Functional testing device, control server and method for distributed control system

A distributed control and control server technology, applied in the direction of electrical testing/monitoring, etc., can solve the problems of the test device being unable to complete the operation and check the status, high test cost, heavy work, etc., to achieve the effect of convenient function test and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

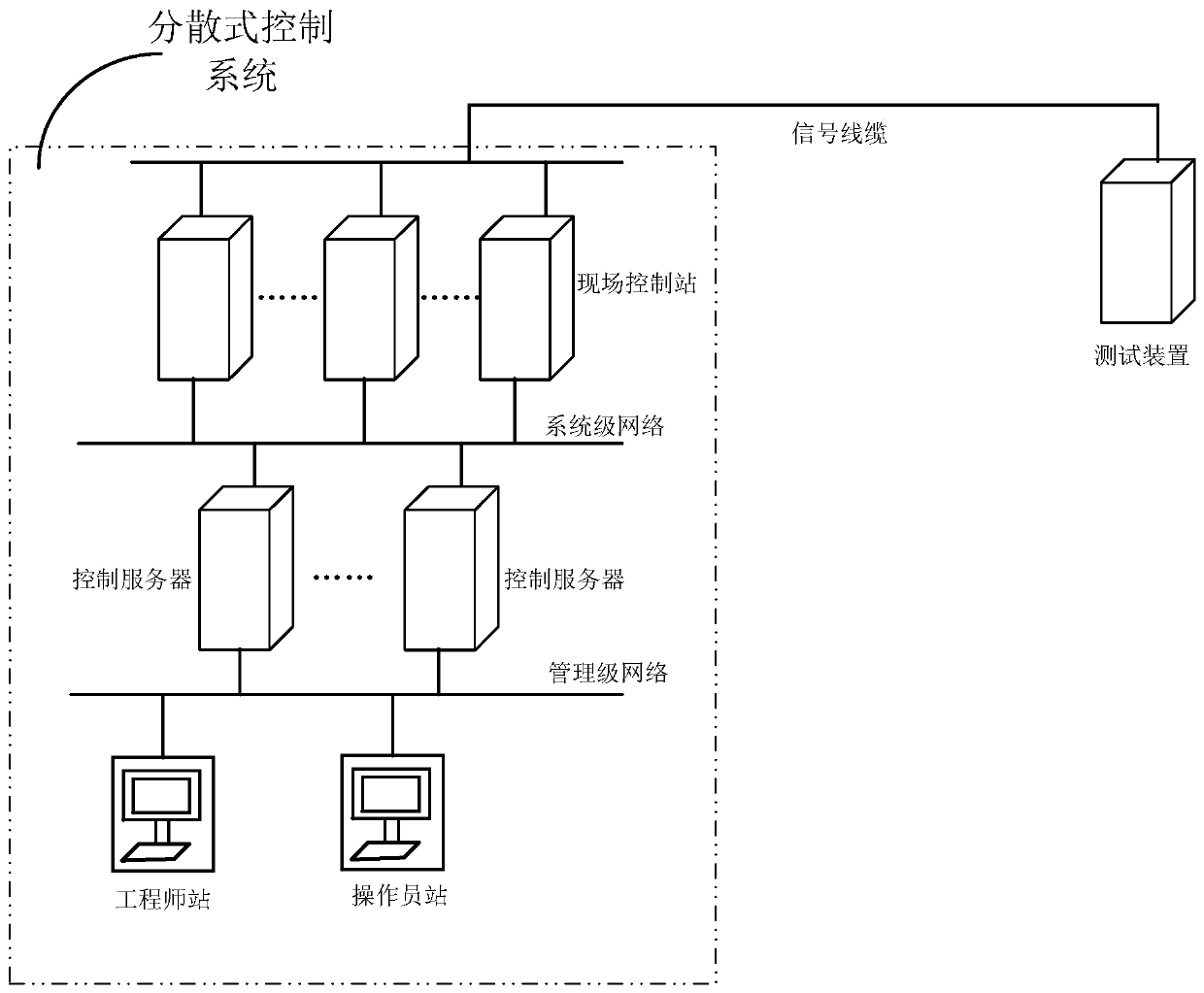

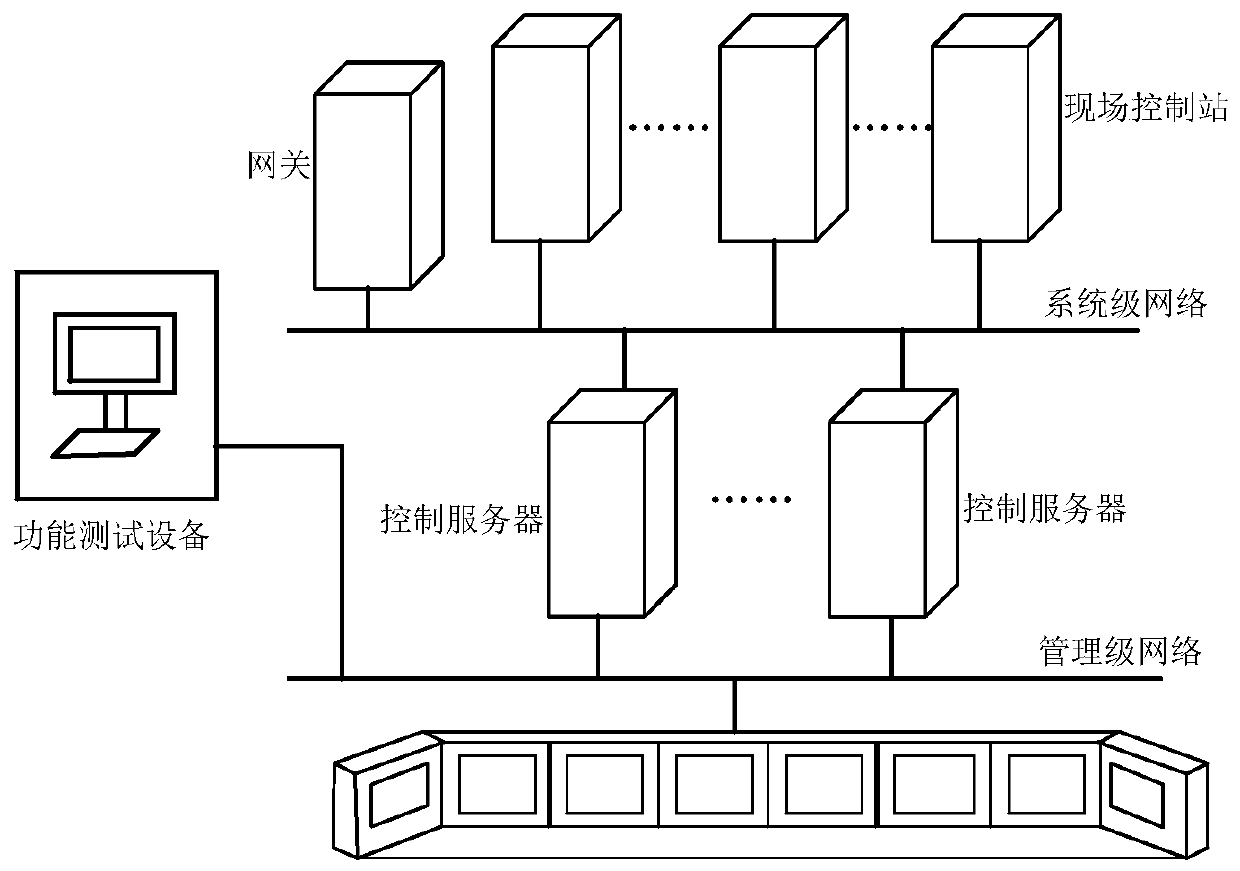

[0034] figure 2 It is a schematic structural diagram showing the function test system of the distributed control system according to Embodiment 1 of the present invention.

[0035] refer to figure 2 , the function test system of the distributed control system may include the distributed control system and the function test equipment of the distributed control system, and the distributed control system includes one or more control servers and one or more field control stations, and multiple execution device ( figure 2 not shown in ), etc., the execution equipment may be, for example, switch equipment, communication equipment and sensors. The functional testing equipment is connected to one or more control servers through the management level network of the distributed control system, and the one or more control servers are connected to one or more field control stations through the system level network. One field control station controls one or more execution devices. Th...

Embodiment 2

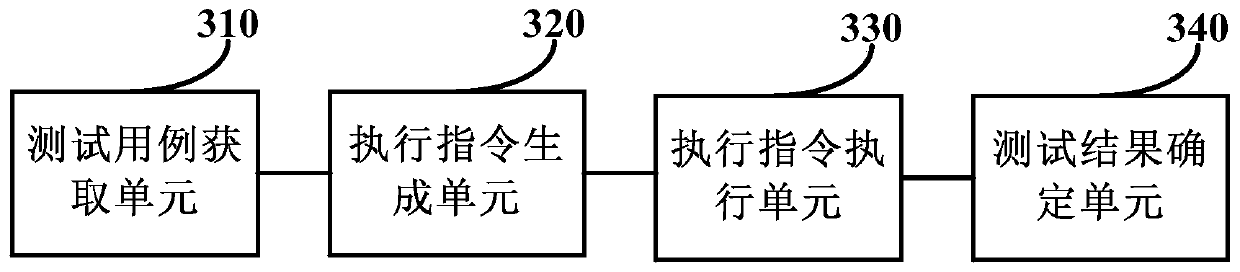

[0052] Figure 6 It is a flow chart showing the function testing method of the distributed control system according to the second embodiment of the present invention. by including as image 3 The shown functional test equipment performs the method. Among them, the location of functional test equipment in the distributed control system can be found in figure 2 ,based on figure 2 The functional testing system of the distributed control system is used to illustrate the functional testing method of the distributed control system according to the second embodiment of the present invention. The distributed control system in the embodiment of the present invention is described in detail by taking the DCS (Distributed Control System) control system as an example, and the processing of other distributed control systems may be the same or similar, and will not be repeated here.

[0053] refer to Figure 6 , in step S610, obtain a test case including a plurality of test step data,...

Embodiment 3

[0074] Figure 7 It is a flow chart showing the function testing method of the distributed control system according to Embodiment 3 of the present invention, and the embodiment can be regarded as Figure 6 Another specific implementation scheme of .

[0075] refer to Figure 7 , in step S710, obtain a test case including a plurality of test step data, the test step data includes step sequence number, execution operation, execution device, input data and expected output result data.

[0076] Wherein, the step content of the above-mentioned step S710 is the same as that of the step S610 in the first embodiment above, and will not be repeated here.

[0077] In step S720, a predetermined number of test arrays are determined according to the expected output result data and input data in each of the test step data.

[0078] Among the predetermined number of test arrays, one or more test arrays can be set according to actual conditions.

[0079] In implementation, in order to fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com