Bottom sampling barrel

A sampling barrel and valve core technology, which is applied to sampling devices, lift valves, functional valve types, etc., can solve the problems of high randomness, inability to sample liquids, and unrepresentative sampling liquids, etc., to increase weight and increase sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

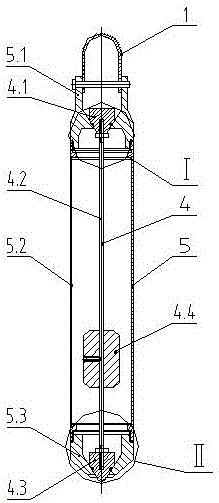

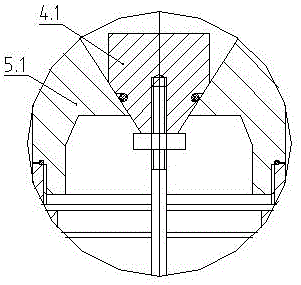

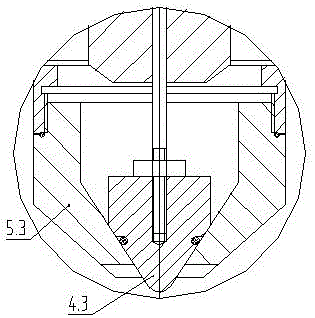

[0015] The bottom sampling bucket shown in the accompanying drawings includes a suspension ring 1, a housing assembly 5, and a valve core assembly 4; the housing assembly 5 is a hollow housing with a vertical central axis, including an upper end sleeve 5.1 fixedly connected up and down, and a housing 5.2 , the lower end sleeve 5.3; the suspension ring 1 is hingedly connected with the upper end sleeve 5.1; the valve core assembly 4 is arranged in the inner cavity of the housing assembly 5, including the upper valve core 4.1, the connecting rod 4.2, the lower valve core 4.3, the counterweight 4.4, and the connecting rod 4.2 The central axis is vertical, the upper valve core 4.1 and the lower valve core 4.3 are respectively fixedly connected to the upper and lower ends of the connecting rod 4.2, the counterweight 4.4 is set on the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com