Eccentric shaft

An eccentric shaft and eccentric wheel technology, applied in the field of eccentric shafts, can solve problems such as the inability to meet the needs of use, and achieve the effects of simplifying the difficulty of processing and assembly, solving the transmission resistance, and simplifying the design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

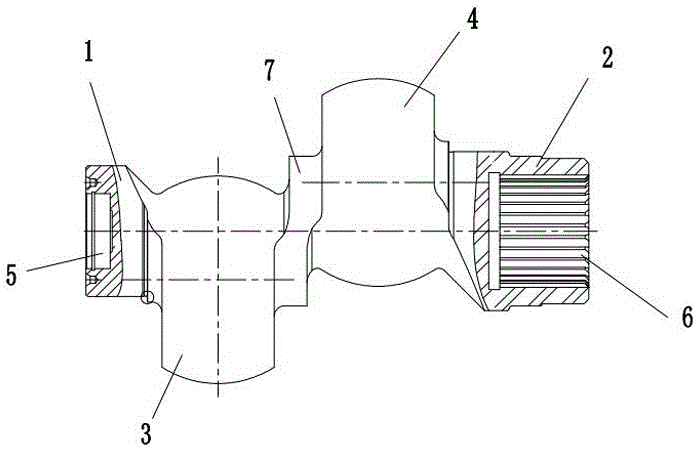

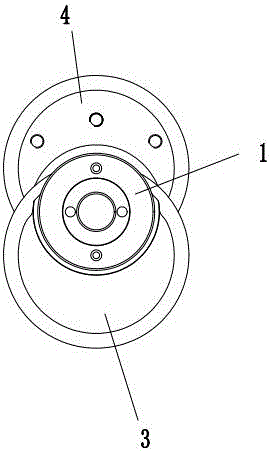

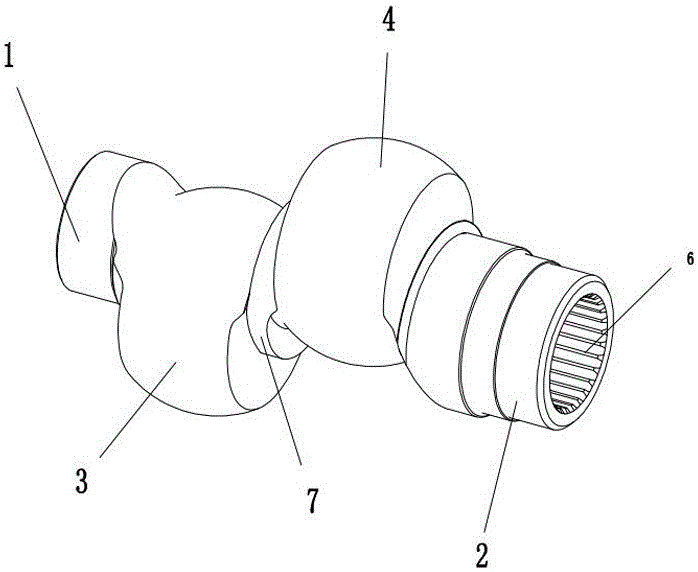

[0013] An eccentric shaft described in Embodiment 1, such as figure 1 , figure 2 and image 3 As shown, it includes a first shaft 1 and a second shaft 2, a first eccentric 3 and a second eccentric 4 that are arranged between the first shaft and the second shaft and are connected to each other, and the first eccentric and the second eccentric The first shaft is fixedly connected, the second eccentric wheel is fixedly connected with the second shaft; the first shaft is provided with a shaft groove 5, and the second shaft is provided with a gear groove 6; the first shaft and the second shaft The axes are all coaxial, the first axis of the first eccentric and the second axis of the second eccentric are not the same axis, the first axis and the second axis They are all at the same distance from the coaxial center line; the first axis line, the second axis line and the coaxial center line are all on the same plane.

[0014] A connecting wheel 7 is also arranged between the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com