Threaded Inserts

A technology of inserts and external threads, which is applied in the direction of threaded fasteners, screws, nuts, etc., which can solve the problems of limited application and the inability of ferrules to be used at high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

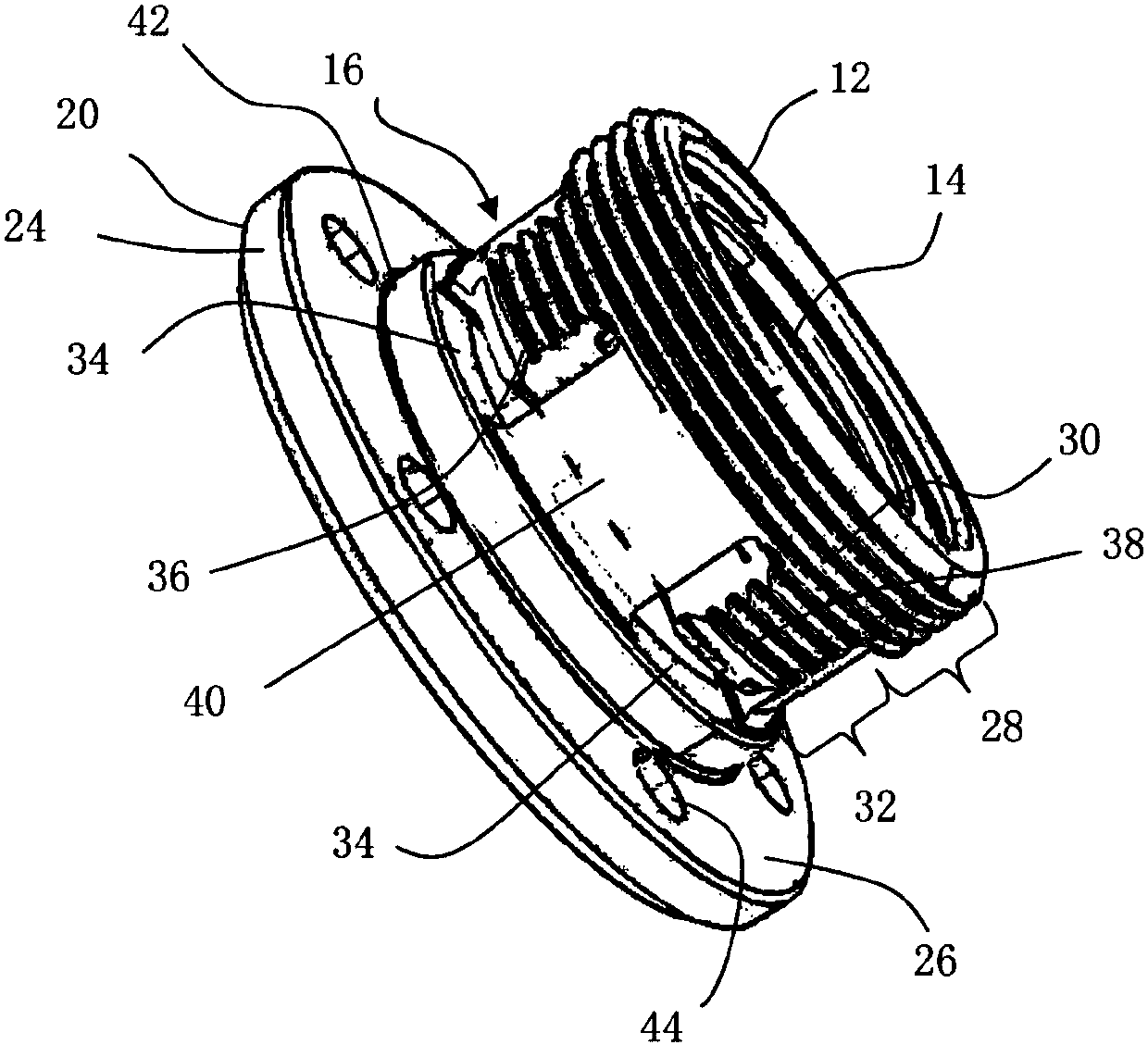

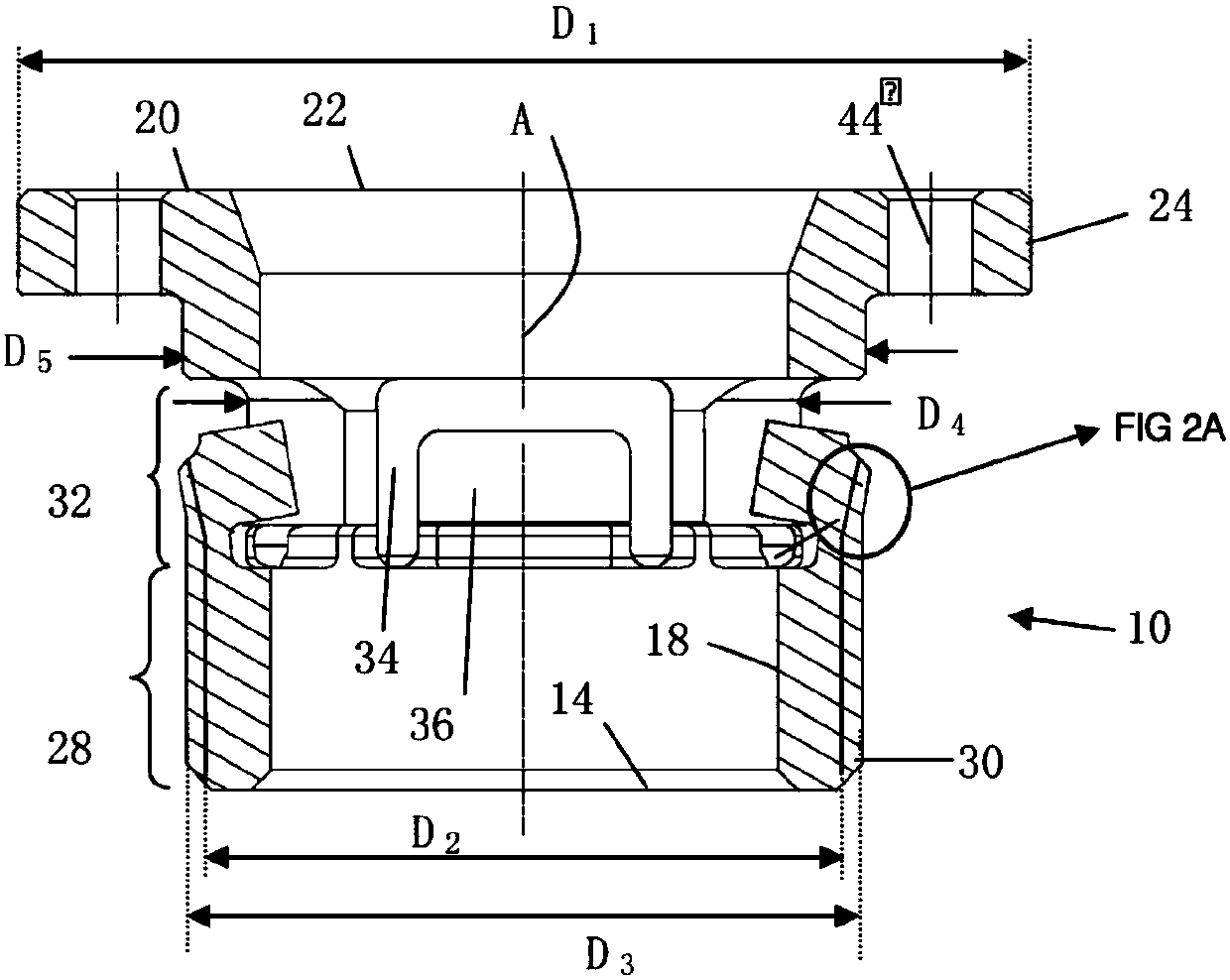

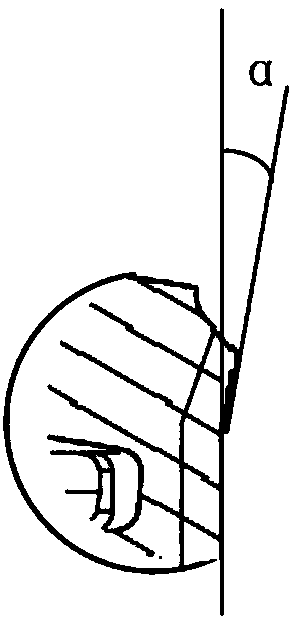

[0024] figure 1 and figure 2 shown for inserting into a threaded hole T ( image 3 ) of the insert 10 in the workpiece S. The insert 10 has an axis of rotation A and also includes a first end 12 defining a circular opening 14 , a cylindrical barrel 16 having an inner wall 18 and an outer wall, and a second end 20 defining a circular opening 22 . In another embodiment, the opening 22 may be non-circular, for example, in order to achieve the function of rotation. The barrel of the insert is used for inserting a shaft through the insert 10 . The inner wall 18 may be cylindrical, or may include a fool-proofing that matches the shape of the shaft. The second end is formed with an outer diameter of D 1 an enlarged flange 24 having a surface 26 towards the first end 12 for abutment against an element to be assembled and held on the workpiece, for example a bearing ring mounted on a rotating shaft . The outer diameter D of the flange 1 Greater than any other outer diameter o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap