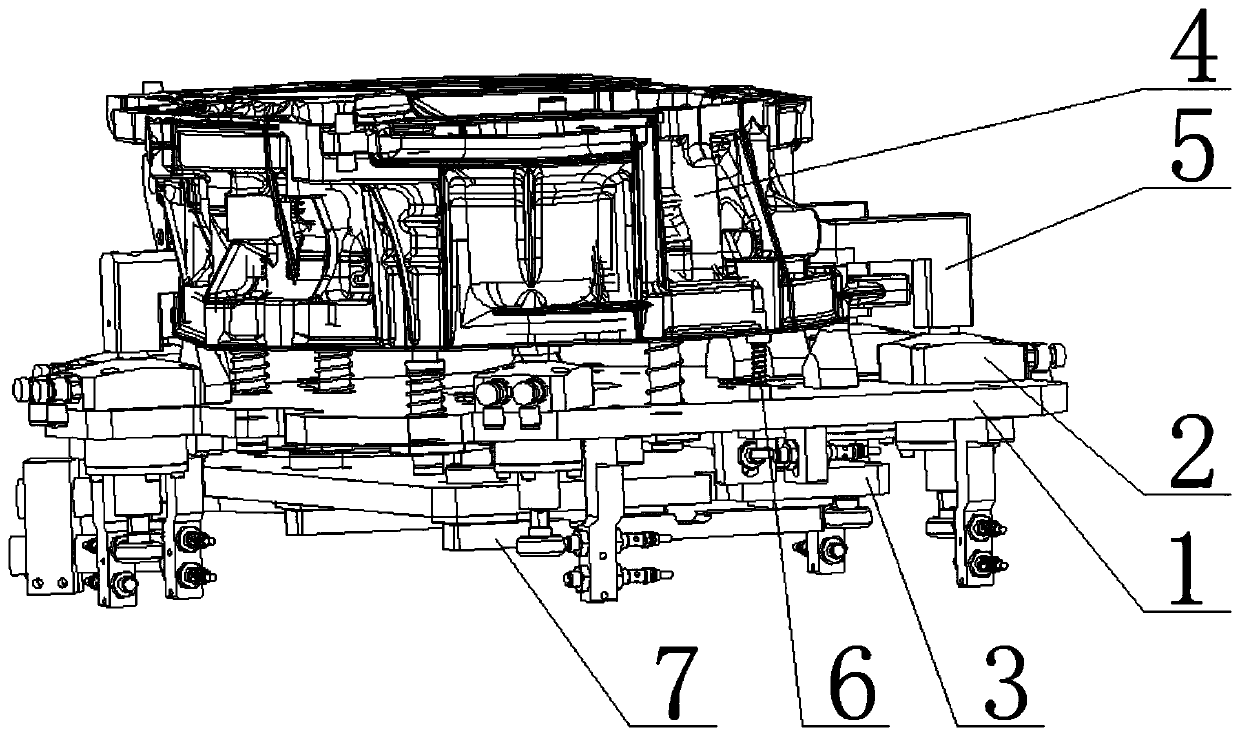

[0029] Such as Figure 1-2 As shown, a special clamping jaw for a gearbox housing includes a mounting plate 1 and a supporting plate 3 distributed in parallel, and at least one clamping member 2 for fixing a workpiece is fixedly installed on the outer edge of the mounting plate 1. The specific number and installation position of the clamping parts 2 are determined according to different styles of gearbox housings, preferably six, which are respectively detachably installed around the mounting plate 1 through a bolt fastening structure. In this embodiment, six clamps are preferred. The holder 2 is used to fix the workpiece of the gearbox casing, and one side of the gearbox casing is processed. plate, these six clamping parts can still fix the gearbox casing, improving the processing efficiency of the gearbox casing.

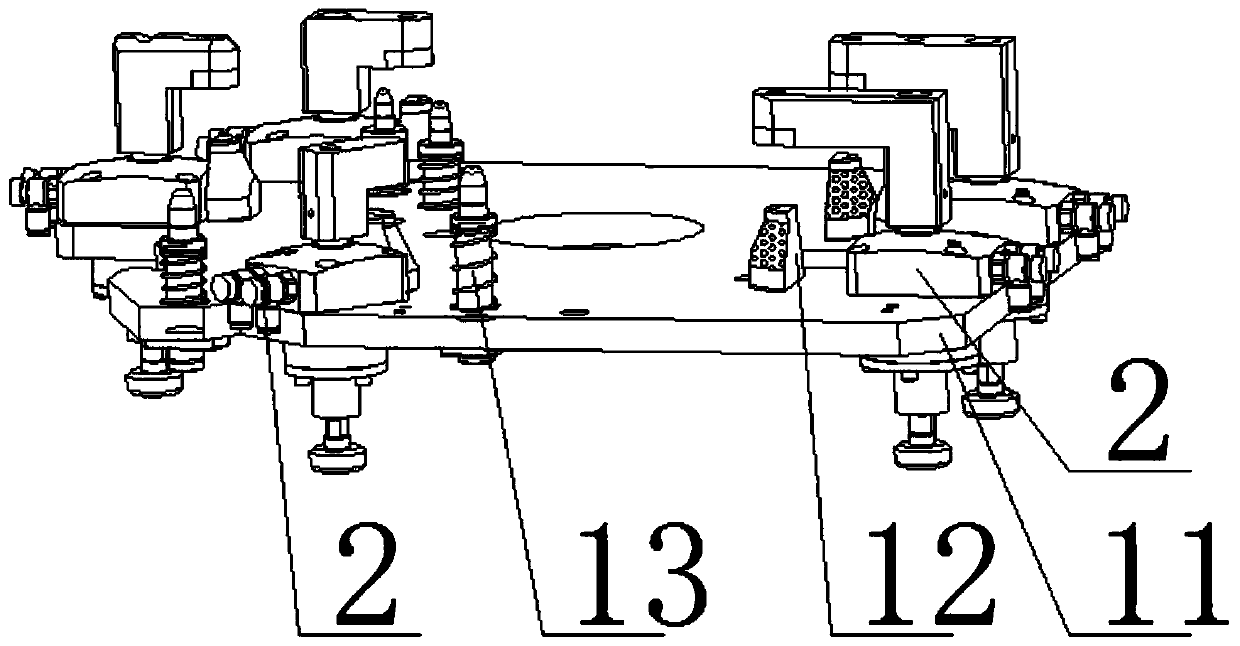

[0030] Such as figure 2 As shown, the mounting plate 1 includes a mounting plate body 11, an air blower 12, and an elastic positioning pin 13. The clamping mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com