A fully automatic subgrade and pavement ditch maintenance integrated machine execution device

A technology of an execution device and an integrated machine, which is applied to mechanically driven excavators/dredgers, earthmovers/shovels, construction, etc. The effect of high bucket sharpness, strong working ability and fast scraping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

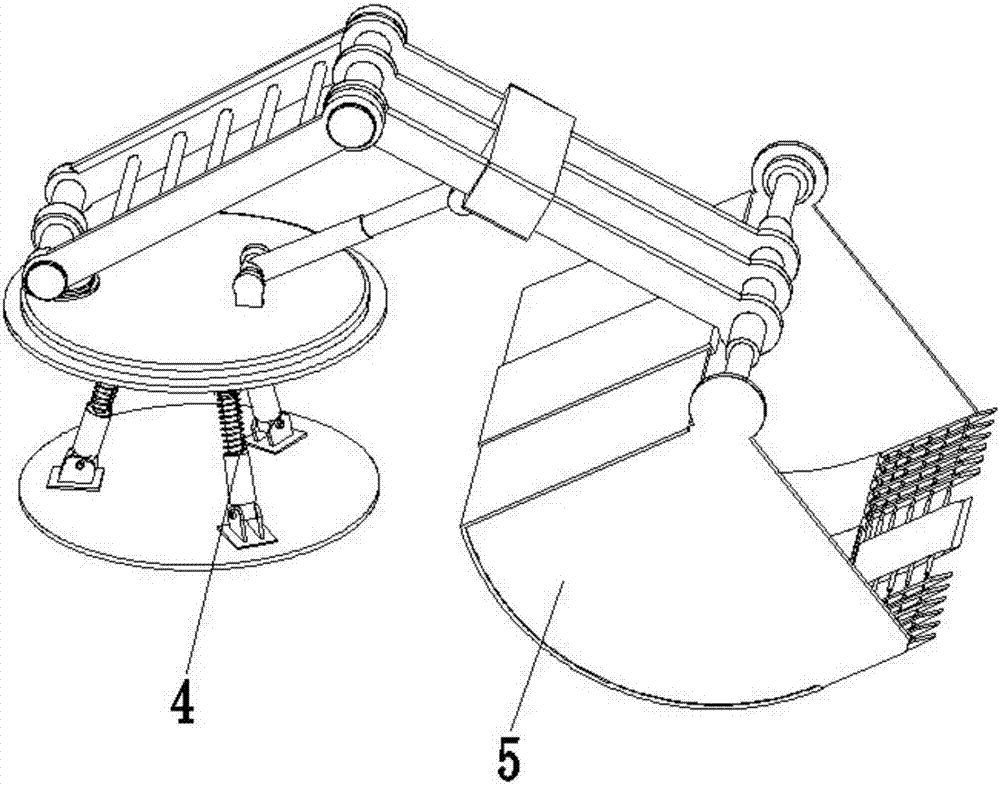

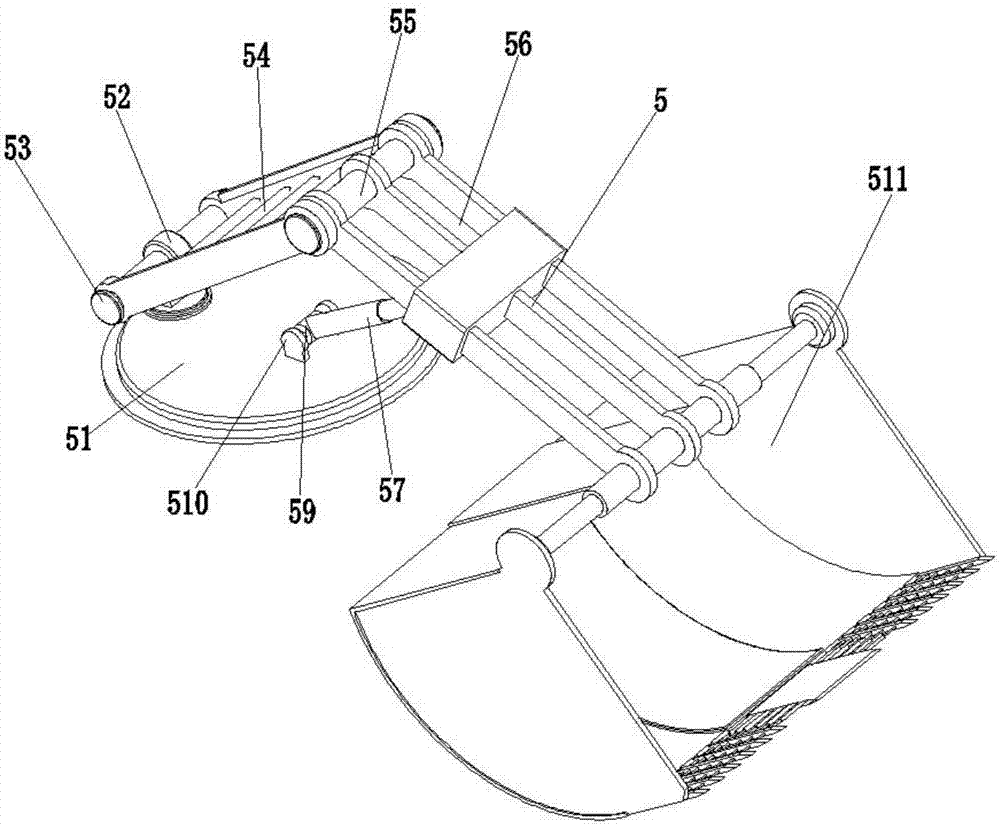

[0020] like Figure 1 to Figure 5 As shown, a full-automatic roadbed pavement ditch maintenance all-in-one implementing device includes a three-degree-of-freedom parallel mechanism 4 and a cleaning device 5; the three-degree-of-freedom parallel mechanism 4 is located directly below the cleaning device 5, and the three-degree-of-freedom parallel mechanism The upper end of the mechanism 4 is connected with the cleaning device 5 .

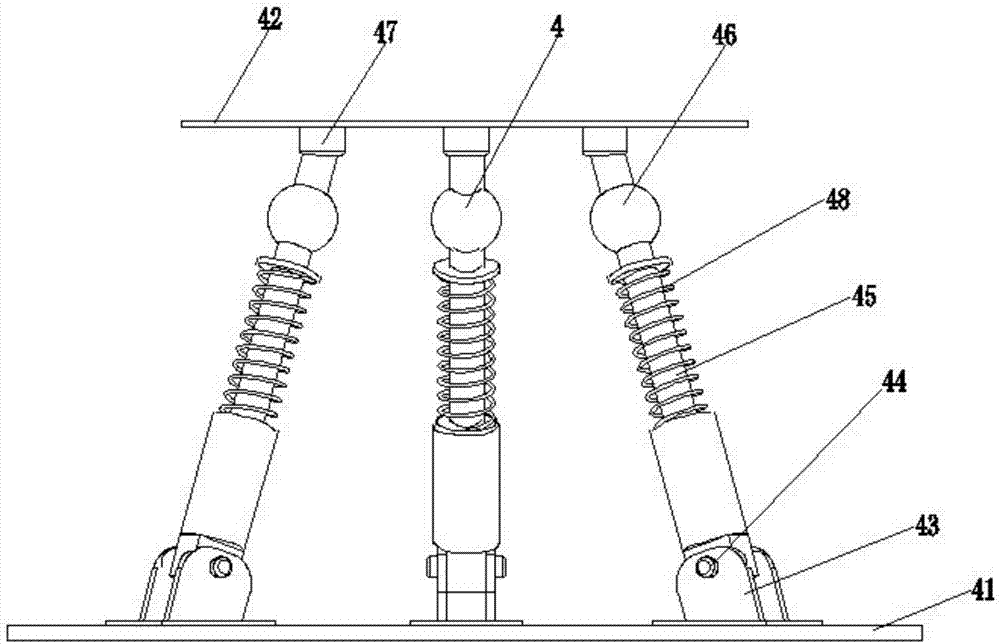

[0021] like figure 1 and figure 2 As shown, the three-degree-of-freedom parallel mechanism 4 includes a fixed platform 41, a moving platform 42, an ear seat 43, a rotating shaft 44, an electric push rod 45, a ball hinge 46, a connecting seat 47 and a limit spring 48, and the ear seat 43 , rotating shaft 44, electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com