Composite shoe sole

A technology of compound sole and surface buckle, applied in sole, footwear, application and other directions, can solve problems such as hindering production scale, occupying luggage space, waste, etc., to simplify the molding process, increase comfort, and ensure the effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

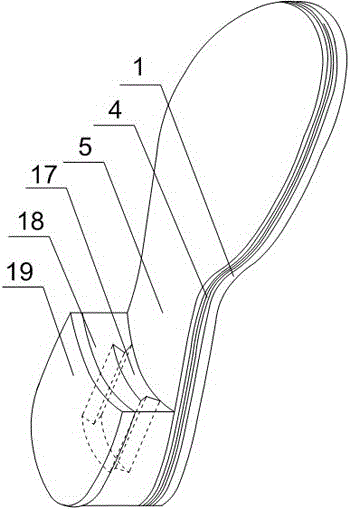

[0032] like figure 1 , figure 2 and Image 6 As shown, this embodiment includes an outsole 5 and a midsole 1, and a surface buckle 4 is provided on the inner side of the outline of the upper surface of the outsole 5, and the outsole 5 passes through the surface buckle 4 and the lower surface of the midsole 1. Card access. In the prior art, when the composite sole is formed, the midsole, the outsole and the heel need to be synthesized by a large amount of adhesive, and the storage of a large amount of chemical reagents leads to the matching of hardware and software in the molding workshop. The standard required for facilities is higher, that is, a higher level of fire protection and electricity consumption is required in the workshop, which greatly increases the production cost in the molding workshop; and in response to this problem, the inventor changed the implementation in the traditional synthesis process and abandoned the existing In the operation mode of bonding and ...

Embodiment 2

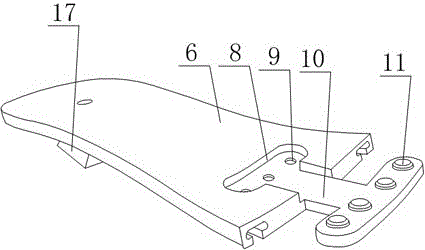

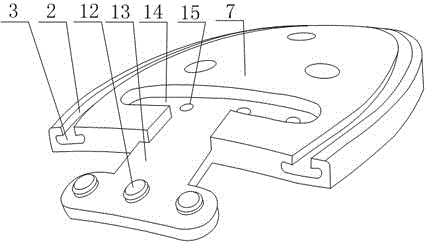

[0035] like Figures 1~3 As shown, this embodiment includes a midsole rear section 6 and a midsole front section 7, the upper wall of the midsole rear section 6 is punched to form a fastener I, and the lower wall of the midsole front section 7 is punched to form a fastener II , the rear section 6 of the midsole and the front section 7 of the midsole form the midsole 1 through the cooperation of the fastener I and the fastener II. In view of the traditional shoe manufacturing process, the inventor has improved the traditional shoe sole manufacturing method, that is, a modular design is adopted. The movable connection between the heel, the outsole, the midsole and the upper greatly simplifies the molding process of the shoe, and even does not require a special molding workshop, the user can make the combination by himself, that is, for women's shoes, according to whether there is or not. The heel is divided into flat shoes and shoes with heels. When switching between flat shoes...

Embodiment 3

[0043] like Figure 5 and Image 6 As shown, on the basis of Embodiment 1, the longitudinal section of the surface buckle 4 is an "I" shape or a "T" shape. The surface buckle 4 is used as a connecting piece. Under the premise of maintaining the stable connection between the midsole 1 and the outsole 5, the surface buckle 4 with a "T"-shaped longitudinal cross-section is selected, that is, the surface buckle 4 includes a locking groove respectively. 3. The horizontal section and the vertical section matched with the extrusion groove 2 can realize a seamless connection between the midsole 1 and the outsole 5, and prevent the air remaining between the outsole 5 and the midsole 1 from breeding bacteria.

[0044] Among them, the surface buckle 4 whose longitudinal section is "I" shape is preferably selected, so that the surface buckle 4 is divided into three parts: an upper horizontal section, a middle vertical section and a lower horizontal section, wherein the upper horizontal s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap