Lock cylinder dust cover

A technology of dust cover and lock cylinder, applied in the field of locks, can solve the problems of inability to open, difficult to open, shortened life of locks, etc., and achieve the effect of easy unlocking operation and humanized design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] like Figure 1-7 Shown is a preferred embodiment of the present invention.

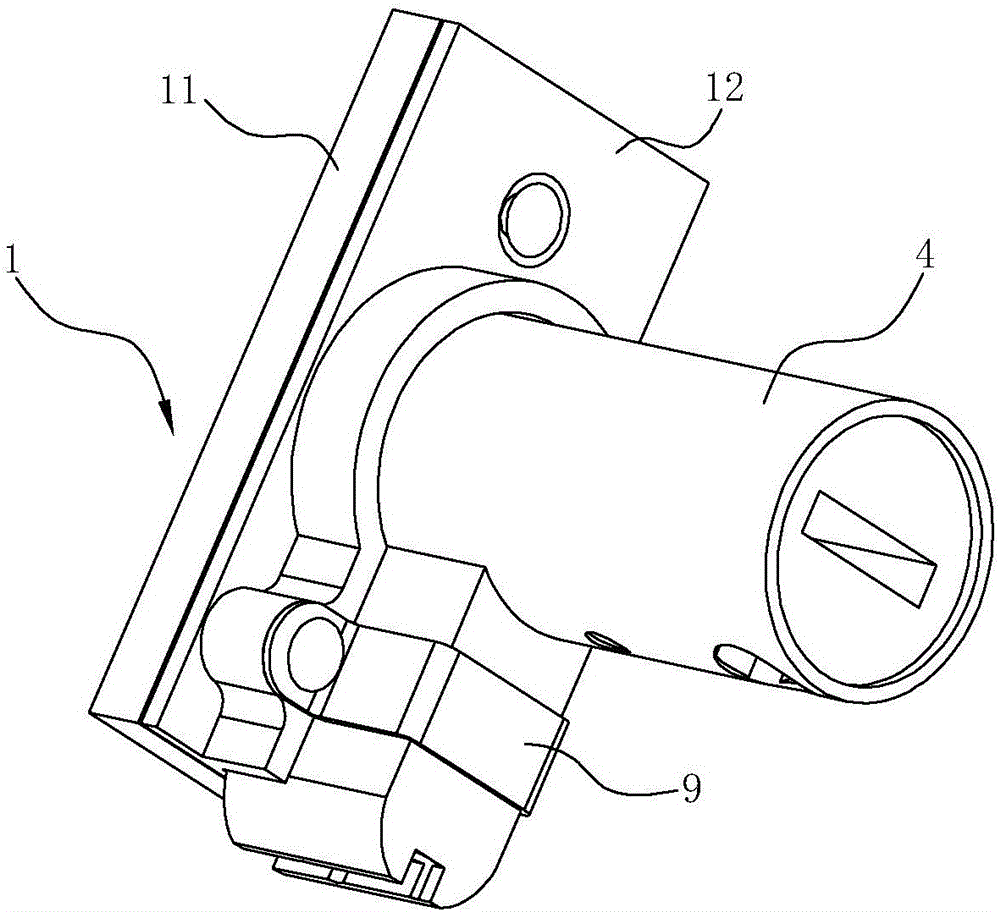

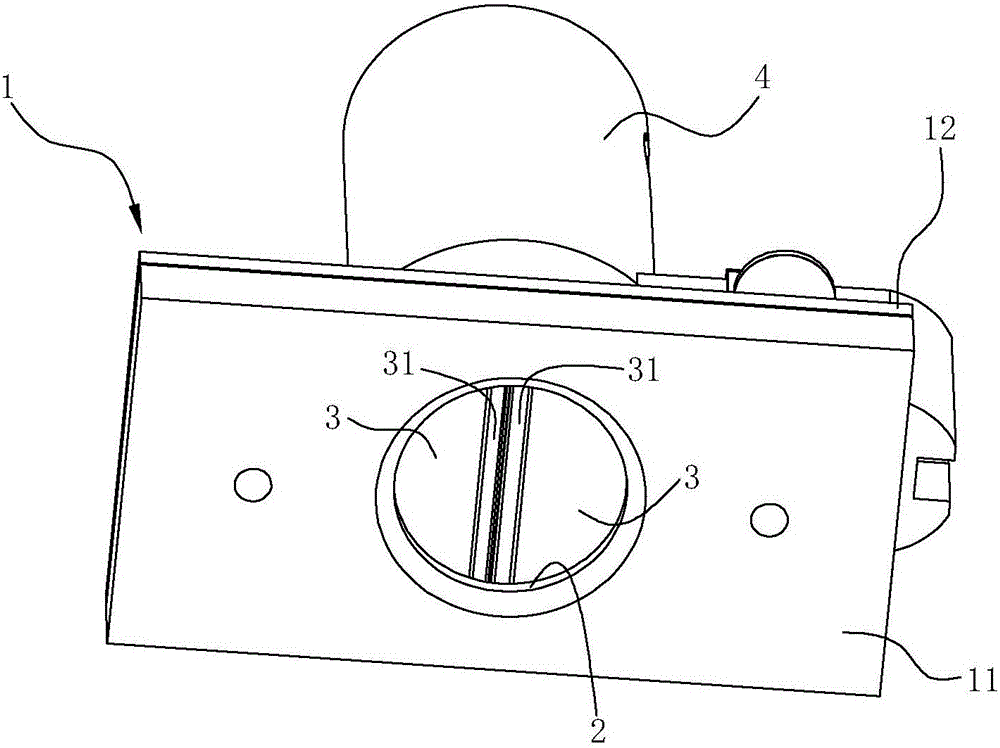

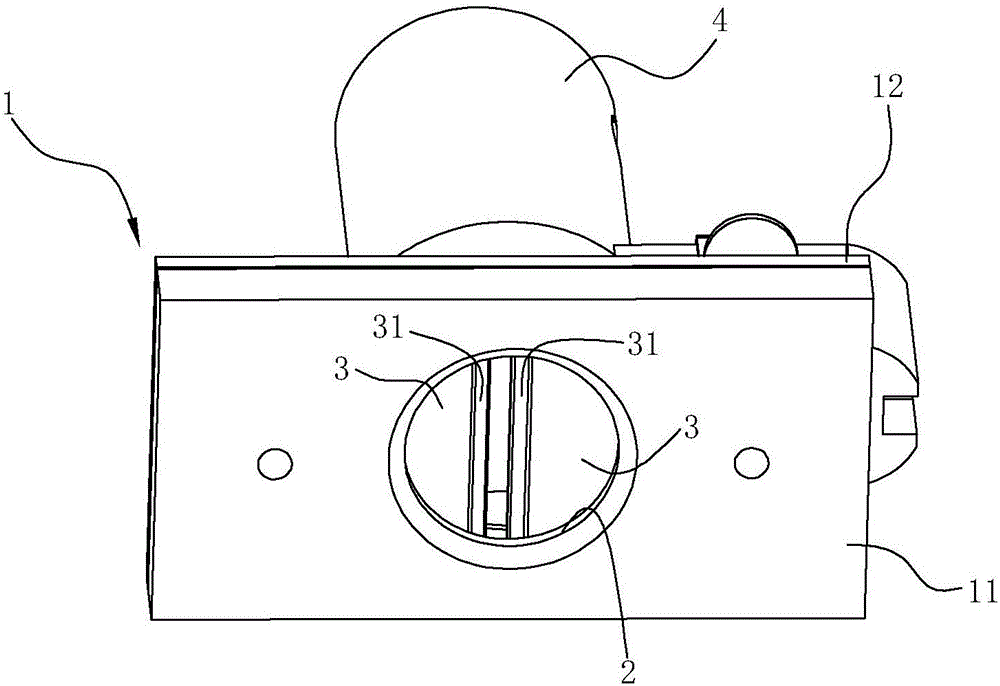

[0022] A lock cylinder dust cover, including a casing 1 for fixing on the lock cylinder 4 and having a housing cavity, which is roughly rectangular, and the casing 1 is formed by pairing a base 11 and a cover plate 12 and connecting them together by screws The back of the cover plate 12 has a concave cavity 13, and the front end of the lock core 4 is placed in the concave cavity 13 and fixed by the U-shaped pressing plate 9.

[0023] There are perforations 2 on the front and rear walls of the housing 1, that is, the bottom surface of the base 11 and the cover plate 12 are perforated 2, and the positions of the two perforations 2 correspond to each other. The blocking block 3 that can slide left and right, the blocking block 3 is constrained in the accommodati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com