Nano infrared electric heating ring

An electric heating coil, nanotechnology, applied in the direction of ohmic resistance heating parts, heating element material, heating element shape, etc., can solve the problem that the heating coil cannot be equipped with a tight heat insulation device, shorten the service life, and large energy loss, etc., to avoid Heat energy loss and waste, energy saving, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

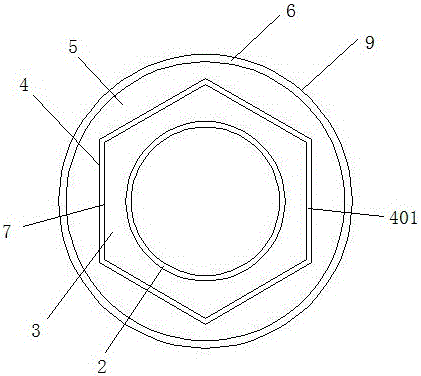

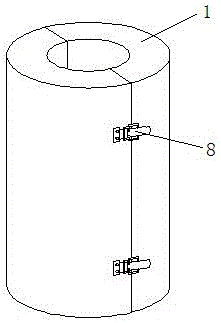

[0015] figure 1 and figure 2 A nano-infrared heating coil shown includes a main body 1 of the heating coil, and the main body 1 of the heating coil includes a far-infrared coating 2, a heat conducting layer 3, a nano-electric heating layer 4, a heat insulating layer 5 and a casing 6 from the inside to the outside, The main body of the electric heating coil is cylindrical in shape; the nano-electric heating layer 4 is spliced by several nano-carbon fiber heating plates 401, and the space between the nano-electric heating layer 4 and the heat insulation layer 5 is coated with high-temperature resistant and flame-retardant glass glue; the heat-conducting layer 3 A silver layer 7 is plated between the nano electric heating layer 4; the electric heating ring main body 1 is divided into two symmetrical parts along the cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com