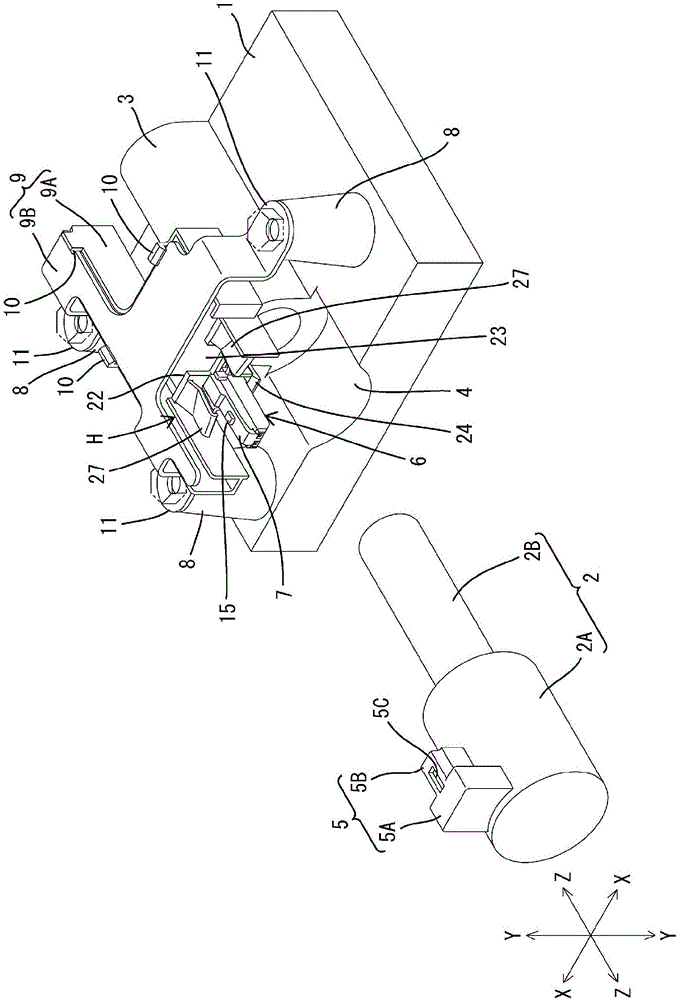

Connector with alignment function

A connector and function technology, which is applied in the direction of vehicle connectors, connections, and parts of connecting devices, etc., can solve the problems of assembly operation obstacles, reduced operation efficiency, and complex composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

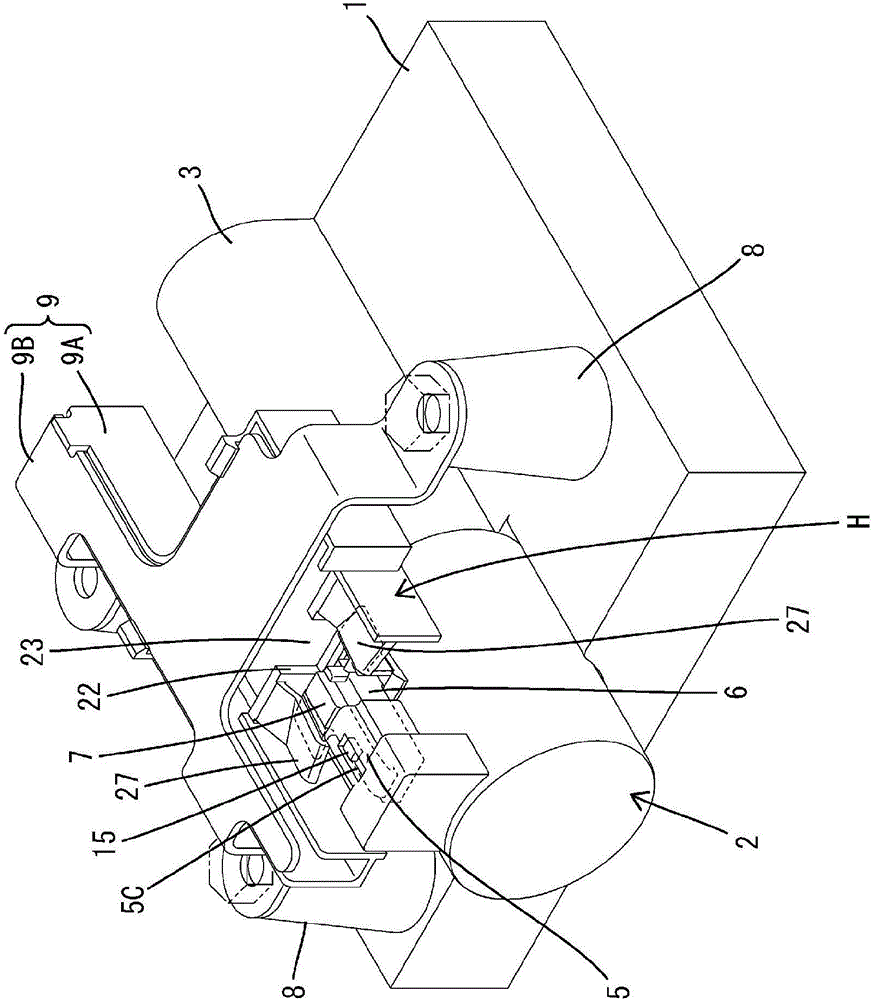

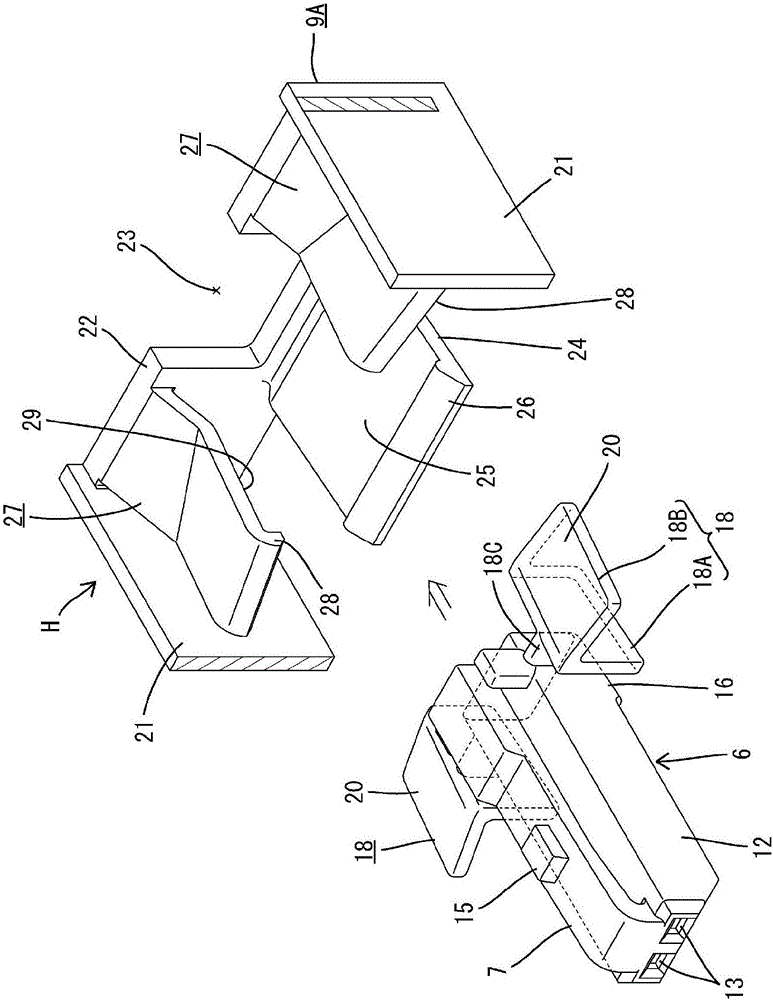

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described.

[0018] (1) In the connector with an alignment function of the present invention, it is preferable that the first connector is attached to the connector in a state capable of moving along the Z-axis direction, which is the fitting direction of the first and second connectors. the standoff.

[0019] When there is a deviation of the assembly device in the Z-axis direction between the first and second connectors, even if the second connector moves the specified fitting stroke, the two connectors will not achieve formal mating, and the lock cannot be used. The situation where the arm is locked, etc. However, according to the above-mentioned structure, since the first connector is mounted on the holder in a state capable of moving along the Z-axis direction, it is possible to absorb the deviation of the assembly device in the Z-axis direction, so that the two connectors can reliably reach the formal mating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com